Printed Circuit Boards (PCBs) are a major part of modern electronics, forming the base of the many devices we rely on daily.

As industries continue to change, the need for custom PCBs has grown exponentially, catering to specific design and performance requirements that standard PCBs can’t meet.

Whether it’s telecommunications, medical devices, or consumer electronics, customised PCBs are now a major element in creating cutting-edge products.

In this article, we will look at the top 10 benefits of opting for a custom-made PCB, demonstrating how these specialised solutions enhance performance, reliability, and overall efficiency in various applications.

Companies across sectors are increasingly turning to custom PCBs, made possible through advanced PCB assembly, to stay ahead of the competition and meet their unique needs.

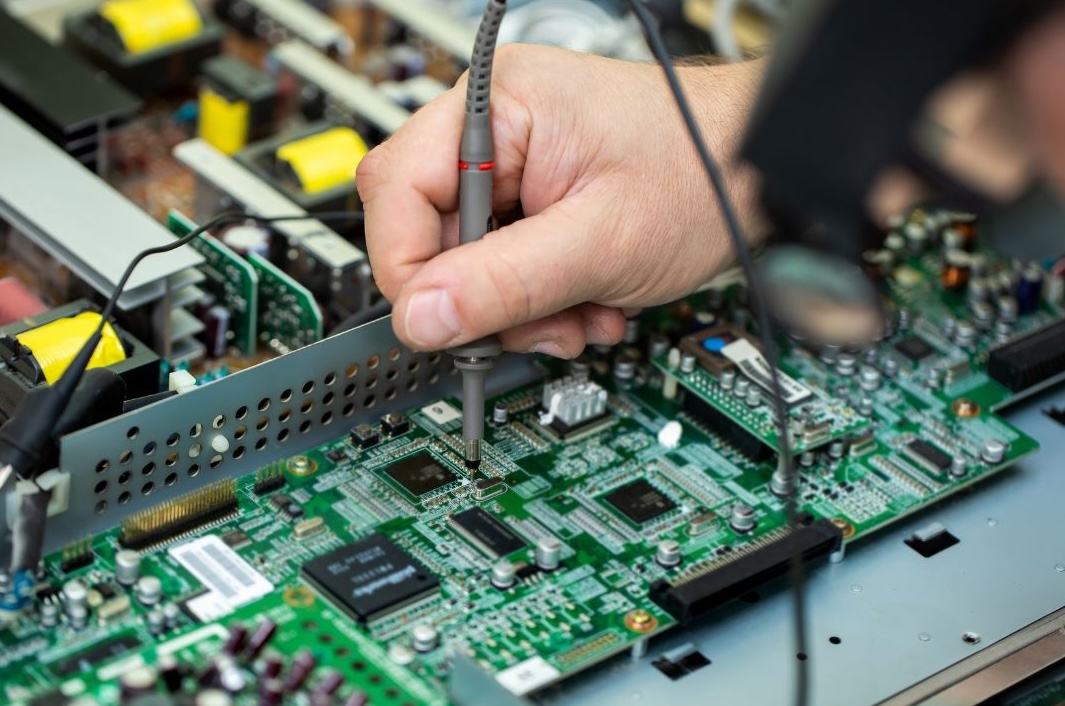

Improved Performance and Reliability

This specifically created PCB significantly improves performance and reliability by being specifically designed to meet precise requirements.

This provides improved signal integrity reduces the risk of errors or malfunctions and provides the ability to specify component placement to assist the electronic systems to function correctly. This is particularly useful in applications where long-term reliability is essential.

Incorporating specific materials and designs suited to the application, these PCBs offer reliability, allowing for consistent performance even in demanding environments.

This approach not only boosts the product’s overall quality but also contributes to increased customer satisfaction by meeting and exceeding performance expectations.

Customisation for Specific Needs

One of the primary benefits is their ability to meet unique specifications and requirements.

This makes sure that they are suited for specific use cases and environments.

By incorporating specialised components and materials, these offer flexibility in layout and design, allowing them to fit perfectly within particular products.

This means that each PCB can be designed to handle the unique challenges and demands of its intended application, resulting in a more efficient and effective electronic solution.

Reduced Size and Weight

Custom-made PCBs allow for compact designs suited to the dimensions of the product they will be used in.

By eliminating unnecessary components and using lightweight materials, these can significantly reduce the size and weight of the final product.

Additionally, they can integrate multiple functions into a single board, further streamlining the design and reducing bulk.

This reduction in size and weight is particularly beneficial for portable and wearable electronics, where space and weight are major considerations.

Cost Efficiency in Large Production

In large-scale production, these provide substantial cost efficiencies.

By capitalising on economies of scale, companies can reduce the cost per unit as production volumes increase.

For example, a telecommunications company producing thousands of units can significantly lower costs by standardising and optimising the PCB design for mass production.

Moreover, these PCBs reduce material wastage and streamline manufacturing processes, contributing to overall cost savings. The durability and reliability of these products also mean fewer replacements and repairs over time, resulting in long-term financial benefits.

Faster Prototyping and Production

They also enable faster prototyping and production, allowing companies to bring their products to market more quickly.

With speedy turnaround times from design to production, businesses can rapidly test and iterate their prototypes.

This efficient scaling from prototype to mass production is facilitated by advanced manufacturing techniques, which allow for high precision and quality.

The ability to quickly produce and test prototypes is invaluable for innovation, allowing companies to stay ahead of the competition and respond swiftly to market demands.

Better Heat Dissipation

Effective thermal management is crucial for the longevity and reliability of electronic components.

Custom-made PCBs can integrate advanced thermal management solutions that are specifically designed to handle the heat dissipation needs of a given application. For example, in high-performance computing systems, custom PCBs with built-in heat sinks and strategically placed components help prevent overheating and allow for stable operation.

By using heat-resistant materials and optimising the layout, these PCBs maintain the components within safe temperature ranges, reducing the risk of failure and extending the lifespan of the device.

Increased Design Flexibility

They also provide unmatched design flexibility, helping engineers to innovate and incorporate new technologies.

This flexibility allows for the modification and upgrading of designs to meet changing needs and emerging trends.

Custom features can be added to address specific requirements, making the final product more versatile and adaptable.

With the freedom to experiment and refine designs, engineers can create unique, high-performance solutions that stand out in the market.

Improved Aesthetics

A sleek, professional appearance is another advantage of these PCBs, and these boards offer custom branding along with labelling options, which provide neat and organised component placement.

Focussing on the specifics improves the product’s appeal and marketability, making it more attractive to customers and end-users.

Enhanced Durability

They are also designed with durability in mind, using robust materials to withstand harsh conditions.

Considerations for shock and vibration resistance provide long-lasting performance in demanding applications.

This durability translates to reduced maintenance and repair costs, offering a reliable solution for electronic systems.

Greater Control Over Quality

Strict quality assurance processes and detailed oversight of production stages allow for the enforcement of stringent quality standards.

This consistent production of high-quality boards ensures reliable performance and improves the overall value of the final product.

Custom PCBs offer numerous advantages, from improved performance and reliability to enhanced design flexibility and cost efficiency.

These tailored solutions address specific needs, reduce size and weight, and provide significant benefits in large-scale production.If you’re looking to improve your electronic products and ensure they meet the highest standards of quality and innovation, consider looking at custom-made PCBs. For more information and to discuss your specific requirements, contact us at Altimex – your trusted partner in custom PCB solutions.