Designing Printed Circuit Boards (PCBs) for the aviation sector is essential to providing safety and operational success. With aircraft systems facing extreme conditions such as vibration, temperature fluctuations, and electromagnetic interference (EMI), every design element must meet stringent requirements. Poor design can lead to system failures, creating risks for passengers and operational reliability. This guide outlines principles for engineers and designers to develop aviation PCBs that consistently meet performance and safety expectations.

This guide introduces eight rules for producing PCBs that meet aviation-specific requirements. These principles help engineers and designers improve functionality, reduce failure rates, and meet industry standards. Each rule addresses an essential aspect of PCB design for aviation to help achieve consistent outcomes.

1. Comply with Industry Standards

To effectively incorporate industry standards like DO-254 and AS9100, identify their requirements during planning.

Keep detailed records of decisions made throughout the design process for audits and approvals. Early collaboration with certification bodies means designs meet compliance goals, preventing delays and costly revisions.

Incorporating compliance requirements early in the design process can save significant time and resources later. Documenting design decisions according to these standards streamlines certification processes and reduces the risk of delays. Ignoring compliance can lead to operational risks, including system failures or failure to achieve certification, resulting in costly redesigns or project setbacks.

Following these specifications, designers produce PCBs that meet the high expectations of the aviation industry and cover situations such as electromagnetic interference control.

2. Minimise Electromagnetic Interference

Effective PCB design reduces EMI by incorporating strategies such as proper grounding, shielding, and controlled impedance. Techniques like segregating high-frequency components from low-frequency ones and carefully routing signal traces help reduce interference. Shielding layers or enclosures provide additional protection against external and internal EMI sources. Controlled impedance, achieved through accurate trace design and material selection, supports consistent signal transmission.

Addressing this during the design phase helps avoid such issues, resulting in more reliable PCB aviation electronics.

3. Use Thermal Management Techniques

These techniques are an essential aspect of aviation PCB design, as excessive heat can damage components and reduce their operational lifespan. Aviation environments often involve high-power electronics and limited cooling options, requiring efficient heat dissipation strategies.

Thermal management techniques such as using heat sinks, thermal vias, and selecting materials with high thermal conductivity help manage heat effectively. Thermal simulation during the design phase identifies potential hotspots and refines layouts to improve heat distribution. Incorporating copper pours or dedicated thermal layers can improve thermal performance.

Taking steps with thermal management early reduces risks and supports dependable performance in aviation electronics.

4. Ensure Vibration and Shock Resistance

Poor resistance to shock and vibration can lead to component failures, which may compromise system performance. Designing for vibration and shock involves thoughtful component placement, secure mounting, and the use of specialised materials.

Flexible PCBs are an effective solution for managing mechanical stress, as they can bend and flex without breaking. Additionally, reinforcing solder joints and securing larger components with adhesives or brackets help improve stability. Testing methods such as vibration tables and shock simulations validate the design’s durability under real-world conditions, and prioritising vibration resistance during design helps create reliable electronics.

5. Conduct Power Integrity Analysis

PCB design needs power integrity to function, meaning a strong power distribution network (PDN) is required to maintain voltage changes and sensitive electronics. Key techniques for improving power integrity include designing proper power planes, strategically placing decoupling capacitors, and minimising trace inductance. Using tools like power integrity analysis software helps identify potential issues early in the design process. This allows engineers to optimise power flow and address inefficiencies before production. Managing power integrity effectively supports consistent functionality and reduces the risk of failure.

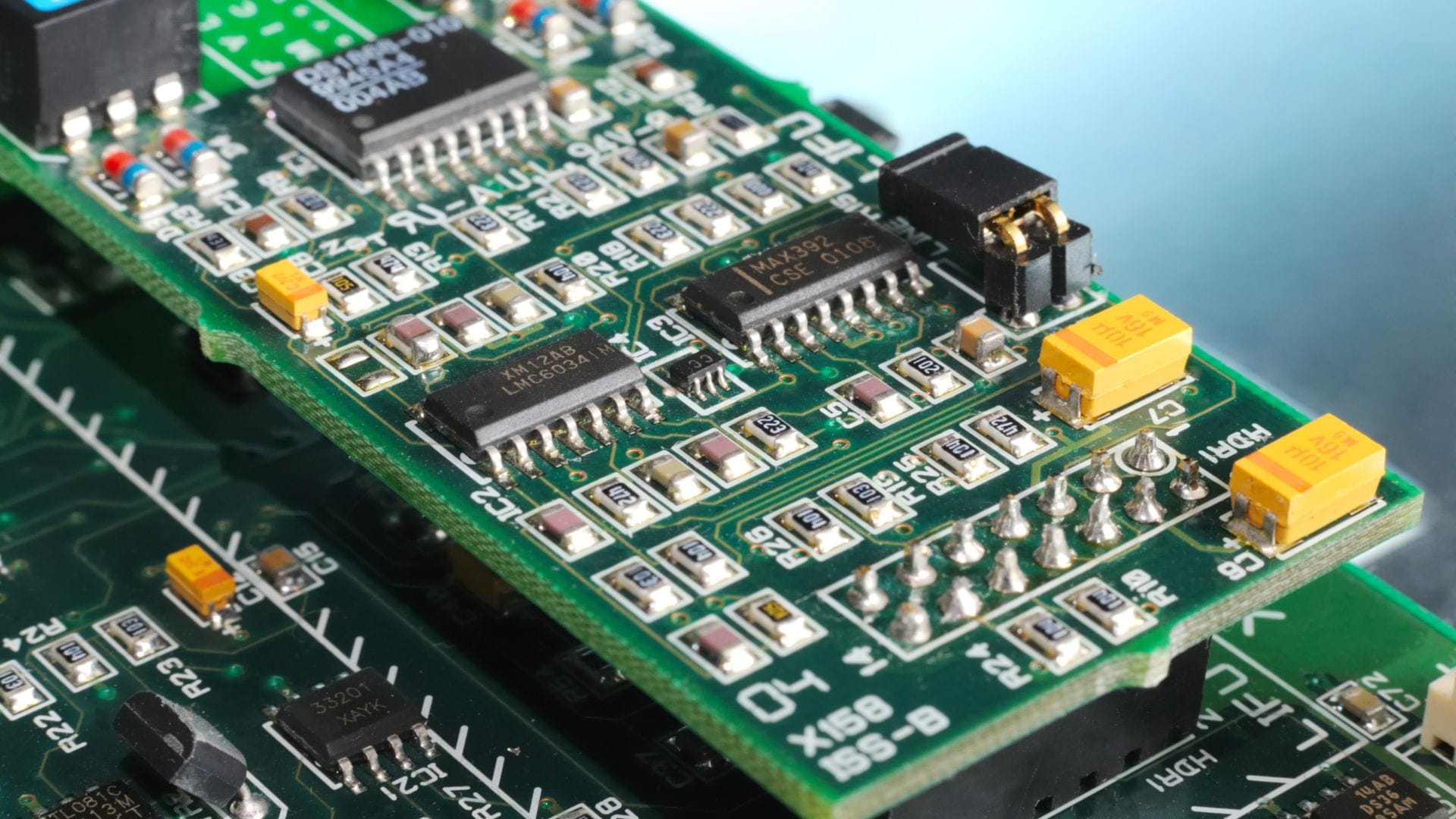

6. Design for Signal Integrity

Signal integrity is an essential aspect of aviation PCB design, especially for high-speed circuits where even minor disruptions can cause malfunctions. Poor signal quality causes crosstalk, signal reflections, and data errors, which are unacceptable in aviation systems.

To improve signal integrity in PCBs, designers can optimise trace routing by maintaining consistent trace widths, using shorter signal paths, and implementing proper spacing between traces. Additionally, the use of ground planes reduces noise and stabilises signal transmission. High-frequency signals benefit from impedance matching to minimise signal loss. Addressing this during the design phase helps achieve consistent performance and reliability in aviation electronics.

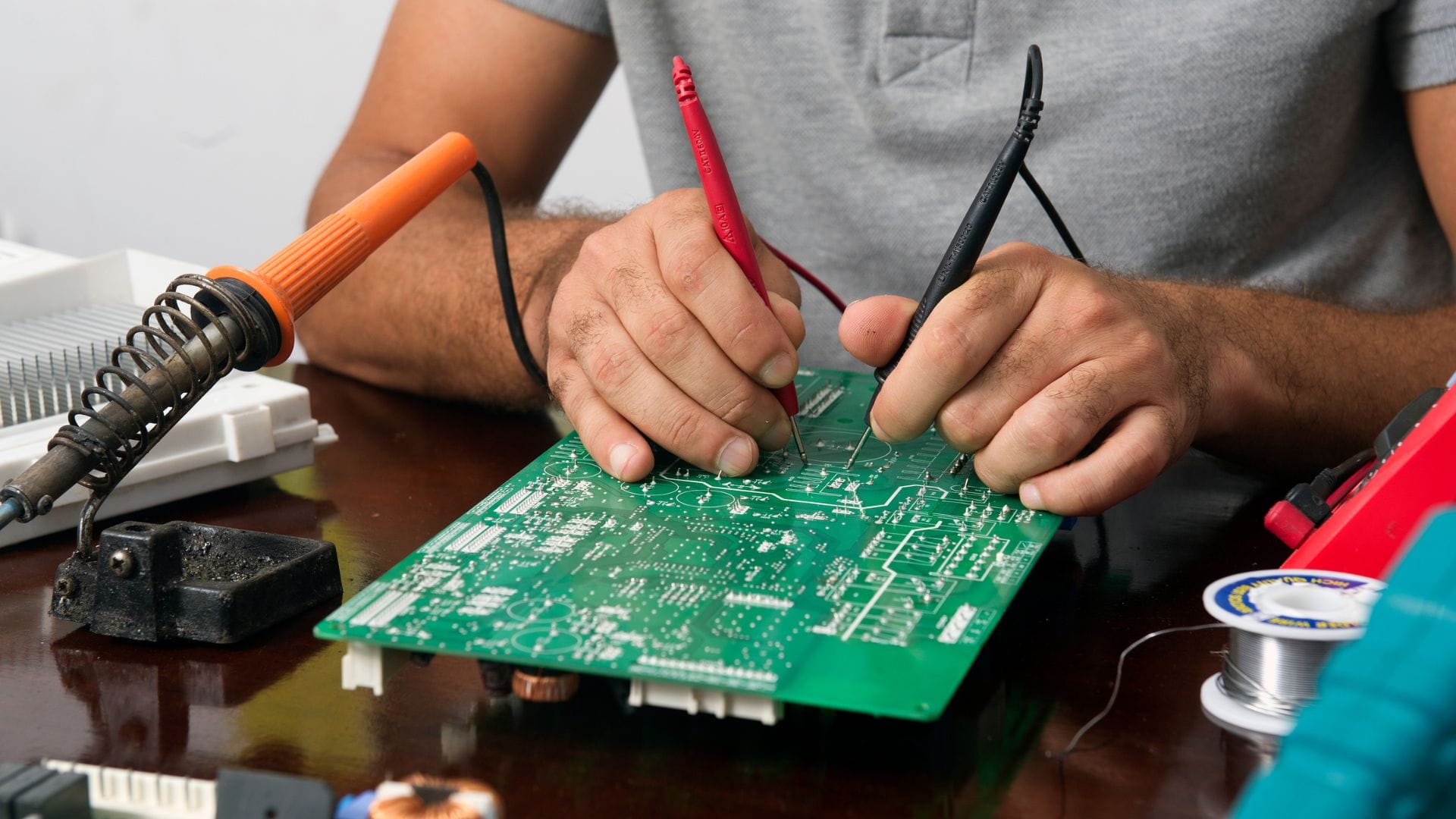

7. Conduct Robust Testing

Compliance validation is one way to make sure that PCBs meet performance and reliability standards. These efforts, with processes like thermal cycling to simulate extreme temperature conditions, vibration testing to evaluate mechanical stress resilience and electromagnetic compatibility (EMC) tests to make sure the board operates without interference.

Prototyping helps identify and resolve design issues before production, allowing engineers to refine layouts and validate real-world functionality. Automated testing tools further improve the efficiency and consistency of these processes, delivering reliable results that support the development of dependable aviation PCBs. Aviation PCB testing ensures these boards meet industry-specific requirements, reinforcing their safety and performance in critical applications.

8. Document and Trace Changes

Maintaining documentation and traceability is essential, it provides clear records of design changes, material specifications, and testing results. It supports compliance with industry standards and simplifies troubleshooting when issues arise. Tools for managing design revisions, such as version control systems, allow teams to track changes effectively and avoid inconsistencies. Documentation also improves collaboration between engineers, manufacturers, and other stakeholders, helping everyone work with the latest design iteration.

Traceability is particularly valuable for meeting regulatory requirements and investigating any failures during the lifecycle of the PCB. Consistent record-keeping supports long-term reliability and simplifies future updates or modifications.

Aviation PCB design requires precision, adherence to standards, and attention to detail. Staying updated on PCB advancements and refining design methods will help meet the sector’s changing demands. Altimex supports these efforts with advanced PCB assembly services.

If you’re looking for expert support in aviation PCBs, contact Altimex today. Our experience and commitment to excellence can help you achieve outstanding results for your next project.