Altimex delivers high-reliability printed circuit boards (PCBs) for automotive applications, meeting industry-grade certifications and providing end-to-end manufacturing solutions.

Automotive PCB Applications We Can Serve

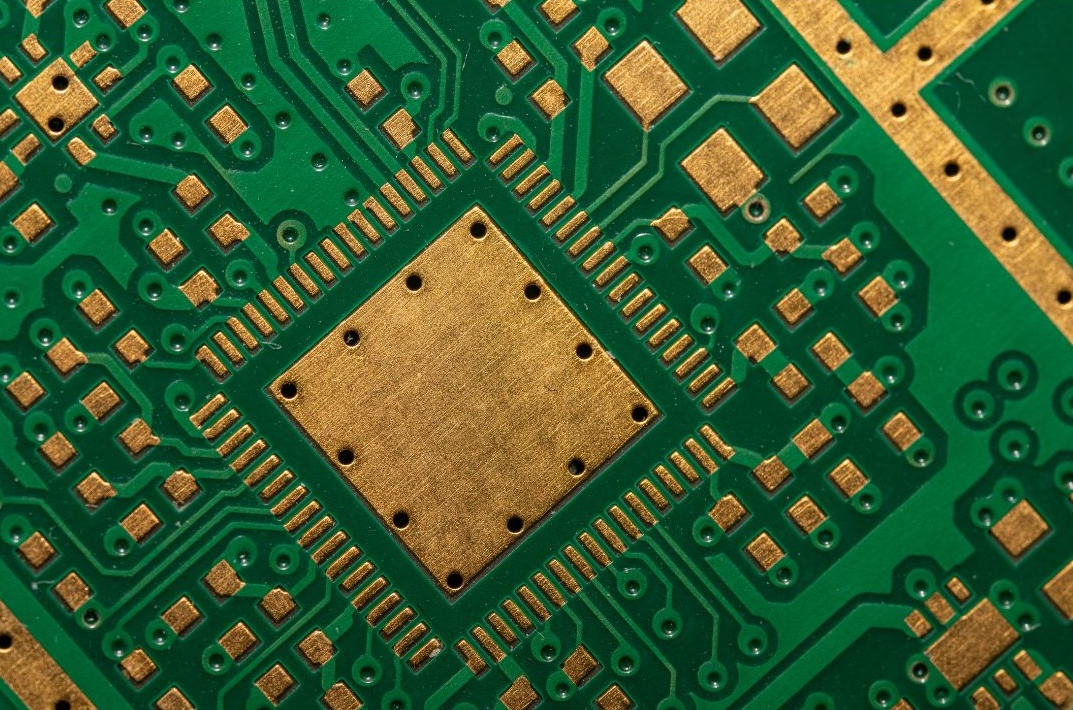

At Altimex, we manufacture high-reliability PCBs tailored for demanding automotive environments. Our engineering and production processes ensure dependable performance under extreme temperatures, vibrations, and harsh operating conditions.

From advanced driver-assistance systems (ADAS) to next-generation electric vehicles, we provide trusted circuit board solutions for:

Engine Control Units (ECUs)

Advanced Driver-Assistance Systems (ADAS)

Battery Management Systems (BMS)

Infotainment and Dashboard Electronics

Powertrain and Transmission Control

Vehicle-To-Everything Communication Modules

In-Vehicle Networking and Connectivity

Lighting and Climate Control Systems

Why Work With Altimex?

25+ Years Of Experience

Fast Turnaround Time

Tailored

Solutions

Building Long-Term Partnerships

Certified & Experienced Team

Types of PCBs We Can Manufacture for the Automotive Sector

At Altimex, we have the ability and expertise to manufacture a wide range of PCBs for automotive applications.

Flexible PCB

Designed for tight spaces and dynamic environments, flexible PCBs offer automotive systems enhanced durability, vibration resistance, and space-saving versatility. Ideal for dashboard assemblies, lighting systems, and moving components.

Custom PCB

Altimex develops bespoke PCBs to meet precise automotive specifications, ensuring optimal performance, long-term reliability, and compliance with automotive-grade standards.

Multilayer PCB

Ideal for complex automotive electronics, multilayer PCBs support high-density circuit design, EMI shielding, and superior signal integrity. Essential for ADAS, infotainment systems, and power management.

Double-Sided PCB

Offering increased circuit complexity in limited space, double-sided PCBs are perfect for automotive applications such as control modules, connectivity units, and vehicle communication interfaces.

Single-Sided PCB

Cost-effective and reliable, single-sided PCBs suit simpler automotive applications where performance and quality are still critical. Common uses include lighting controls, HVAC systems, and basic power distribution.

Interested In Automotive PCBs?

Get in touch with us and a member of our team will reach out to you.

Either use the contact form on our website or call us on +44 1829 741262

Why Are PCBs Important in the Automotive Sector?

Printed Circuit Boards (PCBs) play a crucial role in the automotive sector, powering everything from engine control units to infotainment, safety, and navigation systems. These boards must be extremely reliable, as they operate in harsh conditions including wide temperature ranges, constant vibration, and exposure to moisture and contaminants. That’s why precision and quality are critical in their design and manufacture.

A well-made PCB ensures that vehicle systems function safely, efficiently, and consistently. In short, without high-quality PCBs, modern automotive technology wouldn’t be possible.

Proud to have worked with

Bespoke Automotive PCB Capabilities

At Altimex, we understand that every automotive project is unique. That’s why we offer bespoke PCB solutions designed specifically to meet your requirements. From complex multilayer boards to flexible designs, we use advanced materials and precision manufacturing to ensure your PCBs perform reliably in demanding automotive environments.

Whether you need a prototype or a full production run, we work closely with you throughout the process to ensure your boards meet all industry standards and project specifications.

Get In Touch Today For Automotive PCBs

If you have a query about our services or feel like we could help you, please get in touch by filling the form out below or by calling us on 01829 741 262.

Frequently Asked Questions

Printed Circuit Boards (PCBs) are the backbone of automotive electronics, enabling reliable connections between various electronic components. They power and manage systems such as engine control units, infotainment, lighting, navigation, safety features, and driver assistance technologies. As vehicles become more advanced, especially with the rise of electric and autonomous vehicles, the demand for complex and high-performance PCBs continues to grow. These boards must perform reliably in harsh environments, making their quality and durability essential for both vehicle safety and performance.

Automotive PCBs operate in extreme conditions, exposed to heat, cold, vibration, moisture, and contaminants. Reliability is crucial because a failure in any electronic system can affect vehicle safety, performance, and regulatory compliance. For example, PCBs in braking or steering systems must function flawlessly at all times. Manufacturers must adhere to rigorous quality control processes and use materials rated for automotive use. Ensuring long-term reliability reduces warranty claims, enhances brand reputation, and ensures passenger safety, particularly in systems like ADAS or electric drivetrains.

Vehicles use a range of PCB types, depending on the application. Common examples include single-sided PCBs for simpler systems like lighting controls, double-sided PCBs for more complex components such as HVAC systems, and multilayer PCBs for advanced technologies like infotainment, navigation, and ADAS. Flexible PCBs are also used where space constraints or dynamic movement exist, such as in steering wheel controls or foldable displays. The type selected depends on the required complexity, space, performance, and environmental durability.

Automotive PCBs are specifically designed to endure harsh environmental conditions, including extreme temperatures, vibrations, and exposure to chemicals and moisture. They must comply with strict industry standards like IATF 16949 and ISO 26262. Materials used in automotive PCBs typically have higher thermal resistance and better mechanical strength. Moreover, automotive PCBs often undergo more rigorous testing, such as thermal cycling, humidity testing, and vibration analysis, to ensure they meet reliability and safety requirements throughout the vehicle’s lifespan.

Electric vehicles (EVs) require PCBs capable of handling higher voltages, increased thermal loads, and complex power management systems. As EVs rely heavily on electronics for propulsion, battery management, and charging, the demand for high-performance, heat-resistant multilayer PCBs has surged. These boards often need advanced materials, superior heat dissipation features, and robust EMI shielding. Designers must also consider compact layouts to save space in densely packed systems.

Multilayer PCBs are used in complex vehicle systems where high component density and signal integrity are critical. Common applications include infotainment systems, engine control modules, battery management systems, and ADAS (Advanced Driver-Assistance Systems). Their layered structure allows for compact design while maintaining electrical isolation between circuits, reducing interference. These boards are especially important in modern vehicles where space is limited and multiple functions need to be integrated into a single board. They also support high-speed communication between components and improved thermal management.

Flexible PCBs are ideal for areas where space is limited or where parts move frequently. In vehicles, they’re often found in steering wheel controls, airbag systems, lighting assemblies, and foldable infotainment screens. Their ability to bend and flex allows them to fit into curved or compact areas without sacrificing performance. Additionally, they help reduce weight and improve reliability by minimising the number of connectors and wires required. This makes flexible PCBs particularly valuable in electric and high-end vehicles, where compact design is a priority.

Vibration is a significant challenge for automotive PCBs, especially in engine compartments or suspension systems. Constant movement can lead to component fatigue, solder joint failures, and delamination over time. To mitigate this, automotive PCBs use vibration-resistant materials and reinforced mounting methods. Designers may also apply conformal coatings or potting compounds for added protection.

Rigorous testing, including vibration and shock simulation, is standard in the development process to ensure that the PCB can maintain functionality and reliability under prolonged stress.

Automotive PCBs often use materials with high thermal stability and mechanical strength. Common substrates include FR-4 (flame-retardant epoxy laminate), polyimide for flexible PCBs, and ceramic for high-power applications. Copper is typically used for conductive traces due to its excellent electrical conductivity. Surface finishes like ENIG (Electroless Nickel Immersion Gold) or OSP (Organic Solderability Preservative) are applied to improve solderability and durability. Material choice depends on the operating environment and the specific performance requirements of the system.

Automotive PCBs undergo extensive testing to ensure reliability and safety. Common tests include thermal cycling, vibration and shock testing, humidity resistance, and electrical integrity checks such as ICT (In-Circuit Testing) and functional testing. Visual inspections and automated optical inspections (AOI) are also used to catch defects. Some boards may be X-rayed to inspect internal layers. Compliance with industry standards ensures that only high-quality PCBs make it into vehicles, reducing the risk of failure in critical systems.