Within modern society, PCB electronics have become common in various technologies, including smartphones and smart speakers. Most electronic devices use printed circuit boards.

Therefore, the PCB assembly (PCBA) process is crucial so these technologies can function. However, it can be time-consuming.

This time can be even longer when different components are needed to manufacture the board. PCB assembly subcontracting offers a solution.

Many electronics manufacturers subcontract PCB production, sometimes using multiple subcontractors simultaneously, depending on the available services.

For example, this may occur if a subcontractor only helps with specific parts of the production process instead of all of it. In this instance, you may need several subcontractors to complete manufacturing as they each work on specific aspects of the process.

This blog explains what happens when you subcontract a PCB assembly and how that can benefit you and your company.

What does Subcontracting a PCB assembly involve?

When someone subcontracts a printed circuit board assembly (PCBA) process, they use an external company to make the PCB. A subcontractor is a trading company or a manufacturer and may be involved in all or only part of the production process.

This team of experts is responsible for making the PCBs and their associated obligations. The experts need to be within an electronics business.

A contract establishes the subcontractor’s responsibilities and tasks.

What is the role of the PCB assembly subcontractor?

When a PCB assembly contractor is involved in the production process, they offer support through various stages to aid in the manufacturing of quality PCBs for their clients. To do this, they use specialists with specific equipment to ensure everything runs smoothly.

They can provide support for the following:

- The designing stage

- Surface assembly

- Compliance testing

- Potting

- Quality control

Quality control can occur throughout manufacturing to reduce the likelihood of PCBs not working upon completion. PCB assembly technicians can perform various tests and inspections, such as automated optical inspections (AOI) and X-rays, to ensure quality PCBs are produced and distributed to clients. These quality control steps help ensure the finished product is reliable and the fail rate is low.

The support offered will depend on the services you receive from a subcontractor, which can vary from firm to firm.

A subcontractor may also provide documents to their clients. These documents can give the client information about the different processes and implementations occurring through manufacturing, so they are helpful to have and reference.

Why should you subcontract a PCB assembly?

Production efficiency

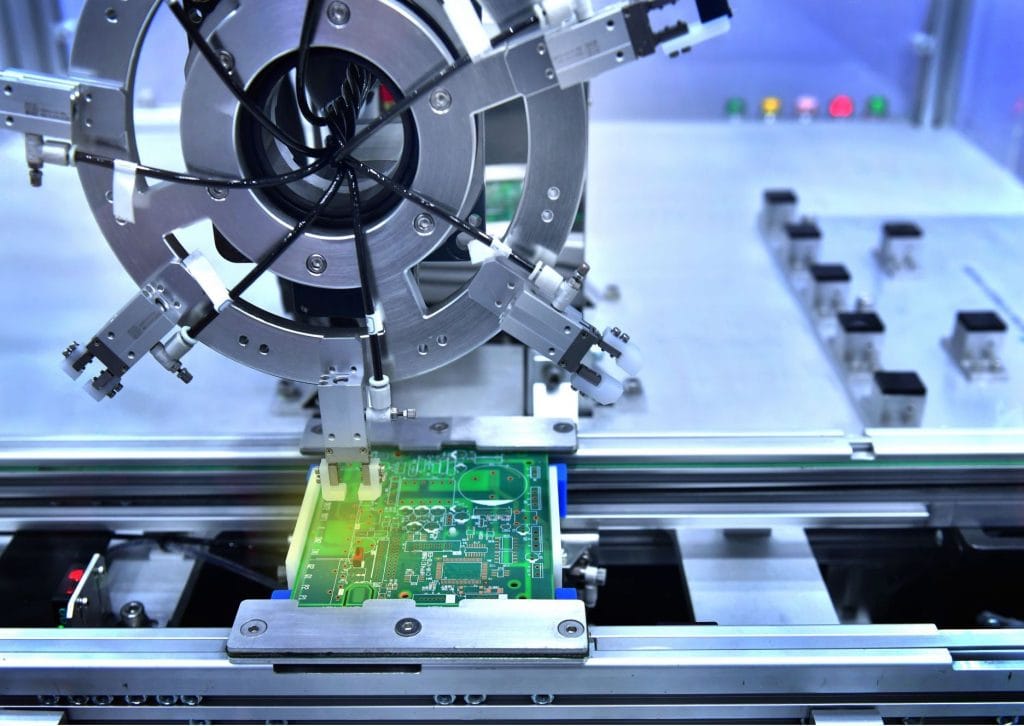

Subcontractors use machines made for PCB production. The machines can therefore mass-produce PCBs, making more in a shorter timeframe and increasing production efficiency. PCBs can also be cheaper because a PCB assembly manufacturer can mass-produce them.

Accuracy

Mass-producing PCBs can be done through replication when someone wants multiple identical PCBs. Machines can replicate these devices quickly and increase the manufacturing process’s accuracy, making ineffective printed circuit boards less likely upon completion.

Time efficiency in the designing phase

PCB design is a crucial part of the production process. The design must be correct. If not, it won’t work as it should.

Allowing a PCB assembly company to manufacture the boards enables them to ensure compatibility between the required components and the design. This compatibility can then reduce the time required in production.

Easier access to high-quality materials

Subcontractors have access to higher-quality materials to make PCBs, compared to the poorer-quality counterparts in many of the PCBs available on the market. They can also purchase these materials cheaper due to bulk buying so that they can produce high-quality PCBs at a lower production cost.

Are there any disadvantages to working with subcontractors?

More expensive

Whilst a PCB assembly subcontract can lead to cheaper materials, you still request a service from another supplier. Therefore, you must pay for this service and invest in their work.

The rate a subcontractor may charge will differ depending on the firm you wish to use, but this amount may be more expensive than the cost of employing another staff member within your business.

Less control of the project

Subcontractors are part of an external firm, meaning they are not part of your company. Therefore, manufacturing these boards is done outside your business if you subcontract PCB production.

When your organisation makes their PCBs, they have complete control over manufacturing. However, some power is lost as subcontractors are outside your company. You may be involved in this process, but the subcontractor would have control instead of your business.

It can be even more difficult to manage production when using multiple subcontractors, though this is sometimes necessary. Verifying each stage in the manufacturing process becomes more challenging, which can also impact the quality of the finished product.

Relying on a team you know nothing-to-very little about

As previously noted, subcontractors are, at the heart of it, external hires. So whereas previously your company’s PCB assemblers may have produced the boards, they will now be manufactured by individuals about whom you may have limited knowledge.

This uncertainty means you may subcontract people less passionate or dedicated than your team and, therefore, may be less motivated to produce the PCBs as fast or high quality as you want them to be.

PCBs are not the only thing forming our technology. The development of artificial intelligence (AI) is changing how we create and utilise technology and can currently be found in our homes and cars, to name but a few locations. It is also altering the electronics industry.

Whilst it is currently unclear how large the impact of AI in electronics will have, its potential to alter this industry may influence subcontracting and the assembly process, such as identifying errors within production.

If you have any questions about PCB assembly, contact Altimex today. We are here to help with your electronic needs and are always looking at ways to offer the best services, whether through new technology or AI. See how we can support you and your electronics.