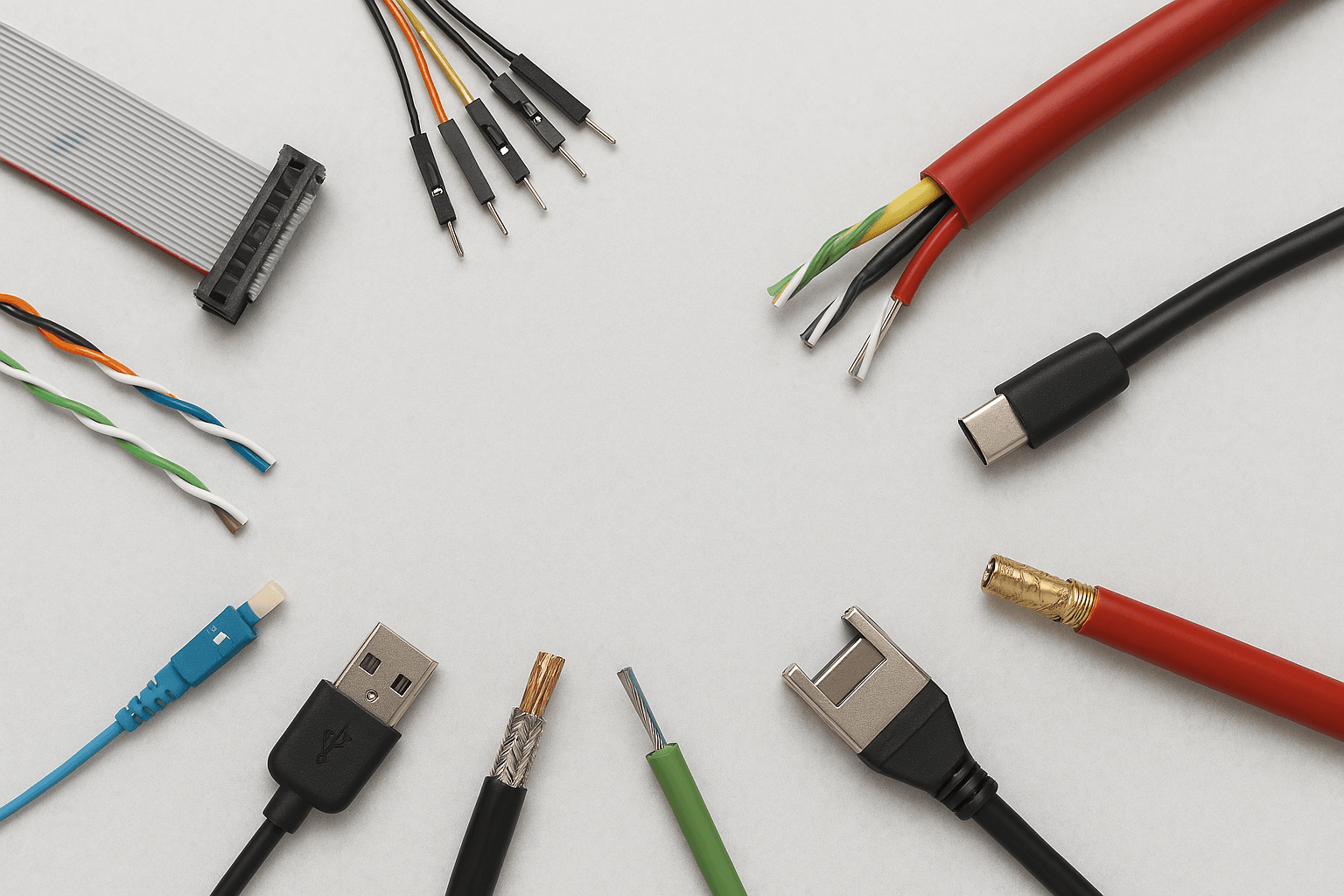

Picking the right cable might seem like a detail, but it often has a knock-on effect on how smoothly systems run, how safe they are, and how long they last. From data signals to electrical power to industrial cables, different setups need different specs.

And it’s not just about what a cable carries – it’s about where it’s going, how flexible it needs to be, and whether it’ll stand up to heat, movement, or interference.

In this article, we’ll unpack 10 types of cable – what makes each one tick, where they’re used, and why size plays such a big part.

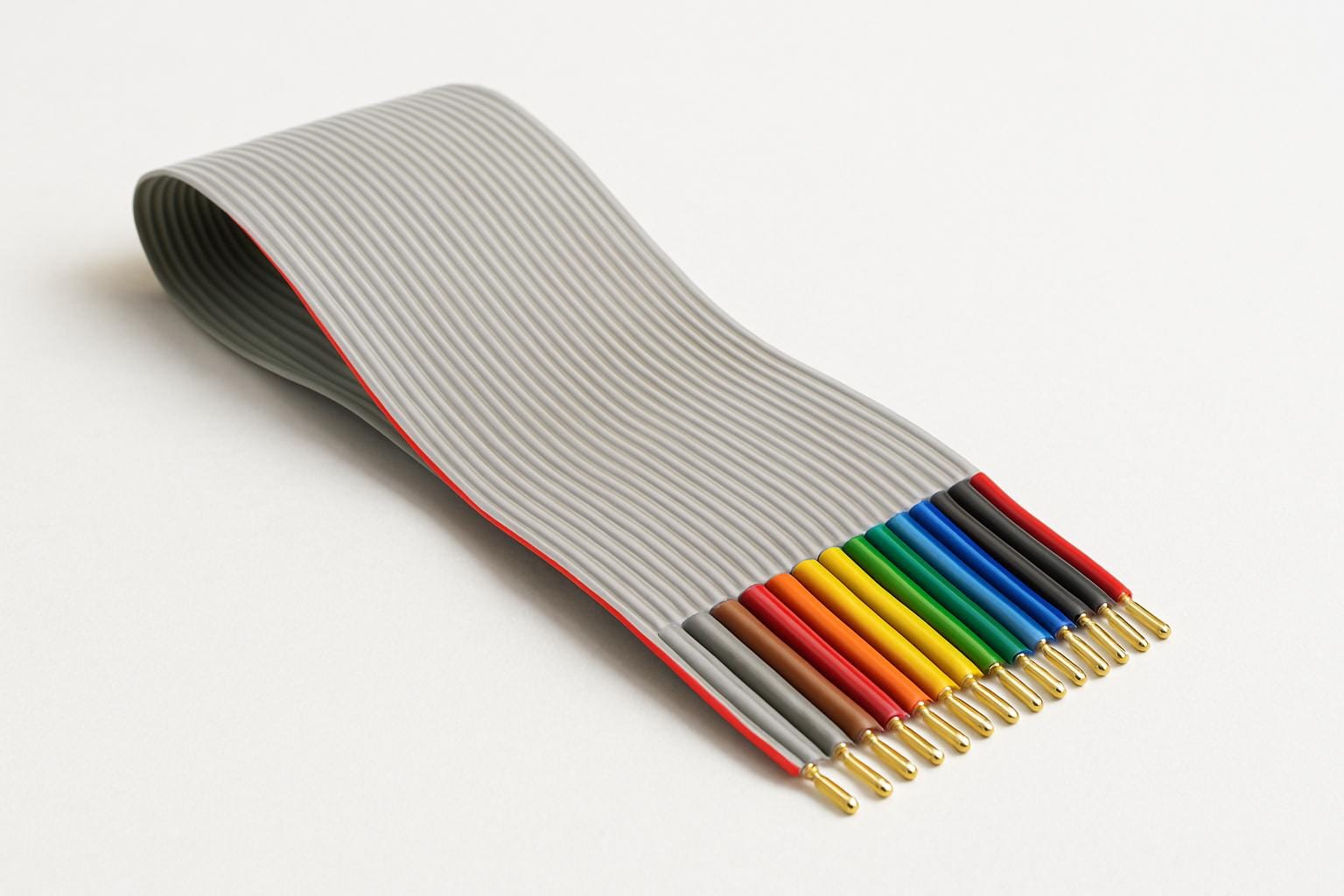

1. Ribbon Cable (Flat Cable)

Ribbon cables are flat, wide strips made from multiple parallel wires – ideal for tight, compact spaces. Their flexible shape and colour-coded wires make them easy to install and troubleshoot.

You’ll often see them in:

- Internal computer components

- Control panels

- Test equipment

They’re a neat solution for handling multiple connections at once without the mess of round cables – simple, efficient, and reliable for signal transmission in confined assemblies.

2. Flexible Flat Cable (FFC)

FFC looks a lot like ribbon cable at first glance – but there’s a subtle shift in design that makes a big difference. Instead of individual wires running side by side, FFC is made from flat metal conductors laminated between layers of flexible plastic film.

This structure gives it incredible bendability, so it’s a popular choice in tight, moving assemblies like foldable devices, cameras, or car infotainment systems.

Because it’s thinner and smoother, FFC often replaces bulkier cable options in electronics where every millimetre counts. It’s tidy, compact, and built for movement without damage.

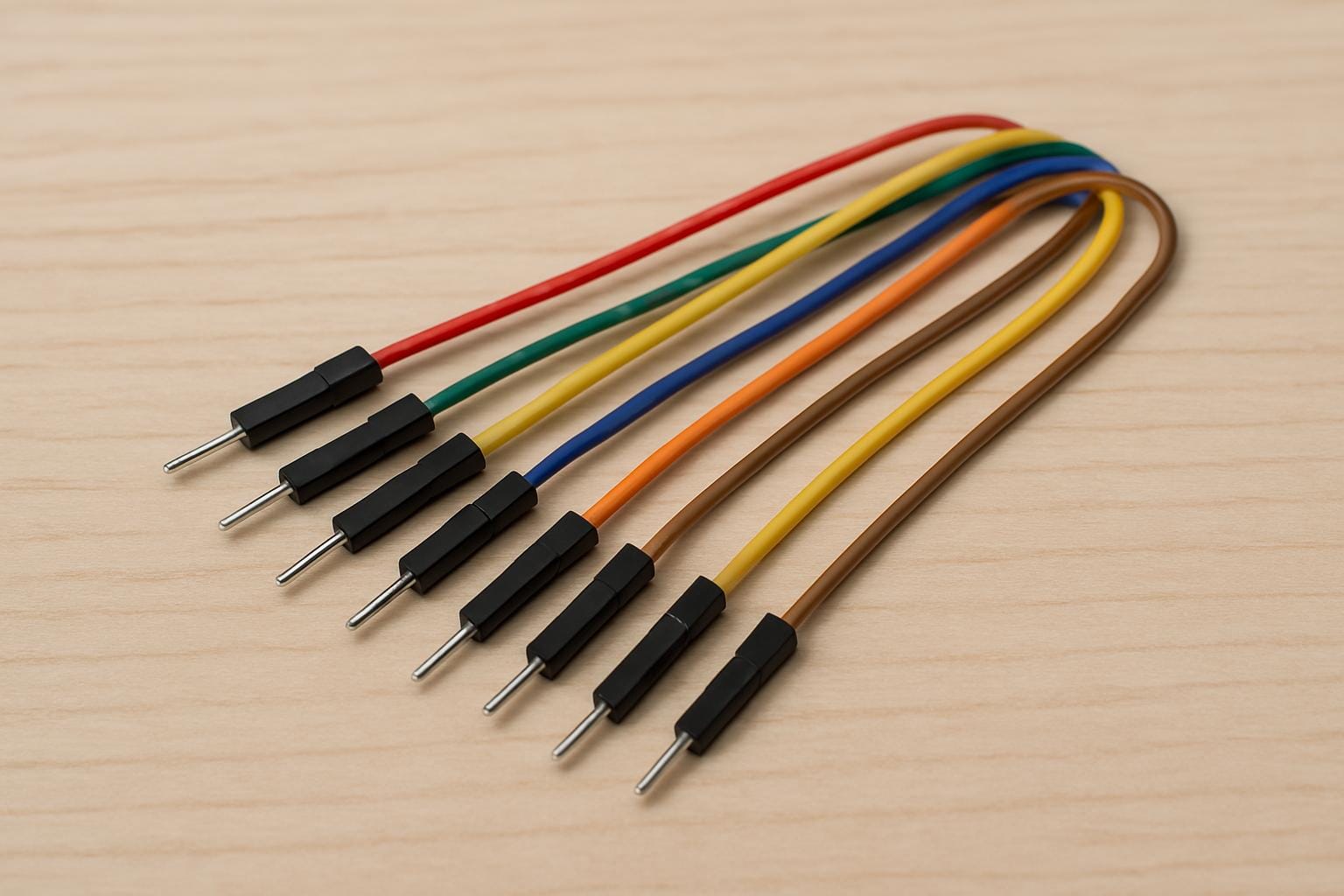

3. Jumper Wires

Jumper wires are the go-to for quick, flexible connections during testing and prototyping. You’ll spot them everywhere on breadboards and test circuits – helping engineers link up components without needing solder.

These wires usually come pre-fitted with pin or socket connectors, making them super convenient to use and swap around. They’re available in a range of wire gauges – from thinner 28 AWG to chunkier 22 AWG – depending on the current or signal needs.

In short, they’re not permanent, but they’re essential for figuring things out before things get finalised.

4. Coaxial Cable

Coaxial cable – often just called “coax” – has been around for decades, and there’s a good reason it’s still going strong. Built with a central conductor, an insulating layer, a metal shield, and an outer casing, it’s all about protecting signals from interference.

That shielding means coax handles high-frequency signals with less noise, which is why it’s used in:

- Broadband internet

- CCTV systems

- Radio transmitters

- TV aerials

Its structure helps it stay stable over long distances – something twisted pair cables don’t always manage as well. So, when signal clarity matters, coaxial often wins out.

5. Twisted Pair Cable

Twisted pair cables help reduce interference by – you guessed it – twisting the wires together. This simple design helps signals stay cleaner over short distances.

They’re everywhere in telecoms and networking, like:

- Ethernet (Cat5e, Cat6)

- Phone lines

- Audio setups

They’re cheaper and easier to install than coax, though they don’t offer the same shielding. Still, for many data and voice applications, twisted pair is more than capable – especially where budget and simplicity matter.

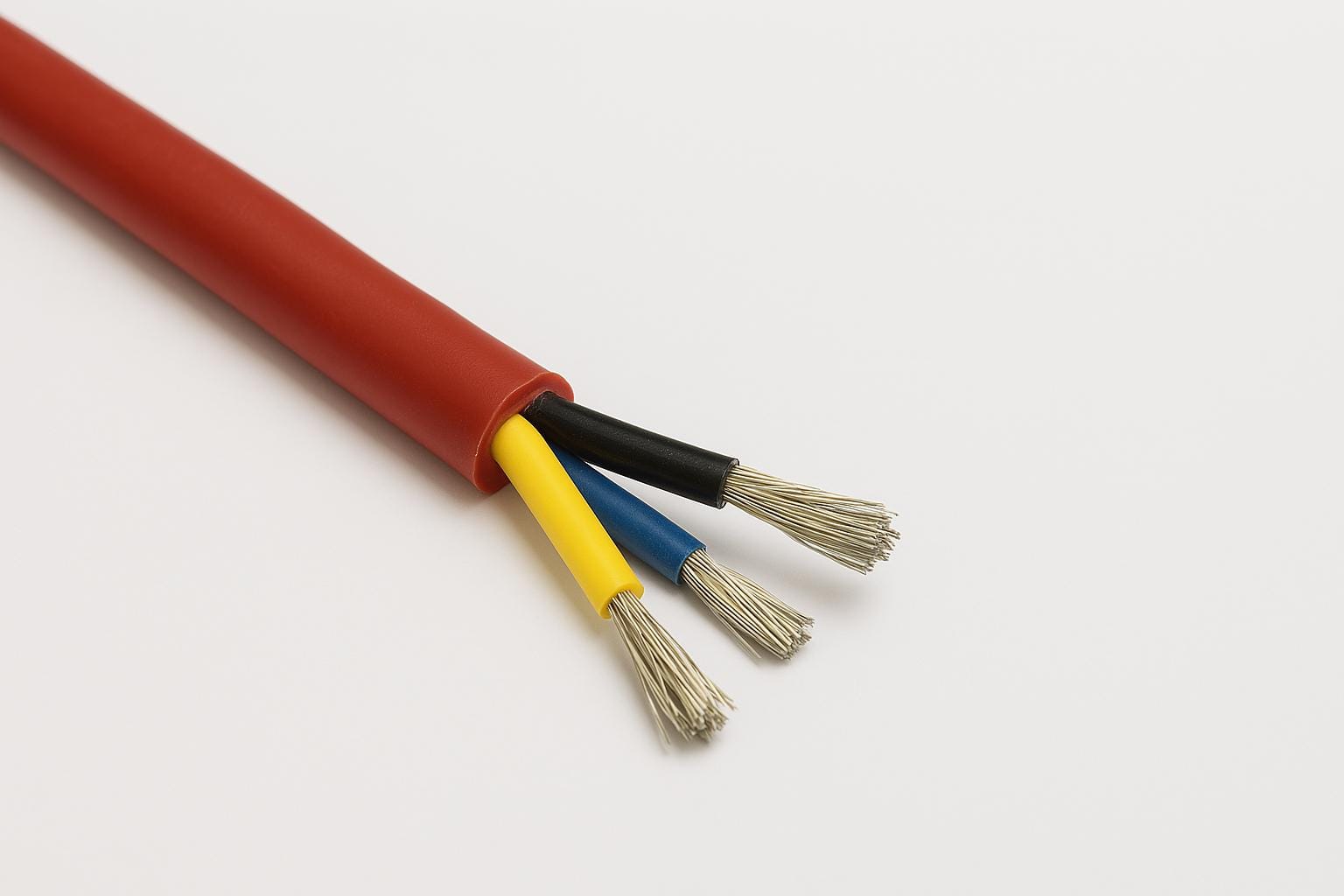

6. Power Cable (3-conductor)

Three-conductor power cables are what most people picture when thinking of a standard electrical cable – one for live, one for neutral, and one for earth. That extra grounding wire plays a big part in making systems safer and preventing shock.

You’ll spot these cables in everything from household plugs to industrial machinery. The insulation varies based on the setting – tougher outer jackets for factories, more flexible ones for portable equipment.

Power cable specifications tend to focus on current capacity, voltage rating, and insulation type – all necessary when it’s carrying the load.

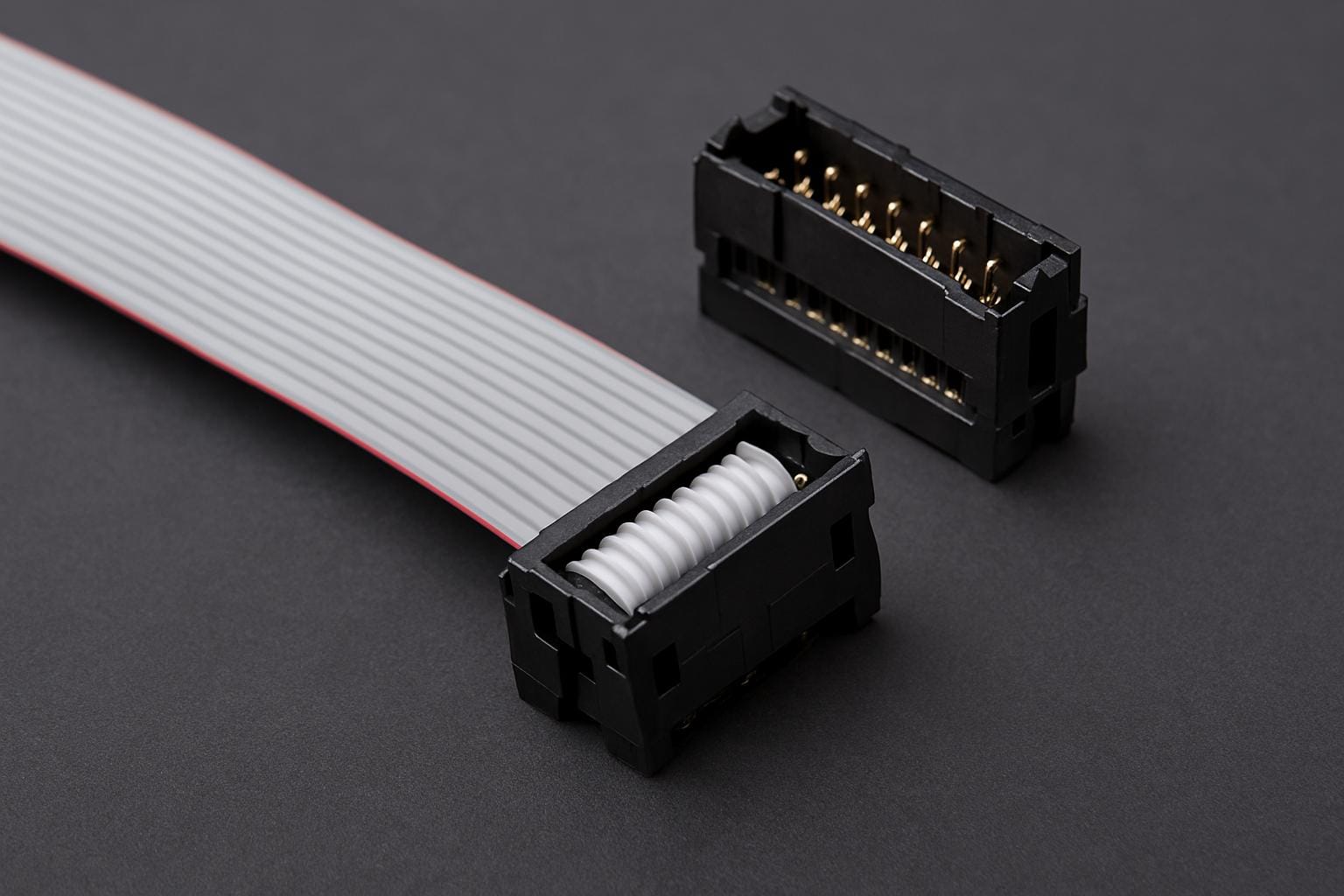

7. IDC Cable (Insulation Displacement Connector)

IDC cables aren’t really a cable type on their own – they’re more about how the connection is made. Instead of stripping wires and fiddling with solder, IDC connectors punch straight through the cable insulation to make contact with the conductor.

They’re often used with ribbon cables, especially inside control panels and computing hardware, because they save time and keep connections consistent.

The main upside? Quick assembly without sacrificing reliability, which is handy when you’re wiring up dozens (or hundreds) of connections in one go.

8. Servo Cable

Servo cables are built for motion – literally. They’re used to connect servo motors in automation setups, CNC machines, and robotics, where constant movement is part of the job.

These cables are specially designed to handle repeated bending, vibration, and flex without wearing out. You’ll often find a combination of power and signal wires inside, shielded to reduce noise between motor control and feedback systems.

Durability and flexibility matter more here than anything else – if a servo cable fails mid-operation, it’s not just an annoyance, it can bring an entire process to a halt.

9. Silicone Rubber Cable

Silicone rubber cables are built to take the heat – quite literally. They’re known for their ability to handle extreme temperatures without cracking, melting, or losing flexibility.

Used in places like steelworks, ovens, or high-temperature test environments, they keep working where most cables would give up. Their insulation stays pliable even in freezing conditions, too, making them a good fit for both ends of the temperature spectrum.

They’re often chosen not just for performance, but for safety, especially where thermal resistance is non-negotiable.

10. Micro Coaxial Cable

Micro coaxial cables pack the same structure as regular coax – just in a much smaller package. They’ve become the go-to for devices where space is tight but signal quality can’t take a hit.

Think medical imaging tools, smartphones, or inspection cameras – where flexibility and miniaturisation matter just as much as performance. Despite their size, they still manage solid shielding and high-frequency signal handling.

These cables are usually part of assemblies where precision is key and any electrical noise could throw things off. Tiny, tidy, and surprisingly tough.

Cables might not grab attention, but they quietly hold everything together. The type and size you choose affect safety, efficiency, and long-term performance.

From signal clarity to durability under stress, every detail matters more than you’d think. That’s why having the right cable for the job can save time, money, and hassle, and hopefully this electrical cable guide has helped you along the way.

Altimex offers a wide selection of high-performance cables to match whatever spec you’re working with. Need help finding the right fit? Contact us – we’re here to make things easier.