In the background of almost every modern device, there’s something small that keeps the connections reliable, and Molex connectors often play that role. These compact components don’t usually get much spotlight, yet they’re quietly vital in powering up everything from your laptop to industrial machinery.

Whether you’re a design engineer trying to hit a deadline or a procurement manager sourcing components that do what they promise, knowing what Molex connectors offer can save more than just time; it could mean the difference between stable operation and repeated faults.

Molex connectors have been a fixture in electronic manufacturing for decades, and their reputation is based on three things: reliability, flexibility, and design consistency. But which type do you need? How do you choose the right one for your build? What makes them a safe bet in demanding conditions?

We’re covering all of that here in this Molex connector guide — from types of Molex connectors to installation and troubleshooting tips. If precision matters to your project, you’re in the right place.

What Are Molex Connectors?

Before getting stuck into types and technical details, it helps to pin down what Molex connectors are and why they matter so much in electronic builds.

Definition and Purpose

Molex connectors are small but smart electrical connectors used to link wires to circuits or other wires. Simple, right? Well, sort of. They’re not just about physical connections but about keeping power and data flowing cleanly and consistently, even in harsh environments.

You’ll find them in places where reliability isn’t negotiable: automotive electronics, industrial control systems, lighting assemblies, telecom infrastructure, and more. They’re chosen because they cope well with vibration, fit snugly even in tight spaces, and stay put once installed. For engineers and manufacturers, Molex isn’t just a brand, it’s shorthand for a safer, cleaner connection.

These connectors usually come as modular systems, offering a mix-and-match of housings, terminals, and mounting styles. That flexibility makes them a practical choice when precision matters and failure isn’t an option.

History of Molex Connectors

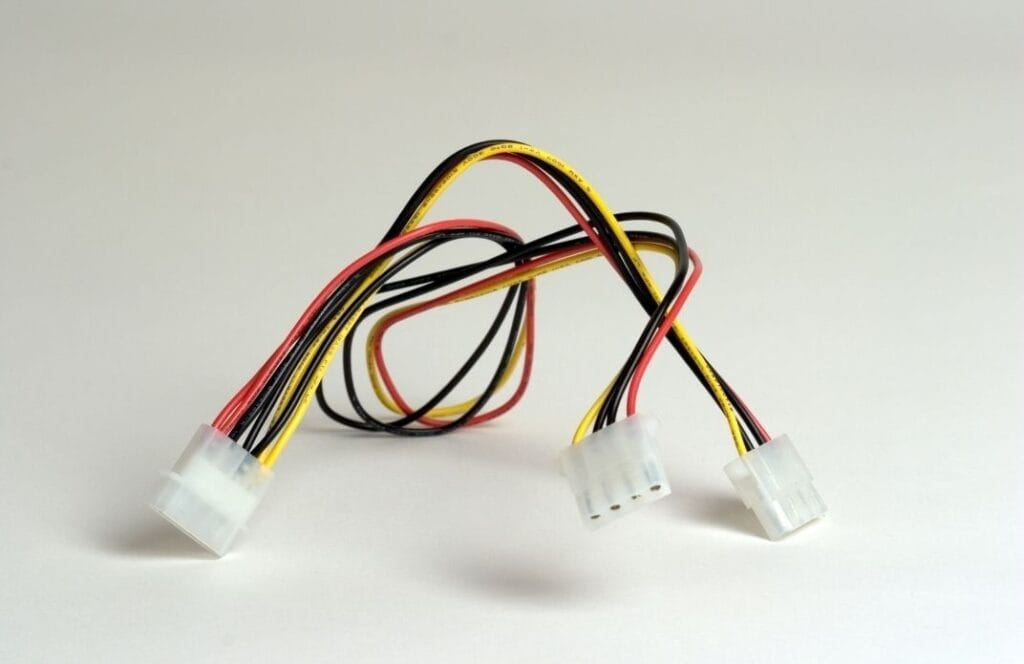

Back in 1938, Molex started out making plastic products, including flowerpots. It wasn’t until the mid-20th century that they moved into the electrical connector space, and that’s when things took off. Their breakthrough came with the invention of the Molex 4-pin connector, which became a staple in early computer power supplies.

Over the years, Molex connectors evolved alongside electronic manufacturing itself. New materials, smaller footprints, better locking mechanisms, it’s all developed in response to engineers needing stronger performance in smaller spaces.

Now, the Molex name is practically built into the DNA of electronic design. They’re not just another part on a spec sheet; they’re a baseline for connection quality.

Types of Molex Connectors

Choosing the right connector starts with knowing what’s out there. Molex doesn’t just offer one kind of solution; its range covers everything from basic wire-to-wire links to compact board-mounted options that squeeze into tight assemblies.

Here’s a breakdown of the most common types of Molex connectors and where each tends to be used.

Wire-to-Wire Connectors

These are made to link two wires directly without going through a circuit board. They’re often used in harness assemblies, automotive wiring, and field installations where flexibility matters.

Common examples:

- MLX Series: Handles moderate current and voltage, with good locking strength.

- Mini-Fit Jr.™ Series: Known for compact design with high power handling.

- Standard .093″ Series: Larger, sturdy, and great for rugged connections.

Wire-to-Board Connectors

This type connects wires directly to a printed circuit board (PCB), which helps save space and reduce weight, useful in anything from lighting systems to control panels.

Common examples:

- KK® Series: Used in low-current applications where space is limited.

- Micro-Fit 3.0™: Balances size with performance, often seen in consumer tech.

- Nano-Fit™: Ultra-small, often selected where precision is key and space is tight.

Board-to-Board Connectors

Ideal for connecting one PCB to another, these are essential in modular systems and multi-layered hardware. They’re usually low-profile, with tight tolerances and strong signal reliability.

Common examples:

- SlimStack™ Series: Compact, high-density connections for data-heavy boards.

- Mezzanine Connectors: Offer parallel board stacking with consistent spacing.

- Backplane Connectors: Built for high-speed signals in server or telecom equipment.

Other Specialised Connectors

Beyond the core types, Molex produces a wide range of niche connectors to meet very specific needs like waterproofing, high-speed data transfer, or extreme temperature tolerance.

Specialised types include:

- Sealed Connectors (e.g. ValuSeal™): For outdoor or high-moisture environments.

- FFC/FPC Connectors: For flat flex cable connections in tight electronics.

- RF Connectors: Built for radio frequency and wireless data systems.

Each of these types solves a different problem, whether it’s reducing assembly time, dealing with vibration, or saving space. Knowing the types of Molex connectors available helps you avoid costly mismatches before you even place your order.

Key Features and Benefits of Molex Connectors

So, why do engineers tend to trust Molex over other connector brands? Well, it’s not just brand familiarity, it’s the mix of build quality, consistent performance, and ease of design integration that makes a real difference.

Durability and Reliability

These connectors aren’t just made to fit, they’re built to last. Molex designs tend to be rated for thousands of mating cycles, with contact materials that resist corrosion and wear. If your application involves regular disconnection, vibration, or exposure to heat, Molex products often hold up where others might fall short.

In critical industries like automotive or telecoms, where connection failure could cause serious downtime, that level of trust is more than just helpful; it’s expected.

Variety and Customisation Options

From compact 1 mm pitches to heavy-duty power connectors, Molex offers solutions for more or less every configuration you can think of. That variety makes them easy to integrate into both new product designs and legacy systems.

Some series also allow custom configurations, tailored pin counts, colours, and locking mechanisms, which help reduce assembly errors and improve cable management. It’s especially useful for manufacturers dealing with small-batch or specialist builds.

Ease of Use and Installation

You don’t want connectors that make assembly more complicated than it needs to be. Molex products typically use intuitive locking designs, clear markings, and user-friendly housing formats that make installation straightforward even when working in confined areas.

Toolless locking options, keyed designs to prevent misalignment, and crimping solutions that reduce strain on terminals are all part of why Molex connectors save time on the production line.

Quick Comparison Table

| Feature | What It Means | Where It Helps Most |

| High Cycle Durability | Lasts through repeated connections | Automotive, Telecom |

| Custom Pin Configs | Flexible layouts and locking options | Prototyping, OEM builds |

| Compact Sizing Options | Fits into tight or space-limited assemblies | Consumer electronics, LEDs |

| Secure Locking Systems | Prevents accidental disconnections | Industrial equipment, control panels |

These features aren’t just nice extras; they’re the reason Molex connector benefits consistently appeal to manufacturers that rely on precision and uptime.

Applications of Molex Connectors

Now that we’ve covered the types and features, let’s look at where these connectors actually show up. The range of Molex connector applications is surprisingly broad; they’re found in everything from consumer gadgets to heavy-duty machinery.

Consumer Electronics

Compact, low-profile, and consistent under repeated use, Molex connectors are widely used in modern devices and home technology.

Common uses:

- Laptop power and battery systems

- Mobile device charging circuits

- Smart home hubs and controls

- LED lighting modules

They’re a popular pick for consumer tech brands because they balance space-saving with reliability, a mix that isn’t easy to get right.

Automotive Industry

In vehicles, every connection has to survive heat, vibration, and long-term wear, and Molex delivers on all fronts. Their automotive-grade connectors support everything from infotainment to safety systems.

Common uses:

- Dashboard control panels

- Sensor arrays (e.g. ABS, lane detection)

- Battery management systems

- Headlight and taillight assemblies

With options for sealed enclosures and locking mechanisms, they help prevent costly connection failures down the line.

Industrial Equipment

For industrial environments, Molex offers connectors built to tolerate extreme temperatures, dust, and frequent mechanical stress.

Common uses:

- Robotics and conveyor systems

- Control panels for factory automation

- Power distribution within machinery

- Diagnostic and safety interfaces

These connectors help streamline complex builds, especially when downtime is expensive and difficult to recover from.

Telecommunications and Data

Signal clarity and density matter most here. Molex’s data-rated connectors often appear in high-speed and high-frequency systems.

Common uses:

- Server backplanes and data hubs

- Fibre optics interfaces

- Base stations and routers

- Signal repeater installations

They’re chosen for low-loss signal handling and consistent transmission, which is essential when speed and stability are on the line.

Each application area values different things, whether it’s size, strength, or speed, and Molex has earned its place by delivering across the board.

How to Choose the Right Molex Connector

Choosing the right connector might seem like a box-ticking task until the wrong choice causes issues later down the line. If you’re specifying components for a project where failure simply isn’t an option, it pays to spend a bit more time getting it right from the start.

Considerations for Voltage and Current

Different Molex connectors are rated for different electrical loads. Picking one that doesn’t suit the voltage or current in your system could lead to overheating or intermittent faults.

Double-check:

- Voltage rating (AC or DC)

- Maximum current per contact

- Contact resistance under load

For higher-power builds, like motor controllers or industrial drives, aim for connectors with reinforced insulation and larger contact areas.

Environmental Factors

Think about where the connector will be used. Moisture? Dust? Extreme temperatures? All of these could influence your decision.

Look out for:

- IP ratings for water and dust protection

- UV resistance (for outdoor use)

- Operating temperature range

Molex offers several sealed options for harsher environments, especially useful in automotive and outdoor installations.

Connector Size and Space Constraints

Not every build has room for bulky housings or thick wires. Molex makes connectors in a wide range of pitches and mounting formats, but knowing your space limits is half the battle.

Consider:

- Mounting orientation (vertical or right-angle)

- Pitch (distance between pins)

- Board footprint and clearance

Small-scale builds, like LED modules or wearable tech, often lean towards Micro-Fit or PicoBlade series.

Compliance and Standards

Meeting regulatory and industry-specific standards isn’t just about box-ticking; it’s about protecting the final product from avoidable legal or safety issues.

Check for:

- RoHS compliance

- UL certifications

- Automotive or medical-grade classifications

Quick Selection Checklist

- What’s the voltage and current your connector needs to handle?

- Will it face water, dust, vibration, or temperature extremes?

- How much space is available for installation?

- Are there compliance or certification requirements?

- Will it need to be disconnected often, or left untouched?

Getting these basics right upfront makes it easier to confidently choose a Molex connector that won’t need replacing down the line.

Installation and Maintenance Tips

Even the best connector can cause trouble if it’s installed badly or left to wear out unnoticed. Getting the most from Molex connectors often comes down to how they’re handled during setup and what’s done to keep them working over time.

Proper Installation Techniques

Installing Molex connectors doesn’t usually need specialist tools, but it does demand precision. Small misalignments or under-crimped terminals can cause serious headaches later.

Here’s how to keep things smooth from the start:

- Use the right crimping tool – Avoid generic tools; Molex offers calibrated crimpers that produce cleaner, more reliable joins.

- Check for pin alignment – Misaligned or bent pins are easy to miss and tricky to fix once the connector is mounted.

- Ensure full mating – Listen or feel for the click; partial connections are a common cause of signal failure.

- Label cables and connectors – This avoids confusion in larger assemblies, particularly when connectors are nearly identical.

Routine Maintenance Advice

Connectors don’t need constant attention, but periodic checks can prevent issues from building up unnoticed. This matters more in systems exposed to vibration, dust, or moisture.

Tips for long-term performance:

- Inspect connectors every 6–12 months – Look for wear, corrosion, or signs of overheating.

- Clean contacts with isopropyl alcohol – Avoid using water or generic cleaners that could leave residue.

- Replace cracked housings or bent pins – Don’t try to bend terminals back — they often weaken and break soon after.

- Secure loose cables – Movement over time can strain the terminals and cause micro-fractures.

Following these installation of Molex connectors tips can help extend their service life and prevent minor faults from snowballing into larger system problems.

Common Challenges and Troubleshooting

No connector is completely immune to wear, environmental stress, or the occasional installation hiccup. Molex connectors tend to be incredibly reliable, but things can still go wrong, especially in demanding applications.

Understanding the typical weak spots helps you fix faults faster and avoid repeated problems.

Connector Failure Causes

Issues with Molex connectors often fall into a few familiar categories:

- Improper crimping: Loose, uneven, or over-crimped terminals can cause signal loss or heat build-up.

- Mating misalignment: Forcing connectors together at the wrong angle bends pins or damages housings.

- Wear from vibration: Over time, movement can create micro-gaps or even disconnect the contacts entirely.

- Contamination: Dust, oil, or oxidised surfaces interfere with electrical flow.

- Overcurrent or overheating: Using a connector beyond its rated limits can cause melted housings or degraded terminals.

Molex Troubleshooting Tips

If something isn’t working, try running through these checks before swapping out components:

- Check the crimp depth and shape – Use a magnifier if needed; inconsistent crimps are a common culprit.

- Test continuity across all pins – Look for intermittent connections that flicker under pressure.

- Visually inspect mating interfaces – Bent or recessed pins are easy to miss at a glance.

- Clean all contacts gently – Use lint-free swabs and isopropyl alcohol to remove any grime.

- Confirm full connector engagement – That satisfying click often means everything’s seated properly.

- Measure heat build-up under load – A warm connector could be carrying more current than it should.

Having a few simple tests in your back pocket can save hours of guesswork and keep your systems up and running with less downtime.

Future Trends in Molex Connectors

As electronics keep shrinking and systems become more integrated, the future of Molex connectors is about doing more with less space and greater performance demands.

Manufacturers are already responding with slimmer profiles, higher-density pin layouts, and materials that hold up under tougher environmental and electrical stress. Molex, in particular, is pushing toward solutions that support miniaturisation without compromising signal integrity, something that’s becoming increasingly relevant in wearables, electric vehicles, and IoT (Internet of Things) devices.

Expect more hybrid connectors, such as ones that combine power, signal, and even fibre optics in a single unit. That means fewer components in the build, faster assembly, and reduced weight, all things that matter in both consumer tech and industrial design.

Another development? Smart cable connectors. These aren’t quite mainstream yet, but there’s growing interest in connectors that can monitor their status, detecting wear, corrosion, or voltage anomalies before failure happens. In some respects, that could shift how maintenance is done altogether.

And on the sustainability front, manufacturers are exploring ways to use recycled plastics and reduce rare metal content without sacrificing performance. As regulations tighten, particularly in Europe, eco-aware engineering choices are moving up the priority list.

The takeaway? The Molex connector guide of tomorrow won’t just list parts; it’ll need to support smarter systems, tighter builds, and cleaner supply chains.

From pinpointing the right series to handling installation like a pro, getting familiar with Molex connectors is more than a box-ticking exercise; it’s a practical way to reduce system errors and keep performance steady. Whether you’re specifying parts for a tight new design or retrofitting older tech, this Molex connector guide should leave you better equipped to make smart, long-term choices.

Their versatility across consumer tech, industrial systems, and automotive setups shows just how dependable they’ve become, and with smart, compact, and hybrid options emerging, their relevance isn’t slowing down.

If you’re looking to integrate Molex connectors into more complex assemblies, our electronic manufacturing services can support your full build from prototype through to production.

Contact us to talk through the right setup for your next project.