Automotive printed circuit boards (PCBs) sit at the heart of modern vehicles, quietly enabling safety systems, infotainment, energy management and advanced driver assistance. Their reliability is non‑negotiable, since even the smallest fault can compromise performance or safety.

This guide explains what makes an automotive PCB different, the materials used, the standards they must meet, and the design challenges engineers face. It also explores the innovations driving next‑generation vehicles, from electric propulsion to autonomous driving.

Whether you are specifying components or assessing suppliers, this article provides a clear, practical resource to help you make informed decisions.

What Is an Automotive PCB?

An automotive PCB is a printed circuit board designed for the unique demands of vehicles. Unlike consumer electronics, these boards must withstand continuous vibration, extreme temperatures and exposure to moisture. They carry signals and power across safety‑critical and performance‑critical systems, meaning durability is a defining requirement. Automotive PCBs tend to be multilayer to accommodate complex routing, and often combine rigid and flexible sections to optimise space.

They are not just electrical backbones, but also thermal conduits, dispersing heat away from components that must operate consistently. Put simply, the automotive PCB is a highly engineered platform, specifically built to meet stringent automotive standards where failure is unacceptable.

Why PCBs Are Critical in Modern Vehicles

Modern vehicles are essentially computers on wheels. Every major function – from starting the engine to adjusting seat comfort – depends on electronics. PCBs are the foundation, connecting sensors, processors and actuators.

In safety applications, such as anti‑lock braking or airbag deployment, boards must deliver signals in microseconds. In performance areas like fuel injection or electric power management, they ensure efficient energy conversion. Comfort and entertainment systems, too, rely on them for seamless integration. Vehicles increasingly depend on PCBs not just for convenience, but for life‑saving accuracy and compliance with regulatory expectations. The sheer diversity of systems – safety, efficiency, comfort, connectivity – makes the automotive PCB critical to overall vehicle reliability.

Without them, modern cars simply could not operate.

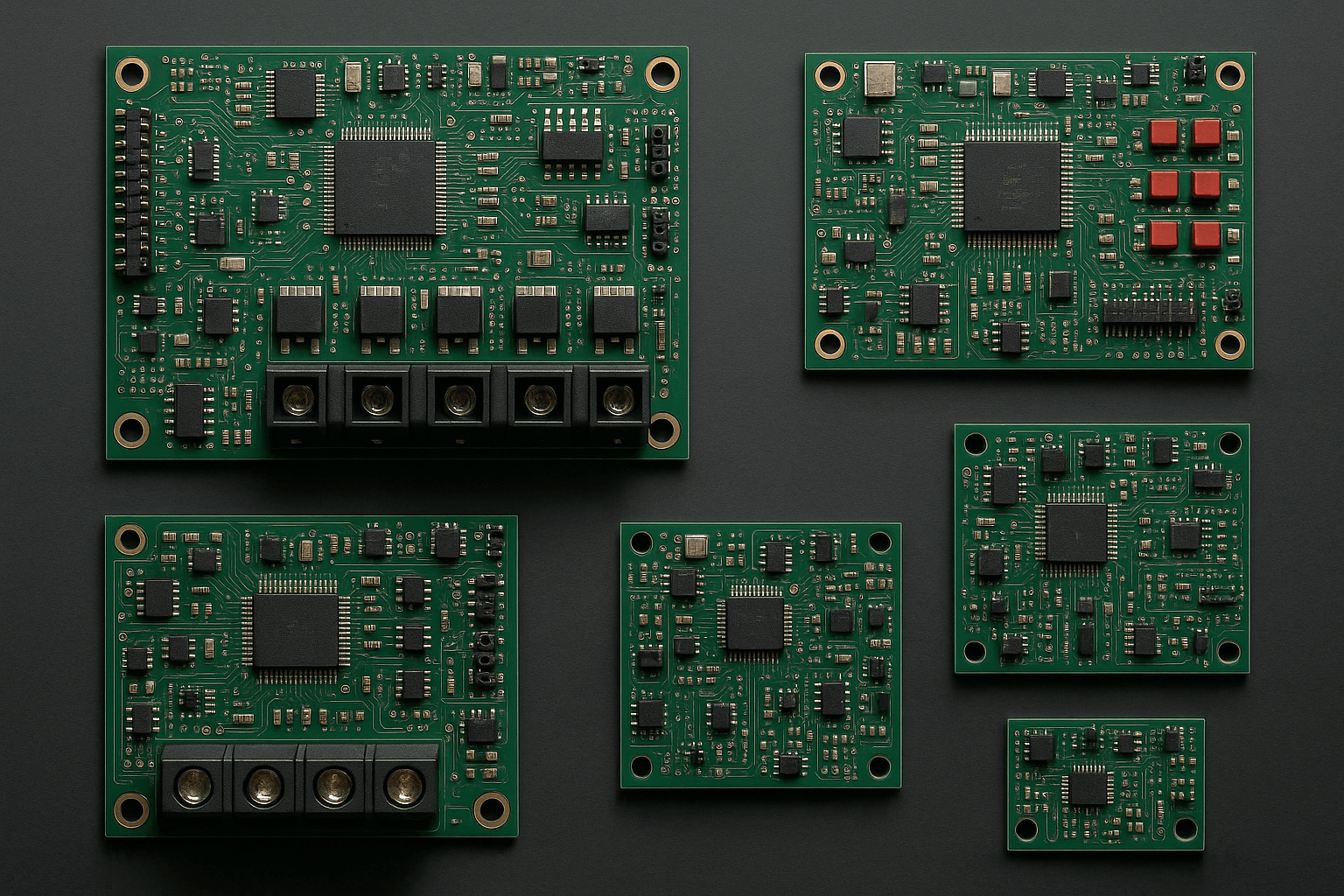

Types of Automotive PCBs

There is no single type of automotive PCB, since each application dictates specific properties:

- Rigid PCBs – the most common type, offering stability and straightforward manufacture, typically used in engine control units.

- Flexible PCBs – thin, bendable substrates ideal for tight spaces, for example, in steering wheel electronics or sensors.

- Rigid‑flex PCBs – hybrids combining rigid stability with flexible adaptability, often used in infotainment and camera modules.

- Multilayer PCBs – boards with several conductive layers for high‑density designs, essential in advanced driver assistance systems (ADAS).

- High‑density interconnect (HDI) PCBs – compact, layered designs that accommodate fine pitch components used in high‑speed communication systems.

The choice of board type often depends on weight, space, thermal demands and required reliability. Each type must still conform to automotive safety and performance requirements, yet the variations allow engineers to align the PCB design to system‑specific needs.

Materials Used in Automotive PCBs

The base material of a PCB is as significant as its design. Automotive applications demand substrates that combine electrical performance with resilience.

- FR‑4 (fibreglass epoxy laminate) is widely used due to its balance of cost and performance, though it may struggle in high‑temperature environments.

- Polyimide substrates offer excellent heat resistance and flexibility, making them suitable for under‑bonnet applications.

- Metal‑core PCBs, often aluminium‑based, provide superior thermal conductivity, commonly used in LED lighting and power electronics.

- High‑frequency laminates are chosen for radar and communication systems, since they maintain signal integrity under demanding conditions.

Material selection is guided by factors like operating temperature, coefficient of thermal expansion and dielectric properties. Engineers must carefully assess how each choice interacts with system requirements.

For instance, a substrate used near a combustion engine must tolerate extreme cycling, while boards in EV battery packs must prioritise thermal conductivity. Materials define how a PCB withstands stress, manages heat and delivers signal fidelity.

Design Considerations for Automotive Applications

Designing PCBs for vehicles means thinking beyond circuits – it involves anticipating mechanical stress, heat dissipation and electromagnetic interference. Engineers must account for:

- Component placement: keep heat‑generating devices spaced to prevent localised hot spots; position safety‑critical components where vibration impact is minimised.

- Signal routing: avoid sharp angles that can disrupt signal integrity; separate analogue and digital lines to reduce interference.

- Thermal management: use thermal vias, copper pours and heat sinks to disperse energy; metal‑core substrates may be considered for higher loads.

- Electromagnetic interference (EMI) and crosstalk: employ ground planes and controlled impedance to limit disruption between high‑speed signals.

- Layer stack‑ups: distribute power and signal layers in ways that optimise performance and manufacturability.

Design must also support manufacturability at scale. This means conforming to Design Rule Checks (DRC), ensuring solder joint reliability and minimising the risk of warpage during assembly.

At every step, designers weigh trade‑offs between compactness, cost, reliability and compliance with international standards. What looks like a small design detail – a via location, or a trace length – can, in fact, determine whether a system passes automotive validation testing.

Good design is less about aesthetics and more about absolute reliability.

Common Automotive Systems That Use PCBs

PCBs permeate every part of a modern vehicle. Some examples include:

- Engine control units (ECUs) – managing ignition timing, fuel injection and emissions.

- Infotainment systems – touchscreens, audio processors, connectivity modules.

- Advanced driver assistance systems (ADAS) – radar, cameras, lidar, and associated controllers.

- Sensor networks – monitoring tyre pressure, exhaust gases, or driver inputs.

- Powertrain and EV systems – managing battery packs, inverters and charging circuits.

- Lighting – from LED headlights to adaptive rear clusters.

Each system has unique performance requirements. For instance, ADAS demands high‑speed data integrity, while lighting modules must balance thermal performance with compact designs. Across all these applications, reliability and compliance with safety standards remain consistent.

Automotive PCBs are not interchangeable; they are purpose built for each system, ensuring both efficiency and safety.

Environmental and Performance Requirements

Few environments are as punishing as an automotive setting. PCBs must endure:

- Thermal cycling: exposure to extreme hot and cold in repeated cycles, from winter mornings to high temperature engine bays.

- Moisture and humidity: protection through conformal coatings to resist corrosion and short circuits.

- Vibration and shock: reinforcement and design features to avoid solder cracks and trace failures.

- Electrochemical stress: materials must resist degradation when exposed to salts, fluids and contaminants.

In addition to physical resilience, boards must perform electrically under stress. This means stable dielectric properties, controlled impedance for high‑speed signals and long‑term solder joint integrity. Automotive systems are expected to function flawlessly for years without intervention. Meeting these requirements ensures passenger safety, regulatory compliance and customer trust.

Performance standards are not aspirational – they are baseline obligations. Engineers and manufacturers know that failing to meet environmental demands can undermine entire vehicle platforms.

Standards and Certifications for Automotive PCBs

Standards provide the framework that separates acceptable designs from automotive‑grade designs. The most recognised include:

- AEC‑Q100/101/200 – stress testing standards for integrated circuits, passive components and discrete semiconductors.

- IPC‑6012 Class 3 – defines requirements for high‑reliability printed boards.

- IATF 16949 – the automotive sector’s quality management standard, ensuring consistent, global compliance.

- UL 796 – covering safety of printed wiring boards.

- RoHS (Restriction of Hazardous Substances) – ensuring environmental compliance.

Conformance is not optional. OEMs and tier‑1 suppliers require documentary proof of compliance before approving a PCB for production. Manufacturers invest in quality systems, traceability tools and external audits to demonstrate adherence. These standards collectively cover performance, safety and environmental aspects.

For instance, IPC‑6012 focuses on workmanship, while AEC standards prove resilience under automotive stresses. Together, they provide assurance that a PCB will function across its intended lifecycle.

For engineers, understanding these standards simplifies supplier assessment – a compliant manufacturer signals reduced risk, greater reliability and fewer costly redesigns.

Challenges in Manufacturing Automotive PCBs

Automotive PCB production involves unique challenges that separate it from other industries:

- Reliability at scale: even a minor defect across thousands of boards can trigger recalls.

- Traceability: every batch must be identifiable for quality audits and compliance.

- Yield management: multilayer and HDI boards can have lower yields; process optimisation is key.

- High‑speed requirements: ensuring signal integrity for ADAS and communication systems.

- Electromagnetic compatibility (EMC): boards must pass rigorous tests to avoid interference.

Manufacturers must continually balance cost with quality. Automotive customers demand low failure rates and consistent delivery schedules. Any lapse can damage reputations or even endanger safety.

To meet these demands, suppliers invest in advanced inspection systems, automated assembly and strict process controls. Manufacturing challenges are not obstacles but defining characteristics of the automotive sector, where expectations for performance and reliability leave little margin for error.

Testing and Quality Control Procedures

Testing validates that each board can withstand real‑world conditions. Quality control is not a final step but an integrated process throughout manufacturing. Common practices include:

- Design Rule Checks (DRC) to verify layouts before production.

- Visual and Automated Optical Inspection (AOI) for defects in traces or solder joints.

- In‑circuit and functional testing to confirm components behave as expected.

- IPC‑A‑600 and IPC‑A‑610 compliance to evaluate workmanship quality.

- Environmental testing, such as thermal cycling, salt fog, or vibration trials.

- Electromagnetic compatibility (EMC) testing to validate that boards do not interfere with other systems.

Automotive customers expect detailed reporting from these processes, offering transparency on performance metrics. Manufacturers often integrate statistical process control to track defect rates and highlight trends. Effective testing ensures that PCBs meet the demanding standards of automotive use before they ever reach an assembly line.

In practice, testing is as much about preventing failures as detecting them. Quality assurance is, in effect, a continuous discipline rather than a box‑ticking exercise.

Innovations in Automotive PCB Technology

Automotive PCBs are evolving to support smarter, cleaner and safer vehicles. Some notable innovations include:

- AI assisted design tools: helping engineers optimise layouts for thermal, signal and cost constraints.

- Embedded components: integrating passive elements within the board to save space and improve reliability.

- High density interconnect (HDI) structures: supporting miniaturisation and faster communication in ADAS modules.

- Advanced substrates: ceramics and high frequency laminates for radar, lidar and high bandwidth data links.

- Thermal solutions for EVs: new materials designed to manage higher voltages and currents in electric vehicles.

These developments are not futuristic ideas but are already being deployed in new vehicle platforms. The pace of innovation reflects the growing reliance on electronics. Each advance pushes PCBs to handle more complexity within smaller footprints while maintaining safety.

For engineers and procurement teams, staying aware of these trends ensures long‑term competitiveness.

Trends in Automotive Electronics and PCB Demand

Several trends explain the surge in demand for automotive PCBs:

- Electrification: growth of hybrid and battery electric vehicles creates higher requirements for thermal performance and power density.

- Autonomy: ADAS features generate unprecedented data volumes requiring high‑speed interconnects.

- Connectivity: vehicle‑to‑everything (V2X) systems demand reliable high‑frequency boards.

- Integration: more systems consolidated into fewer controllers, leading to higher‑layer PCBs.

As electronics become the differentiator between models, demand for advanced PCBs grows. OEMs increasingly see PCB design and supply chain strategy as competitive advantages.

For suppliers, this trend represents both opportunity and challenge – the market demands innovation, but margins remain tight. Engineers evaluating suppliers should expect to see clear roadmaps aligned with these long‑term automotive electronics trends.

Future Outlook: EVs, ADAS and Autonomous Vehicles

Looking ahead, the future of PCBs is tied to the rise of electrification and autonomy. Electric vehicles demand boards capable of handling higher voltages, power density and heat dissipation. ADAS and autonomous systems increase the need for high speed, multi layer boards that can transmit and process vast data volumes in real time.

Reliability takes on a new dimension, since a PCB failure in an autonomous vehicle can compromise functional safety at the highest level. Manufacturers are already investing in research on materials with better dielectric properties and substrates with improved thermal coefficients.

At the same time, regulations will tighten, mandating stronger proof of compliance. Engineers and procurement teams will need suppliers who are not just compliant today, but forward‑looking enough to anticipate the needs of tomorrow’s vehicles. PCB technology will increasingly be a defining factor in automotive progress.

Choosing the Right PCB Partner for Automotive Projects

Selecting the right supplier is as important as the design itself. Key factors to assess include:

- Quality certifications: IATF 16949, IPC‑6012 Class 3 and UL approvals.

- Experience with automotive standards: proven track record in meeting AEC testing protocols.

- Testing capabilities: in‑house environmental and EMC validation, plus robust reporting.

- Design support: offering design for manufacturability (DFM) input and layout review.

- Supply chain reliability: capacity to deliver consistently, with strong traceability systems.

- Scalability: ability to support pilot runs as well as volume production.

For procurement teams, these points form a checklist that simplifies supplier comparisons. A good partner will not just supply boards, but will collaborate on improving design outcomes and ensuring compliance. Costs matter, but long‑term reliability and service continuity are often more decisive. Working with a manufacturer that prioritises transparency and continuous improvement reduces risk.

For organisations seeking a proven partner in this field, Altimex provides full support in PCB assembly, backed by strong process controls and decades of expertise.

Automotive PCBs are the foundation of modern vehicles, supporting everything from safety to comfort. Their design and manufacture demand specialist knowledge, compliance with international standards and forward thinking suppliers. You should now be a lot clearer with the outlined definitions, materials, design practices, challenges, testing procedures and future trends shaping the industry.

Success relies on more than design skill – it requires trusted partnerships with manufacturers committed to quality. To discuss your automotive PCB requirements or request expert advice, please contact us at Altimex today.