When someone’s choosing between a BNC connector and an SMA connector, it usually means performance, reliability, or both are on the line. So, how do you decide which is the better fit? That, in some respects, depends heavily on the signal strength, size restrictions, and how rough the environment might get.

Both RF connectors fall into the coaxial connectors category, yet they behave quite differently in practice. From how they fasten to how high a frequency they can handle, the technical gap isn’t subtle, and that’s exactly what makes picking the right one so important.

This comparison breaks down where each shines (and where each might fall short), covering connector impedance, high-frequency connectors, and key connector applications. If you’re selecting components for our Interconnect cabling systems, this guide helps ensure the connector you pick does more than just fit – it performs.

Connector Type & Coupling Mechanism

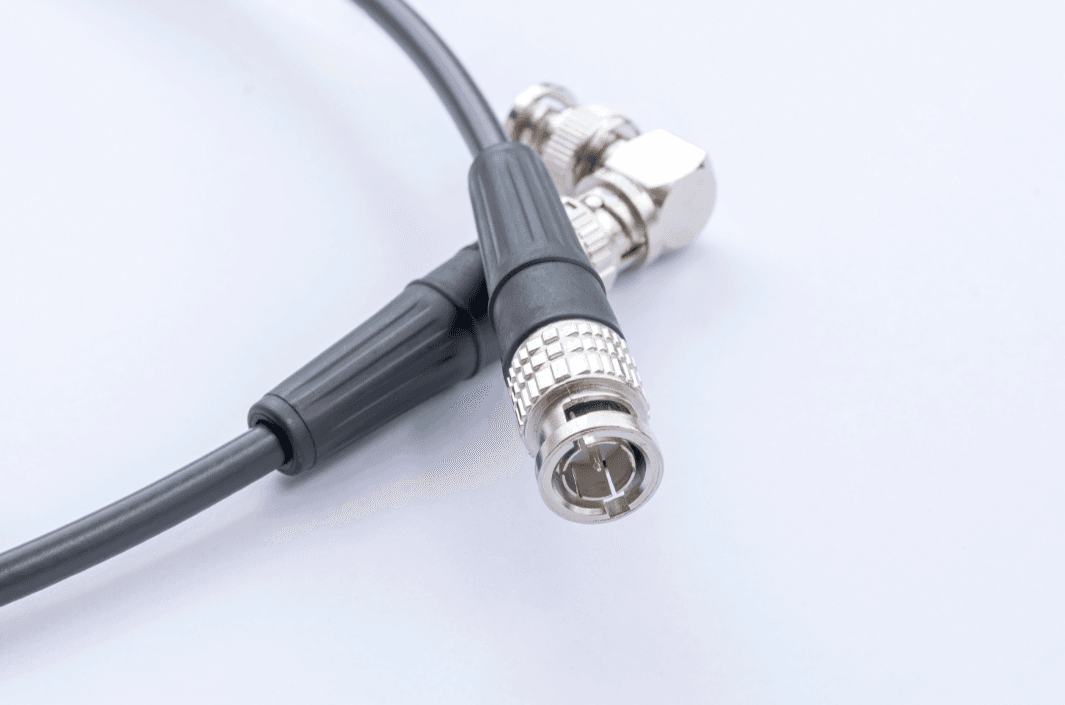

BNC Connectors – Quick-fit with bayonet coupling

The BNC connector uses a bayonet-style lock that twists into place without tools. It’s easy to use and ideal for setups needing frequent changes. The quick connection is handy, though it’s less secure in high-vibration environments. For lab tests and video feeds, it’s often the practical, no-fuss option.

SMA Connectors – Threaded precision for tighter conditions

The SMA connector, by contrast, relies on a threaded interface. It might take a bit longer to attach, but it creates a much tighter fit. This helps maintain consistent electrical contact in high-frequency setups. In fact, for many RF connectors dealing with delicate signals, this more secure grip often makes all the difference in performance.

Frequency Range

BNC – Built for lower-frequency tasks

The typical BNC connector handles frequencies up to around 4 GHz – and for a lot of video, test bench, and basic RF connector setups, that’s absolutely fine. It’s more or less the reliable choice for short-distance or lower-bandwidth needs. However, push it too far beyond that frequency ceiling and, frankly, signal integrity can start to slip – which is something no one wants mid-project.

SMA – High-frequency stability

In contrast, the SMA connector is designed to work well beyond that. Standard versions support frequencies up to 18 GHz – and some variants go even higher. This is where high-frequency connectors really earn their keep. The precision threading and tighter design reduce signal leakage, making the SMA type better suited to more sensitive or data-heavy tasks that can’t afford signal drop-offs.

Impedance

BNC – Versatile with two options

One of the quirks of the BNC connector is that it comes in both 50-ohm and 75-ohm versions. That sounds like a small detail, but the difference can seriously affect performance – especially in video and RF signal work. Get it wrong and you might run into reflections, signal loss, or unexpected distortion. So, choosing the right connector impedance for the job isn’t just helpful – it’s absolutely necessary.

SMA – Consistent 50-ohm performance

The SMA connector, on the other hand, sticks with a standard 50-ohm impedance. That makes it a more consistent performer in high-frequency RF applications. Less guesswork, fewer mismatches, and better signal control – especially when working with coaxial connectors in more technical setups.

Size & Compactness

BNC – Bigger, easier to handle

The BNC connector isn’t exactly subtle. Its larger size makes it easier to grip and connect, which is great during prototyping or lab work where speed matters more than squeezing into tight enclosures. For setups with room to spare, it’s a solid, fuss-free option.

SMA – Small footprint, serious performance

The SMA connector, in contrast, is much smaller – and that’s no accident. Designed with space constraints in mind, it tends to fit better into compact RF assemblies or high-density modules. If you’re working with miniaturised devices or tight board layouts, SMA often just makes more sense. It’s one of the reasons connector applications in aerospace, telecoms, or defence often favour this sleeker form.

Durability & Robustness

BNC – Fine for static setups

The BNC connector holds up well under typical handling – plug it in, unplug it, repeat as needed. That said, it’s not really built for rough movement or vibration-heavy environments. Over time, the bayonet connection can loosen slightly, especially if there’s any physical stress on the cable. So, in a more static setup, it works well – just don’t expect it to thrive on a vibrating rig or a mobile device.

SMA – Built for demanding environments

Now, the SMA connector? That’s a different story. With its threaded design and tighter fit, it’s more stable and shock-resistant. It’s not just small – it’s solid. For environments where vibration, movement or temperature swings are common, RF connectors like SMA tend to be the go-to.

Typical Use Cases

BNC – Common in testing and video

The BNC connector shows up pretty much everywhere from oscilloscopes to CCTV systems. It’s well suited for lab setups, signal testing, and lower-frequency video feeds – places where ease of use trumps everything else. It’s also a staple in RF testing environments where the frequency isn’t too high and the setup needs quick changeovers.

SMA – Preferred for precision

On the flip side, the SMA connector dominates in applications that need accuracy over convenience. Think antenna systems, satellite comms, or high-frequency radio modules. Because they handle higher frequencies without signal loss, they’re a smart fit for microwave and telecoms gear. These high-frequency connectors often support connector applications where stability and compactness matter just as much as signal fidelity.

Cost

BNC – Budget-friendly and widely available

The BNC connector usually wins on price. It’s easier to manufacture, widely stocked, and often chosen for lower-spec projects where cost control matters more than frequency performance. For test environments or general RF use, it ticks a lot of boxes without draining the budget.

SMA – Pricier, with purpose

The SMA connector, on the other hand, tends to cost more. That’s partly down to its precision threading and tighter tolerances. But in many cases, that extra cost pays off – especially in high-performance coaxial connectors or specialised RF connectors where stability and signal clarity aren’t optional.

Picking between a BNC connector and an SMA connector comes down to more than just habit or price – it’s about what your setup actually demands. Need quick connections and lower frequencies? BNC likely fits the bill. Working with compact, high-performance gear? SMA probably makes more sense.

In any case, understanding your connector applications, connector impedance, and required frequency range makes it much easier to match the right fit – not just the familiar one. If you’d like help selecting components for your next project, feel free to contact us.