Every project starts with a board, and so it usually helps to accept that the cost of PCB assembly can shift quite a lot before anything reaches production.

Many teams say the same thing, since the price often feels unpredictable at first glance, yet it tends to make far more sense once you break the work into smaller, practical steps. The point here is that each detail in a design pulls the price a little higher or a little lower, and that creates the spread you often see in early estimates.

For engineers and procurement managers, it’s almost a shared experience to look at two boards that seem fairly similar yet carry very different totals. That gap usually comes from design shape, layer count, component choice, or how many units you actually need, and each of these sits quite close to the final figure. In other words, you start to get a clearer feel for cost once you see how these parts interact.

Teams often say they want straight answers, and so this guide aims to give you something that feels more grounded than guesswork. Prototypes might be a bit higher per unit because setup time sits heavily on small batches, yet production runs usually settle into steadier patterns. As a matter of fact, once you understand how these elements behave, you can shape a budget with far more confidence.

Here, we walk through each factor in a steady, practical way, so you can approach PCB assembly pricing with a clearer, more relaxed view.

What Influences PCB Assembly Costs

Impact of PCB Complexity

PCB assembly board costs can rise or fall based on how easily a board moves through the assembly line, so complexity matters in a very practical sense rather than an abstract one. A layout with clear spacing and standard footprints usually passes through placement and inspection stages without delay, that is, machines can run at normal speed and operators intervene less often.

As component count increases, assembly time increases too, so every additional placement adds measurable time to the process. Fine pitch components slow placement and inspection, since alignment tolerances tighten and verification steps increase, which means more hands-on attention during build.

Complex boards do not cost more by default, yet they do require more time at specific stages, and that time directly affects assembly pricing. The relationship is straightforward, so designs that demand slower placement, extra inspection, or repeat handling will always cost more to assemble than simpler equivalents.

Number of Layers

Layer count does not directly change the act of assembly, yet it often affects how a board behaves once it reaches the assembly line, so it still matters in a practical way. Thicker or higher layer boards can hold heat differently during reflow, and that behaviour sometimes requires tighter process control during soldering.

Boards with higher layer counts also tend to appear in more complex designs, which means denser layouts, finer pitch components, or higher component counts, and that combination usually increases placement time and inspection effort. In that sense, layer count links to assembly cost indirectly, through the demands it places on the build rather than through the assembly process itself.

From an assembly perspective, the key point is not the number of layers alone, but what that layer count allows or forces the design to do. When higher-layer designs introduce tighter spacing or thermal sensitivity, assembly time rises, and the cost follows that change quite directly.

Board Size and Shape

Board size and outline affect assembly cost through how efficiently boards can be handled and processed on the line, so this factor tends to surface early in pricing discussions. Standard rectangular boards usually panelise cleanly and move through handling stages with minimal intervention, which keeps placement and inspection time under control.

Larger boards or irregular outlines reduce panel efficiency and can require additional handling during placement, reflow, or depanelisation. That extra handling adds time to the process, and time remains the main driver of assembly cost.

Small changes to the board outline can sometimes improve panel utilisation, which allows more units to be assembled in a single run. When that happens, assembly time per board drops, and pricing reflects that improvement.

Cost Differences Between Prototype and Production Runs

Small Batch Requirements

Small batch builds usually carry a higher cost per board, so this stage often raises questions during early planning. The reason is simple: the preparation work needed to start assembly does not shrink when quantities are low, and that effort is spread across only a few units.

Programming pick and place machines, loading feeders, setting up solder processes, and running initial checks all take the same amount of time whether the batch includes five boards or five hundred. When that fixed time sits across a small quantity, the unit cost rises accordingly.

From an assembly point of view, small batches are not inefficient, yet they are time-intensive relative to volume. Prototype builds exist to confirm layout, placement, and function before scaling, and the higher per-unit cost reflects that role rather than inefficiency in the process itself.

Setup and Tooling Expenses

Setup and tooling account for a fixed portion of PCB assembly cost, so they carry the most weight at the start of a build. Before the first board is assembled, machines need programming, feeders need loading, tooling needs fitting, and initial checks need completing. None of this work changes with quantity.

In short runs, that preparation time sits almost entirely within each unit price. In larger batches, the same effort spreads across many boards, which lowers the cost per unit without changing the work involved.

From a pricing point of view, this is why early quotes often look high and later production pricing looks more stable. The process stays consistent, yet the way fixed time is shared across volume changes how the cost appears.

How Component Selection Affects Pricing

Availability and Lead Times

Component availability affects PCB assembly pricing in a direct and practical way, so it needs clear attention during planning. When parts are readily available, assembly can proceed without interruption. When parts carry long lead times or limited stock, schedules extend, and costs rise through rescheduling, partial builds, or line downtime.

Prices for components may fluctuate, yet lead time tends to cause the bigger disruption. A delayed part can hold an entire build, which increases handling, storage, and planning overhead. In some cases, teams switch to alternative components to keep a project moving, and that change can introduce extra placement time or additional inspection steps.

From an assembly perspective, a stable component supply keeps costs and schedule predictable. Designs that rely on widely available parts usually move through quoting and build with fewer interruptions, which keeps assembly pricing consistent across both prototype and production runs.

Standard Versus Specialised Components

Component choice influences PCB assembly cost through how easily parts can be placed, soldered, and inspected, so the difference between standard and specialised components matters in day-to-day production. Standard resistors, capacitors, and connectors usually place at normal machine speed and pass inspection without additional checks, which keeps assembly time under control.

Specialised or non-standard components often introduce extra steps. Unusual package shapes, fine pitch leads, or parts that require manual placement slow the assembly process and increase inspection time. In some cases, these components need additional handling or dedicated checks, which adds labour to the build.

From an assembly perspective, standardisation reduces variation and keeps pricing predictable. Designs that rely heavily on specialised components tend to carry higher assembly costs, not through material price alone, but through the extra time required to place and verify each part.

The Role of Assembly Technology in Pricing

Surface Mount Assembly

Surface mount assembly is the most common method used in modern PCB assembly, so its cost behaviour tends to be consistent across many projects. Components are placed directly onto the board surface by automated equipment, which allows high placement speed and repeatable results.

Because the process relies heavily on automation, assembly time scales well as volume increases. Once machines are programmed and running, placement and soldering proceed with minimal variation, which keeps labour input low and pricing predictable across medium and larger batches.

From an assembly cost point of view, surface mount technology suits designs that prioritise density and repeatability. Boards built primarily with surface mount components usually move through the line efficiently, and that efficiency shows clearly in the final assembly cost.

Through Hole Assembly

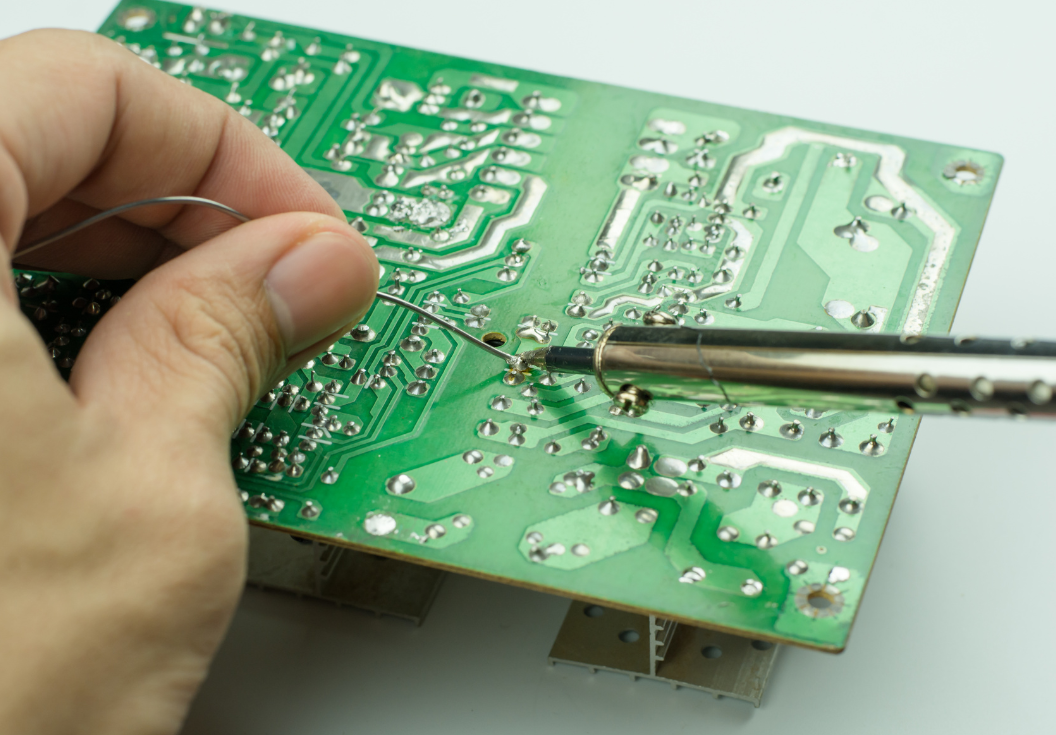

Through hole assembly generally carries a higher assembly cost, since the process involves more manual handling and slower soldering methods. Components pass through drilled holes and are either hand soldered or processed using wave soldering, both of which take longer than automated surface mount placement.

Each through hole component adds handling time during insertion and increases inspection effort, as joints need checking on both sides of the board. This additional labour becomes more noticeable as the number of leaded components rises.

From an assembly perspective, through hole technology remains useful where mechanical strength or durability matters, yet that benefit comes with increased build time. Designs that rely heavily on through hole parts typically show higher assembly costs due to the labour involved rather than the components themselves.

Mixed Technology Assembly

Mixed technology assembly combines surface mount and through hole components on the same board, so the build process includes multiple assembly stages. Automated placement handles surface mount parts first, followed by manual or wave soldering for through hole components, which extends overall assembly time.

Switching between processes adds handling, inspection, and scheduling steps. Each transition requires checks to confirm alignment, solder quality, and component integrity before the build can move forward, and that extra coordination increases labour input.

From an assembly cost perspective, mixed builds suit designs that need both compact layouts and mechanical strength. The trade off is additional time on the line, and assembly pricing reflects that added complexity rather than any single process step.

Additional Services That Add to the Overall Cost

Design for Manufacture (DFM) Reviews

A Design for Manufacture (DFM) review focuses on whether a board can be assembled efficiently and consistently, so it plays a practical role in controlling assembly cost. During this review, the assembler checks component spacing, footprint accuracy, polarity marking, and placement access before the build begins.

Issues found at this stage are quicker and cheaper to correct than problems discovered during assembly. Adjusting pad sizes, improving access for inspection, or resolving clearance issues reduces the risk of slowed placement, rework, or build interruption later in the process.

From an assembly point of view, a DFM review does not add cost without return. It reduces unplanned labour during the build and helps the assembly process run as intended, which keeps pricing and schedules aligned with the original quote.

Quality Testing and Inspection

Quality testing and inspection add time to the assembly process, so they have a clear impact on overall PCB assembly cost. These steps exist to confirm that components are placed correctly and soldered to specification before boards move further downstream.

Automated Optical Inspection (AOI) checks component presence, alignment, and solder joints at speed, which helps catch placement issues early in the build. X-ray inspection supports assemblies with hidden joints, such as ball grid array packages, where visual inspection alone cannot confirm solder quality.

Functional testing verifies that the assembled board behaves as intended once powered. This stage takes additional time and setup, yet it reduces the risk of faults reaching later stages or finished products. From an assembly perspective, testing increases upfront cost, yet it lowers the likelihood of rework, delays, or scrap during production.

Cabling and Final Product Build

Some projects extend beyond PCB assembly and include cabling, enclosure fitting, or full product build, so these steps add labour time to the overall quote. When these tasks sit alongside assembly, they introduce additional handling, sequencing, and inspection stages that increase total build time.

Carrying out cabling and final assembly with the same supplier reduces handovers between stages. This approach simplifies scheduling, limits duplicate checks, and keeps responsibility for quality within a single process flow.

From a cost perspective, these services raise the total price through added labour rather than changes to the board itself. For teams managing complete products rather than standalone boards, combining assembly and final build can reduce coordination effort and make project timelines easier to manage.

How to Reduce PCB Assembly Costs Without Compromising Quality

Optimising PCB Design

Design decisions influence PCB assembly cost early, so small choices made during layout often have a measurable effect later on. Consistent track spacing and clear component access allow placement and inspection to run at normal speed, which keeps assembly time under control.

Tight spacing, unusual outlines, or unnecessary vias increase handling and inspection effort. Each of these adds time to the build, particularly when boards need repeat checks or slower placement to maintain accuracy.

Layer count and component density should reflect actual electrical and mechanical needs rather than worst case assumptions. Where designs allow, reducing unnecessary complexity shortens assembly time without affecting performance. Early discussion with the assembler often highlights layout details that slow the line, and addressing those points before release helps keep assembly pricing predictable.

Selecting Cost-Efficient Materials

Material selection affects PCB assembly cost through availability, handling, and process stability, so it needs to align with how the board will actually be used. Standard FR4 materials cover most applications and move through assembly without special process changes, which keeps both lead times and labour predictable.

Problems usually appear when materials are specified beyond what the application requires. Using higher-grade substrates than necessary increases material cost and can introduce longer lead times without improving assembly performance. On the other side, selecting a material that does not meet thermal or electrical demands can cause issues during soldering or testing, which adds rework and inspection time.

From an assembly point of view, cost-efficient material choice means matching the substrate to real operating conditions rather than assumed extremes. When material performance, availability, and assembly behaviour align, pricing stays stable and production moves without interruption.

Working with a Single Source Supplier

Working with a single supplier for PCB fabrication, assembly, and related services can simplify how a project moves from quote to build. When one team oversees the full process, information flows without repeated handovers, and questions are resolved without delay.

From an assembly cost perspective, this reduces duplicated checks, repeated setup decisions, and misalignment between stages. Schedules remain easier to manage when material availability, build readiness, and testing requirements sit within the same planning window.

For projects that include flexible or rigid boards, assembly, and final build, a single source approach limits coordination overhead and helps pricing remain consistent from prototype through to production. For teams looking to reduce uncertainty during quoting and scheduling, this model often provides a clearer route through the build process.

Average Price Ranges for PCB Assembly

Prices often shift from project to project, and so it helps to treat these UK ranges as a gentle starting point rather than fixed totals. Engineers and procurement teams sometimes say they feel unsure at the early stage, yet a few ballpark figures can make planning feel a little more manageable.

In fact, once you see how complexity and quantity shape the numbers, PCB assembly cost UK patterns start to look fairly consistent across most suppliers.

Typical UK PCB Assembly Price Ranges

| PCB Type | Complexity | Typical Quantity | Estimated Cost Per Board (GBP) |

| Prototype, 2 layer, simpler build | Low | 1–10 | £60–£120 |

| Prototype, 4–6 layer, mid build | Medium | 1–10 | £120–£250 |

| Prototype, 6+ layer, dense build | High | 1–10 | £250–£500 |

| Production batch, 2 layer | Low | 100–500 | £18–£40 |

| Production batch, 4 layer | Medium | 100–500 | £40–£80 |

| Production batch, 6+ layer | High | 100–500 | £80–£160 |

These figures cover setup, assembly, and basic inspection, yet they leave out extended testing or added services that can shift the total slightly.

Prototype Price Expectations

Prototype builds usually carry a higher cost per board, so this stage often attracts closer scrutiny during budgeting. The reason lies in preparation rather than volume. Setup, programming, and initial checks take the same amount of time regardless of how many boards are built, and in prototype runs, that time is shared across only a small number of units.

Dense layouts, fine pitch components, or non-standard parts increase prototype costs further, since they slow placement and extend inspection. These factors affect prototypes more noticeably than production builds, where time spreads across higher quantities.

From an assembly perspective, prototype pricing reflects the work required to prepare and validate a design before scale. Prototypes exist to confirm layout, placement, and function, and the higher per board cost reflects that role rather than inefficiency in the assembly process.

Production Batch Price Expectations

Production runs usually show lower and more stable unit pricing once volumes increase, so this stage often feels easier to forecast than prototype work. Setup and programming time remain the same as earlier builds, yet that fixed effort spreads across many boards, which reduces the cost per unit.

Assembly lines operate more efficiently during production batches. Components load once, machines run for longer periods without interruption, and inspection follows a consistent rhythm. That efficiency lowers labour time per board and keeps pricing steady across the batch.

Variation still appears when designs are complex or components carry supply risk, yet the main drivers remain predictable. From an assembly point of view, production pricing reflects how smoothly a design moves through the line at scale, rather than changes in the process itself.

How to Get an Accurate PCB Assembly Quote

Information Required for Quoting

An accurate PCB assembly quote depends on how clearly the build can be defined at the start, so the information you share matters as much as the design itself. When details arrive in a complete package, assembly planning moves faster, and pricing reflects the real work involved rather than assumptions.

Assemblers need enough data to assess placement time, inspection requirements, and testing scope. Missing or unclear information usually leads to follow-up questions, revised pricing, or conservative estimates that inflate early quotes.

From an assembly perspective, clarity reduces risk. When files, quantities, and expectations are set out clearly, quotes align more closely with final costs, and project timelines remain easier to manage.

Information Required for Quoting

Providing the following details allows a quote to reflect the actual assembly work:

- Gerber files covering copper layers, solder mask, and silkscreen

- A complete bill of materials with preferred part numbers

- Pick and place files showing component locations and rotations

- Expected quantities for prototype or production builds

- Testing and inspection levels required

- Lead time expectations for delivery

Supplying this information at the outset limits rework during quoting and keeps pricing aligned with the assembly process from the first estimate.

Why Working with a UK Manufacturer Matters

Working with a UK-based manufacturer affects PCB assembly projects through communication, scheduling, and supply control rather than price alone. When design, quoting, and production teams operate in the same time zone, questions are resolved quickly and build decisions are made without delay.

Local manufacturing shortens delivery routes and reduces reliance on extended logistics chains. This limits exposure to customs delays, shipping disruption, and last-minute schedule changes, all of which can affect assembly planning and cost.

From an assembly and procurement perspective, a UK manufacturer, like us at Altimex, offers clearer visibility across materials, production progress, and testing stages. That visibility supports more accurate quoting, tighter scheduling, and smoother movement from prototype through to production.

If you want to discuss a project or request pricing, you can contact us to speak directly with the Altimex team.