You may be tempted to use fibre optic cables within your business, but you still have some questions. So we have created this blog, answering the questions that get so often asked regarding fibre optic cables.

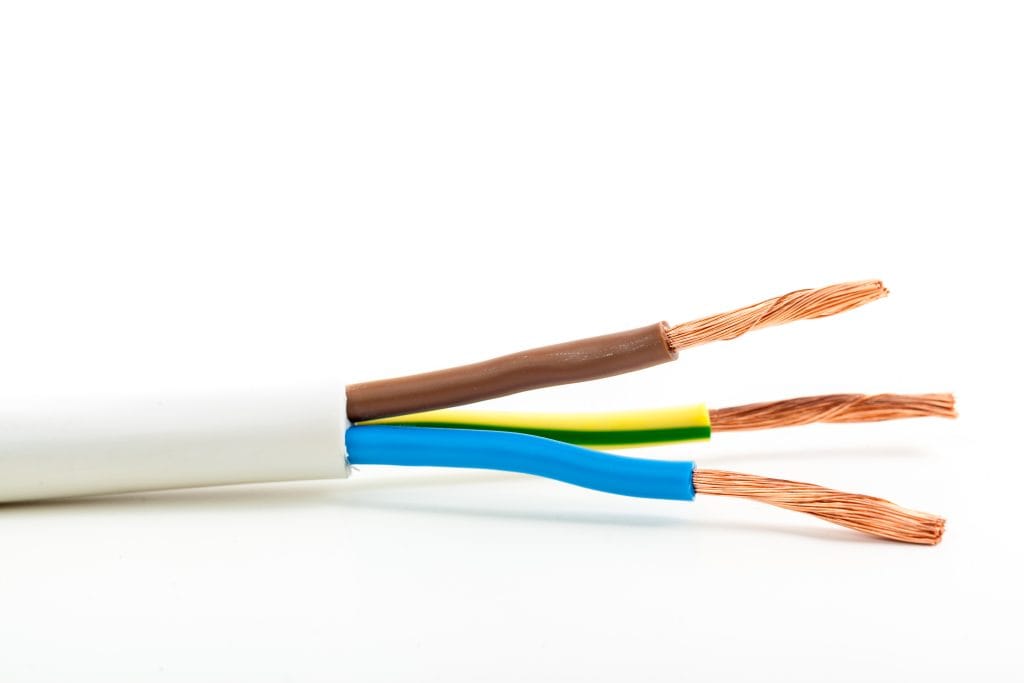

There are many benefits of using fibre optic cables, such as storing significant information and delivering it quickly over long distances. Because of these benefits, fibre optic cables haven’t entirely replaced copper cables, as they are used widely across many industries.

Continue reading to discover more about fibre optic cables so that you can make an informed decision before you buy.

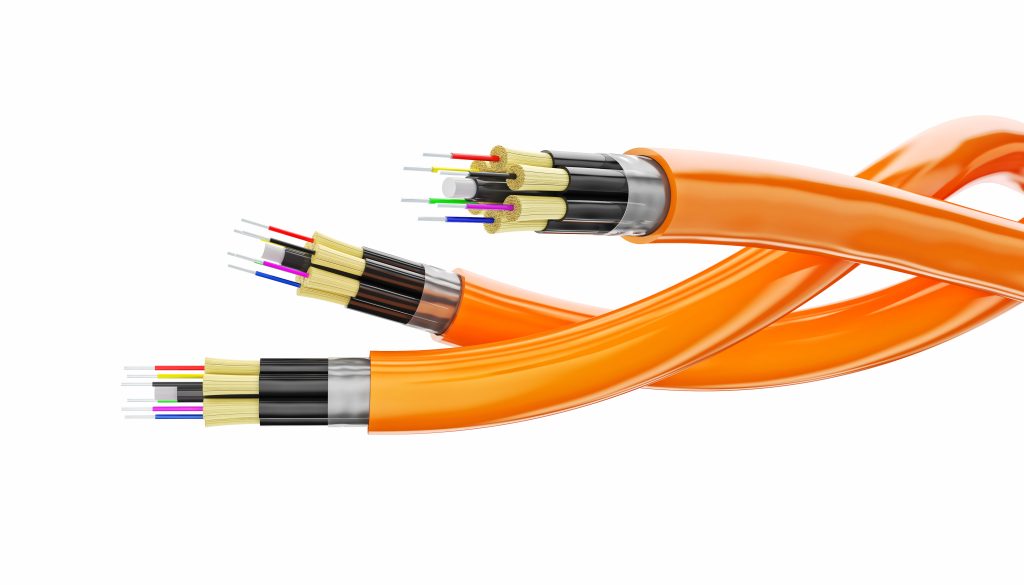

1) What are fibre optic cables made of?

Usually made of a transparent insulating material, fibre optic cables consist of thin glass fibre strands. These fibres are smaller than human hair strands and consist of three major components. These are the core, cladding, and coating.

Core

The core is the centre of each glass fibre and carries the light pulses that contain data.

To minimise light loss and data corruption, the core features pure, clear glass, enabling a consistent light signal to travel from end to end.

Cladding

Designed to confine light to the core, the cladding has to comprise a material with a low refractive index to enable light to reflect, keeping it inside the core to pass through the fibres.

The cladding surrounds the core; without it, the core has less protection and any outside light may interfere with the cable’s function, i.e. the light signal within the fibre may be lost.

Coating

The outside of the fibre optic, usually made up of plastic or rubber, is called the coating. This protects the fibres from environmental elements, enabling better performance and reducing the likelihood of hazards.

Fibre optic cables have revolutionised telecommunication businesses, such as those that offer internet and television services.

This type of cable has a high carrying capacity and a higher bandwidth than copper cables allow, which is why they are used by many industries where data needs to be transmitted at high speed and over long distances.

2) Does fibre optic internet require a phone line?

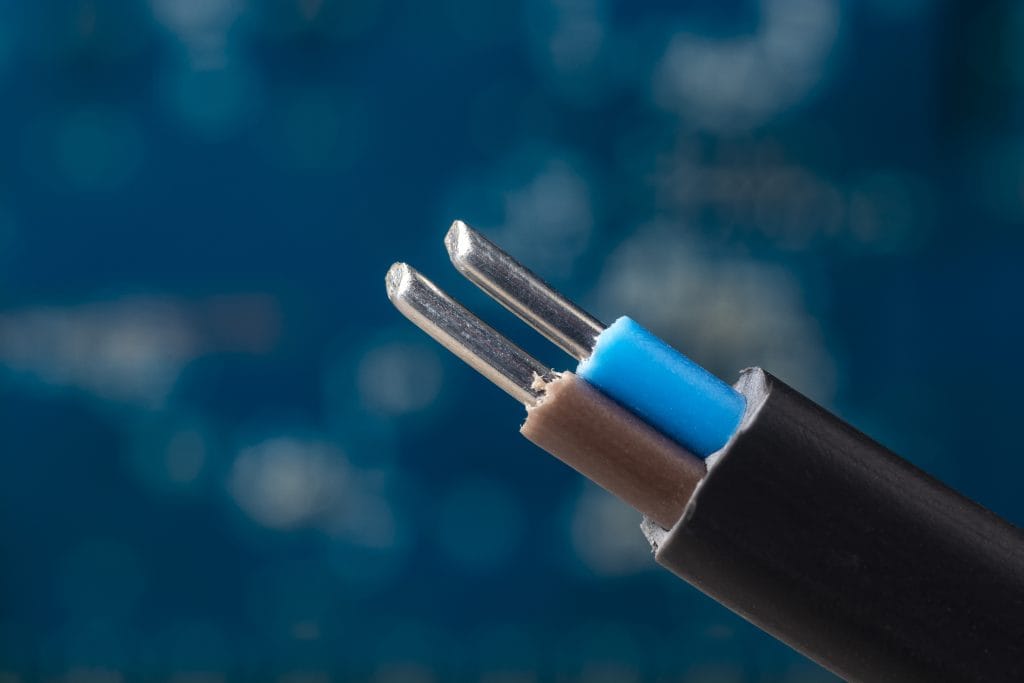

Fibre broadband does not need a phone line; it requires cable made from glass or plastic and is part of a network that is separate from phones.

However, most of the UK receives their internet through FTTC (Fibre-To-The-Cabinet), and if this is the case, you will require copper telephone cables.

3) Can fibre optic cables be repaired?

Yes, fibre optic cables can be repaired by a method that is called splicing.

An optic fibre cable may need repair if they have snapped or there is connector damage due to excessive force during installation.

Fibre optic cables can be repaired via two splicing methods:

Mechanical Splicing

This is the process of aligning optical fibres via a self-contained assembly.

In mechanical splicing, the fibre ends are held together with their cores aligned to allow light to pass through. A trained professional with specific expensive equipment is required to carry this out.

It is worth noting that the fibres are not permanently attached during mechanical splicing.

Fusion Splicing

This is the process of welding optical fibres together.

Fusion splicing is the most commonly used method of splicing for many reasons, such as:

- There is less light lost because it allows for a continuous connection.

- It provides a stronger and more dependable joint, making it a more permanent solution.

Overall, the above benefits of fusion splicing enable better protection compared to mechanical splicing. With fusion splicing, there are fewer failures and higher performance levels.

4) How is fibre broadband installed?

The method by which fibre broadband is installed depends on the broadband supplier.

However, the usual process is as follows:

- The engineer will drill a hole, usually close to your front door, outside your home. This hole is typically around 1cm in diameter.

- They will run a fibre cable from this access point.

- Next, they will install a fibre socket inside your home. This is where both your fibre cable and wifi router will plug into.

- Lastly, they will test that the connection is working correctly.

The whole installation process typically takes around an hour.

5) How can I tell if fibre is multimode or single-mode?

There are various ways to identify whether a fibre optic cable is single-mode or multimode. But first, what is the difference between single-mode and multimode fibre optic cables?

Well, single-mode fibre (SMF) is designed to spread a single light mode. This means that light travels down a single path.

Multimode fibre (MMF) allows for multiple light modes. It essentially allows light to travel down several paths simultaneously.

Single-mode fibre has a better bandwidth compared to multimode fibre, so it can allow more traffic across more channels and over longer distances.

However, multimode fibre can reach distances needed by many businesses since it is cheaper than single-mode fibre, and it is a popular choice.

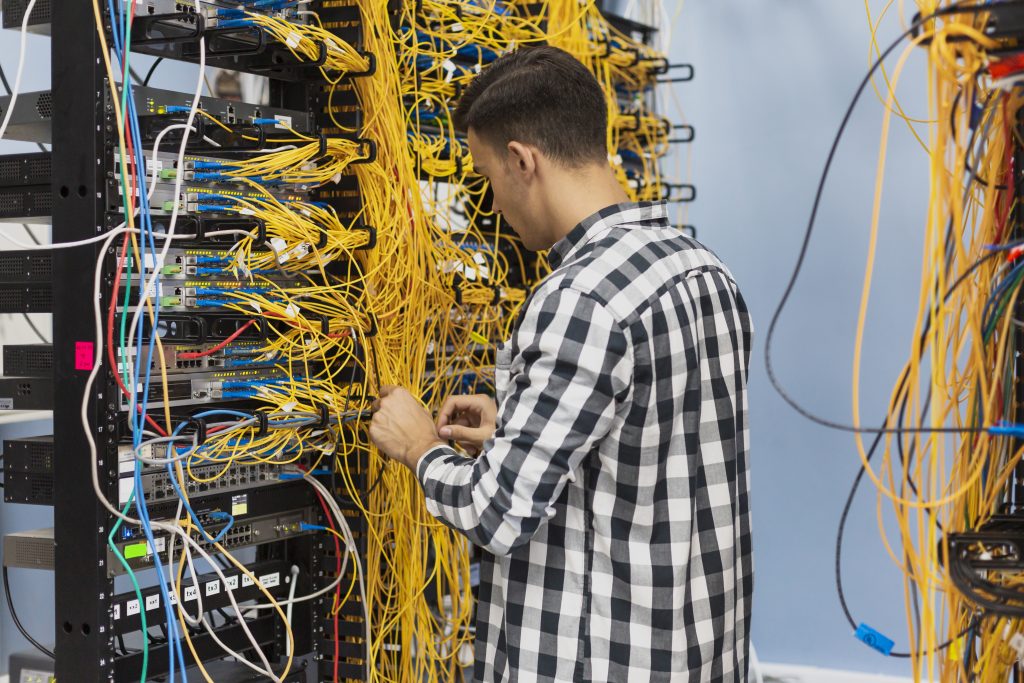

You can identify whether a fibre optic cable is single-mode or multimode by the colour of the fibre patch cords.

- For single-mode optical fibre cables, the patch cord is yellow.

- For multimode optical fibre cables, the patch cord is orange.

You can also ascertain whether a fibre optic cable is single-mode or multimode by the colour of the bale clasp (which enables the processing and distribution of data).

- For single-mode optical fibre cables, the bale clasp can be grey, purple, blue, green, yellow, orange, red, or brown.

- For multimode optical fibre cables, the bale clasp will be black.

Now that you understand more about fibre optic cables, you may be considering incorporating them within your business to speed up productivity. If so, contact us today to discuss our fibre optic services.