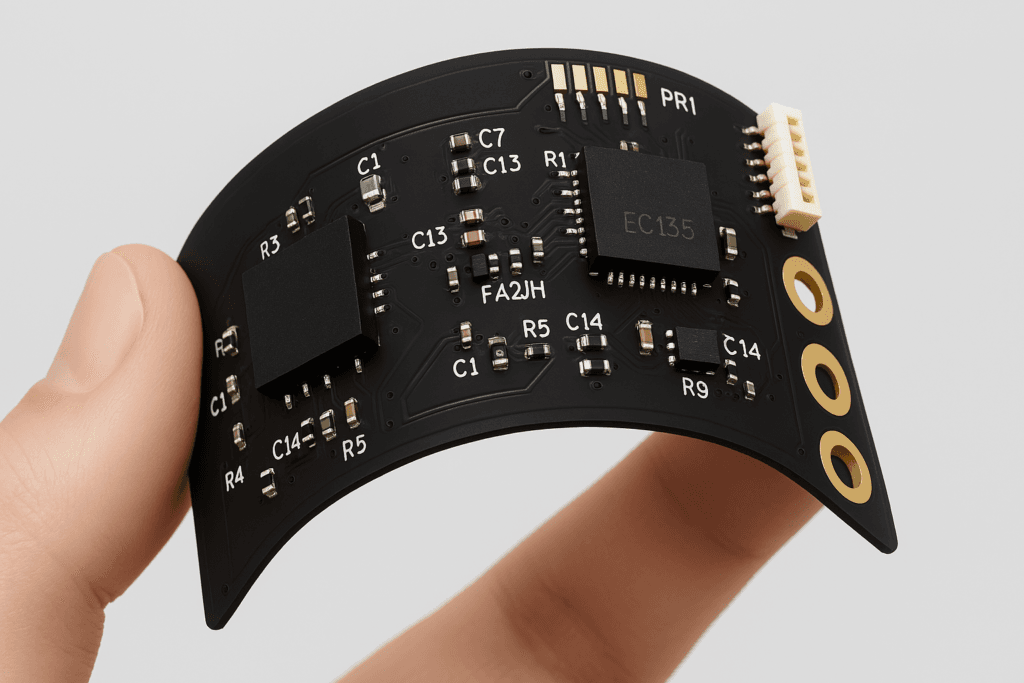

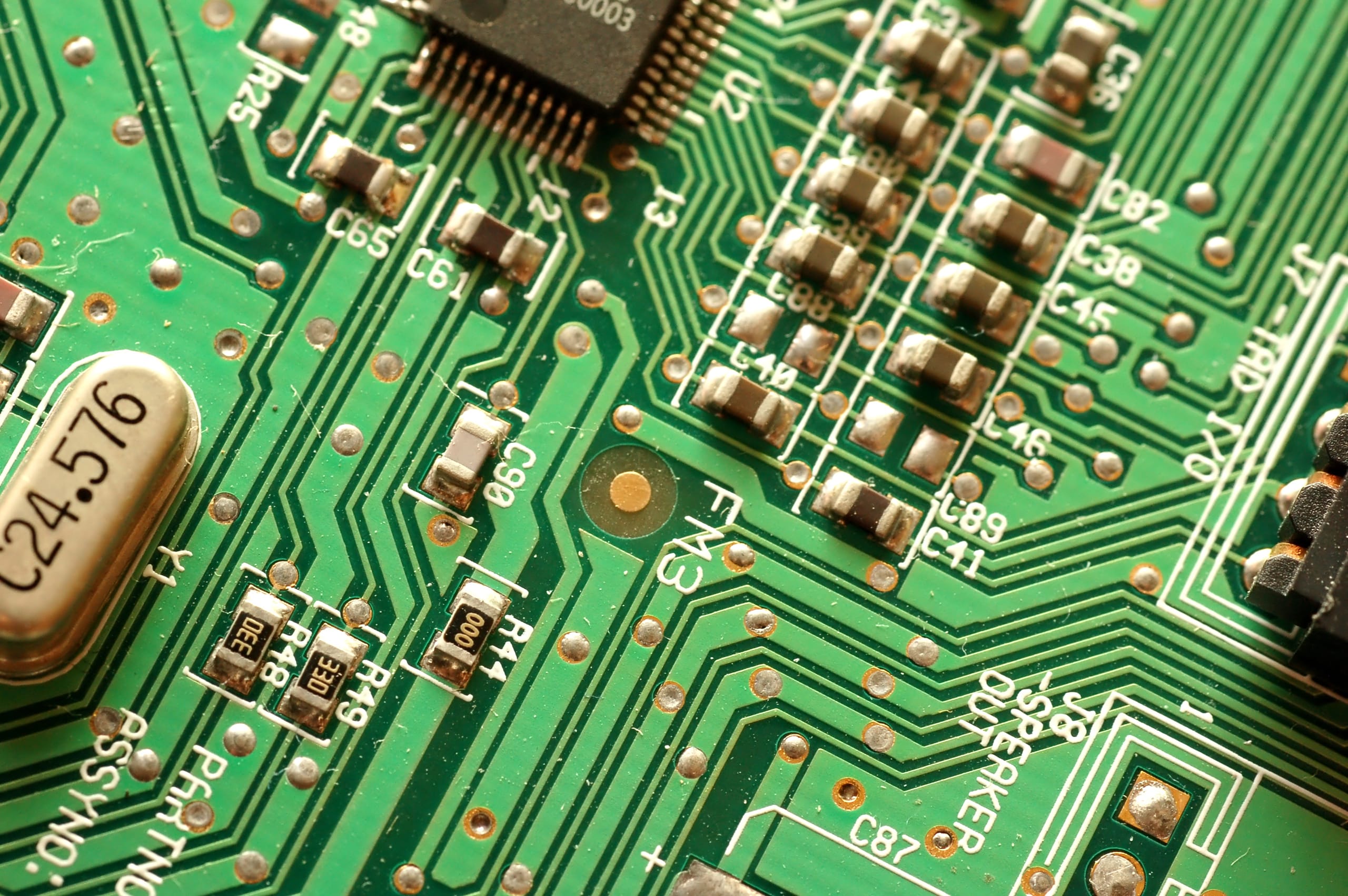

What are Flexible PCBs?

Flexible PCBs (printed circuit boards) are circuits built on bendable materials, such as polyimide or polyester films. This makes them different from traditional rigid PCBs, as they can be bent, twisted, and folded without breaking.

Their flexibility allows them to be used in applications where space is limited or where the device shape is irregular. You’ll often find flexible PCBs in medical devices, wearables, automotive systems, and consumer electronics.

Flexible PCBs offer several advantages, including reduced weight, space-saving designs, and improved durability. They also perform well in dynamic environments, as they can withstand vibrations and movement, enhancing overall reliability.

Interested In Flexible PCB Manufacturing?

Get in touch with us and a member of our team will reach out to you.

Either use the contact form on our website or call us on +44 1829 741262

Proud to have worked with

Why Work With Altimex?

4-Star Certified Service Desk

Trusted & Approved Installers

Tailored

Solutions

Building Long-Term Partnerships

Certified & Experienced Team

What are Flexible PBCs Used For?

Flexible PCBs are used across a wide range of industries due to their adaptability, lightweight nature, and ability to fit into tight or complex spaces, such as:

- Foldable smartphones

- Laptops

- Pacemakers and defibrillators

- Wearable health monitors

- Automotive dashboard displays

- Airbag systems

- Missile guidance systems

Benefits Of Choosing Flexible PCBs

Compact and Lightweight

Complex

Geometries

Cost

Savings

Heat

Dissipation

Custom Flexible PCB Manufacturing

At Altimex, we offer expert custom flexible PCB manufacturing tailored to your specific requirements from initial concept through to final production.

Our capabilities include single- and double-sided flex circuits, multi-layer flexible designs, and rigid-flex combinations. We specialise in producing compact, lightweight, and highly durable PCBs that perform reliably in demanding environments.

Over 25 years in the industry.

From manufacturing and providing multiple electronic designs as well as fibre optics, Altimex consistently delivers high-quality award-winning solutions.

- Award Winning Team

- Industry Leading Experts

- Quality one-stop solutions for all

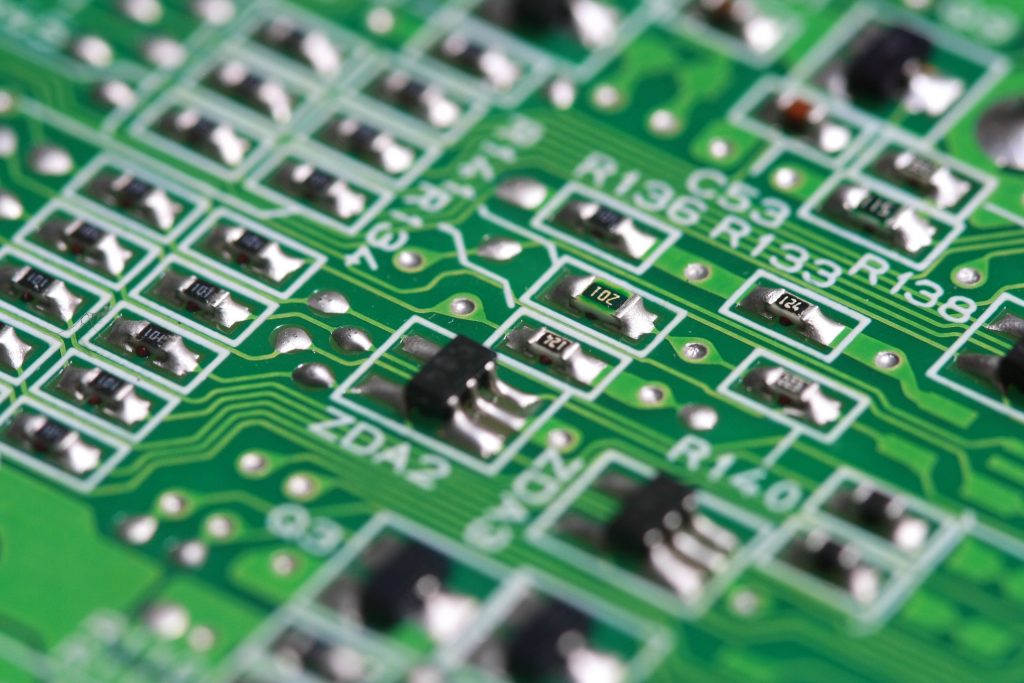

Multilayer Flexible PCBs

At Altimex, we specialise in manufacturing multi-layer flexible PCBs, offering advanced solutions for complex electronic applications.

Our multi-layer flex circuits provide increased routing density, improved signal integrity, and enhanced performance in compact, lightweight formats.

We work closely with our clients from concept to completion, ensuring every design meets exact requirements and industry standards. With cutting-edge technology and a commitment to quality, we deliver dependable, space-saving solutions tailored to your specific needs.

Get In Touch Today For Flexible PCB Manufacturing

If you have a query about our services or feel like we could help you, please get in touch by filling the form out below or by calling us on 01829 741 262.

Frequently Asked Questions

A flexible PCB (Printed Circuit Board) is a circuit made on a flexible substrate, typically polyimide or a similar material. Unlike rigid PCBs, flexible PCBs can bend, fold, and twist, making them ideal for compact or irregularly shaped devices. They offer excellent space efficiency and can reduce the need for connectors or cables. Flexible PCBs are commonly used in medical devices, consumer electronics, aerospace, and automotive applications where reliability and compact design are essential.

Flexible PCBs offer numerous advantages, including space and weight savings, improved reliability in dynamic environments, and greater design flexibility. They eliminate the need for connectors and wiring between separate rigid boards, reducing assembly time and failure points. They can also be folded into 3D shapes, allowing for compact product designs. Additionally, they perform well under vibration and thermal stress, making them suitable for harsh conditions. These benefits make them popular in industries like aerospace, medical, automotive, and wearable technology.

Flexible PCBs are used in a wide range of applications, especially where space is limited or the circuit must bend. Common uses include smartphones, tablets, medical devices, wearable tech, automotive sensors, and aerospace systems. They are also popular in cameras, LED lighting systems, and industrial equipment. In any scenario requiring compact, lightweight, and reliable circuitry that can handle motion or mechanical stress, flexible PCBs are often the preferred choice.

Flexible PCBs are typically made using polyimide or polyester films as the base substrate due to their flexibility and heat resistance. Copper is used for the conductive traces, while coverlays or solder masks protect the circuit and provide insulation. Adhesives may also be used between layers, though adhesive-less constructions are available for high-performance applications. The choice of materials depends on the environmental conditions the PCB will face, including temperature, bending frequency, and exposure to moisture or chemicals.

Single-sided flexible PCBs have one layer of conductive material, usually copper, and are used in simple applications. Multi-layer flexible PCBs, on the other hand, consist of multiple conductive layers separated by insulating material. These allow for more complex circuit designs, increased component density, and better performance. Multi-layer flexible PCBs are ideal for high-speed or high-reliability applications such as in aerospace, medical, and advanced consumer electronics where space is limited but performance is critical.

Rigid-flex PCBs combine both flexible and rigid sections into one unified board. This allows the rigid areas to support components while the flexible areas provide connection and mobility. They are ideal for applications requiring both stability and movement, such as foldable devices or systems with moving parts. Rigid-flex PCBs reduce the need for connectors, improve signal integrity, and save space. They are commonly used in medical implants, military equipment, aerospace controls, and compact consumer electronics.

Yes, flexible PCBs are designed to be highly durable, especially in environments involving constant movement, vibration, or bending. Materials like polyimide provide excellent thermal stability, mechanical strength, and chemical resistance. Proper design also ensures that stress is distributed evenly to prevent cracking or fatigue. When manufactured and assembled correctly, flexible PCBs can last as longer, or even longer, than rigid PCBs in many demanding applications, making them suitable for critical systems in aerospace, medical, and industrial fields.

Absolutely. Flexible PCBs are highly customisable and can be tailored to meet specific design requirements, including unique shapes, sizes, layer counts, and performance characteristics. Manufacturers like Altimex work closely with clients to design and build bespoke flexible circuits that meet strict standards for reliability, durability, and electrical performance. Customisation includes impedance control, shielding, via placement, and component integration, enabling engineers to design compact, high-performance products with fewer limitations than rigid alternatives.