In recent years, the demand for recyclable products has surged, reflecting a growing awareness of the need to enhance the sustainability of businesses across industries.

This shift towards eco-conscious practices extends to the realm of electrical engineering and electronics, where the recycling of electricals, including the meticulous process of PCB recycling, plays a pivotal role.

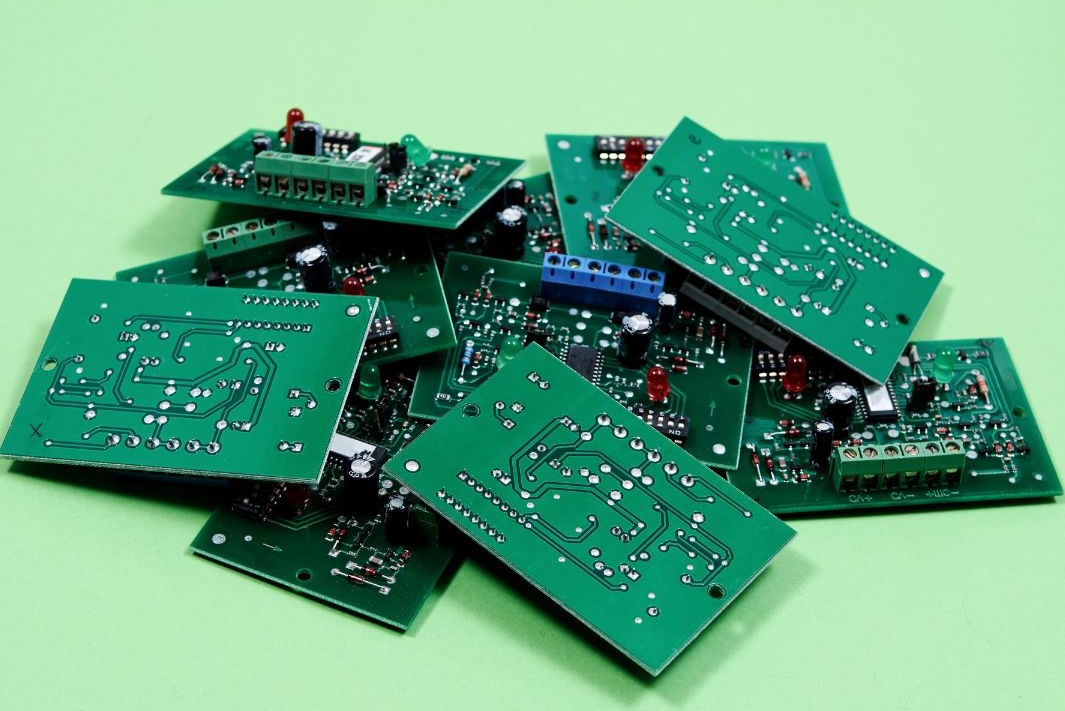

Circuit boards, or PCBs, integral to virtually all electronic devices, present a unique challenge and opportunity in the recycling sector.

This article aims to guide engineers and electricians on how to recycle PCBs effectively, ensuring that sustainable PCBs recycling contributes positively to their efforts.

Are Printed Circuit Boards Recyclable

In the realm of electronics manufacturing, Printed Circuit Boards (PCBs) are ubiquitous, and composed of valuable metals and materials that underscore their recyclability.

However, the improper disposal of these components poses significant environmental threats, contributing to pollution and resource depletion. This underscores the urgency of adopting responsible recycling practices.

Globally, the environmental consequences of mishandling PCBs have catalysed stringent regulations governing the disposal of electronic waste, highlighting the legal imperatives for recycling.

For engineers and electricians, understanding these regulations is critical, ensuring that the recycling of PCBs is conducted in compliance with legal obligations, thus contributing to a more sustainable and environmentally responsible industry.

How are PCBs Recycled

There are several various ways in which PCBs can be recycled, here are the three main routes that can be taken with recycling such materials.

1. Thermal Recovering

The thermal recovery method, a pivotal technique in PCB recycling, utilises heat to decompose the components of circuit boards, facilitating their reuse.

This process offers significant environmental advantages, including reduced energy consumption and minimised emissions, aligning with sustainable practices.

Despite its benefits, thermal recovery faces challenges, such as the potential release of toxic substances.

However, ongoing innovations are enhancing its efficiency, making it a more viable and environmentally friendly option for recycling PCBs, thereby addressing both the technical and ecological aspects of electronic waste management.

2. Physical Recovering

Physical recovering methods, employing mechanical separation, are at the forefront of recycling Printed Circuit Boards (PCBs).

This approach facilitates the extraction of valuable metals and materials, contributing significantly to the circular economy by ensuring resources are reused rather than discarded.

Recent technological advancements have greatly enhanced the effectiveness of these methods.

Innovations in separation techniques and machinery have improved the efficiency and precision of extracting valuable components from PCBs, showcasing the evolving nature of recycling practices and their crucial role in sustainable waste management.

3. Chemical Recovering

The chemical recovery process plays a crucial role in recycling Printed Circuit Boards (PCBs), using chemicals to dissolve and extract valuable materials.

While effective, this method raises environmental concerns due to the potential release of harmful substances.

Efforts are underway to mitigate these effects, with advancements in safer chemicals and processes.

Chemical recovery boasts efficiency in extracting precious metals, yet it faces limitations regarding its environmental impact.

Balancing these factors is key to advancing PCB recycling while minimising ecological footprints, illustrating the complex interplay between technological efficiency and environmental stewardship.

Is Recovered Copper from PCBs Recyclable?

In recycling copper from PCBs, various techniques play a crucial role in maximising resource efficiency and minimising environmental impact. Among these methods, edge trim recycling stands out as a significant opportunity to harness valuable materials that would otherwise end up in landfills.

Edge Trim

Edge trim, the excess material trimmed from Printed Circuit Boards (PCBs) during manufacturing, represents a significant recycling opportunity.

Collecting this waste for recycling is a key sustainability practice, preventing valuable resources from ending up in landfills.

Recovered copper from edge trim can be repurposed for various applications, from electronics to renewable energy components, showcasing its versatility and economic value.

Emphasising sustainability, the recycling of edge trim not only conserves resources but also contributes to a more circular economy, underlining the importance of such practices in the industry.

Hot Air Levelling

Hot air levelling, a pivotal process in the manufacture of Printed Circuit Boards (PCBs), plays a significant role in the recycling of copper.

This technique involves blowing hot air over the surface to level the solder, facilitating the recovery of high-quality copper.

The recovered copper, known for its purity, is highly valued across various industries, from electronics to construction.

The adoption of hot air levelling not only enhances the efficiency of copper recycling but also underscores the industry’s commitment to sustainable practices.

This process exemplifies how innovative techniques can contribute to the circular economy, maximising resource utilisation while minimising waste.

Etching

Etching, a critical process in the recycling of copper from Printed Circuit Boards (PCBs), involves using chemicals to remove unwanted materials, leaving behind pure copper.

This method is increasingly refined to minimise ecological harm, with advancements in environmentally friendly chemicals and waste treatment practices.

The copper recovered through etching meets high purity standards, making it suitable for reuse in electrical applications.

Efforts to enhance the etching process underscore the industry’s commitment to sustainable recycling practices, ensuring that the extraction of copper not only conserves resources but also aligns with environmental stewardship.

Wastewater Sludge

The recovery process from Printed Circuit Boards (PCBs) generates wastewater sludge, a complex mixture containing metals, solvents, and other residues.

Treatment methods for this sludge are critical for mitigating environmental impact, involving chemical stabilisation, dewatering, and, in some cases, thermal treatment to reduce its hazardous content.

Proper disposal practices are strictly regulated, ensuring that treated sludge is safely disposed of or repurposed following environmental standards.

Implementation of these innovative techniques underscores the industry’s dedication to sustainable waste management in PCB recycling, ultimately reducing the ecological footprint of the process.

For more information on PCB recycling and the best PCB applications, feel free to contact us here at Altimex. Our team provides tailored support and guidance to meet your needs for sustainable recycling practices.