It is crucial to gather comprehensive information from an EMS contract manufacturer before engaging their services for your project.

Making informed decisions ensures smooth collaboration and satisfactory outcomes in EMS contract manufacturing.

Therefore, before finalising any agreements, it is imperative to ask pertinent questions to ascertain compatibility and competence.

By addressing specific inquiries, engineers, electricians, and automotive workers can ensure that their EMS contractor aligns with their project requirements and standards.

1. What is your quality control process?

When considering an EMS contract, it’s essential to query about their quality assurance protocols.

You will want to consider what measures they have in place to ensure product quality throughout the manufacturing process.

Not only that but how do they handle defective components or products and can they provide documentation or evidence of previous quality control successes?

These inquiries are important for establishing confidence in your EMS contracting decision, ensuring that your partner talks about quality and demonstrates a proven track record of it.

2. Is your business financially stable?

In the process of selecting an EMS contractor, it’s imperative to assess their financial robustness.

Queries such as can you provide financial statements or other evidence of financial stability, how long they have been in business, and what is their track record of financial success can give further insight.

Additionally, ask them if they have any partnerships or contracts that demonstrate stability as it can offer insights into their reliability and longevity in the industry, guiding engineers, electricians, and automotive workers towards making an informed EMS contracting decision.

3. Do you have any industry certifications?

In your EMS contractor evaluation, it’s pivotal to find out which certifications are relevant to the industry they possess.

Understanding how these certifications ensure compliance and quality in manufacturing is crucial.

4. What supplier management system do you use?

When discussing with a potential EMS contractor, it’s critical to ask, “How do you select and manage your suppliers?”

Delve further by inquiring about their process for evaluating and monitoring suppliers, and how they guarantee the reliability and quality of components.

Such questions are essential for ensuring a robust and dependable supply chain.

5. Do you have a dedicated point of contact?

In your dialogue with a prospective EMS contractor, it’s imperative to inquire, “Will there be a single point of contact for communication throughout the project?”

Further, question the accessibility of this contact and probe into their level of expertise and authority within the organisation, ensuring streamlined and informed communication channels.

6. Do you have an NPI (New Product Information) Process?

In your assessment of a potential EMS contractor, it’s essential to ask, “Can you outline your New Product Introduction (NPI) process?”

Explore how they manage the transition from prototype to full-scale production and inquire about their experience with NPI within your specific industry, ensuring their capabilities align with your project’s demands.

7. Can you provide any testimonials from your customers?

Requesting testimonials or references from previous clients is critical to gauge satisfaction and performance.

Analyse these testimonials for consistency, reliability, and relevance to your needs.

It’s also prudent to seek feedback on specific areas such as quality, communication, and meeting deadlines, ensuring the EMS contractor meets your expectations.

8. Can you protect our intellectual property?

Inquiring about the contractor’s policies for safeguarding intellectual property is vital.

Discuss the implementation of confidentiality agreements and non-disclosure agreements to protect sensitive information.

Additionally, clarify ownership rights and responsibilities regarding any intellectual property developed during the partnership, ensuring your innovations are securely managed and legally protected.

9. Can you meet tight project requirements and deadlines?

Assess the EMS contractor’s track record of meeting project deadlines and managing time-sensitive tasks.

Discuss their strategies for risk management and mitigation that could affect timelines.

It’s also crucial to determine the flexibility and scalability of their operations to ensure they can accommodate varying project demands efficiently.

10. Are you able to handle complex orders?

Evaluate the EMS contractor’s experience in handling complex projects or customised orders.

Inquire about their capabilities in managing intricate manufacturing processes and technical requirements.

Discussing examples of previous projects can shed light on their ability to handle complexity effectively, ensuring they possess the requisite expertise for your specific needs.

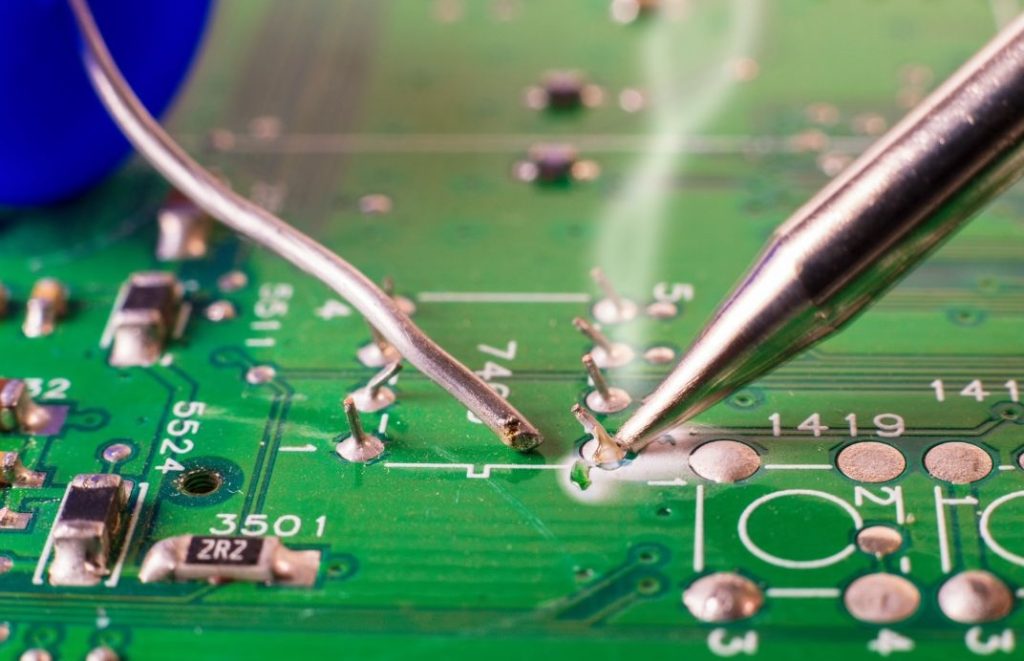

11. Is your equipment up to date?

Engage with your prospective EMS contractor on their investment in cutting-edge manufacturing equipment and technology.

It’s crucial to assess their machinery’s capabilities and specifications for compatibility with Altimex’s specific needs.

Additionally, a discussion of their maintenance and upgrade protocols is essential for ensuring ongoing performance and reliability in your projects.

12. Can you add value during the design process?

Discuss the contractor’s role in the design phase and their capacity to contribute valuable insights or improvements.

Explore avenues for collaboration to enhance product design for manufacturability and cost-efficiency.

Additionally, request examples of previous projects where the contractor offered design enhancements or cost-saving suggestions, demonstrating their proactive approach and expertise.

13. Are you fully up to speed with industry standards?

Inquire about the contractor’s familiarity and compliance with industry standards and regulations pertinent to Altimex’s products.

Discuss their dedication to continuous training and certification, ensuring alignment with industry advancements.

Additionally, evaluate their quality assurance and compliance strategies throughout the manufacturing process to guarantee product integrity and safety.

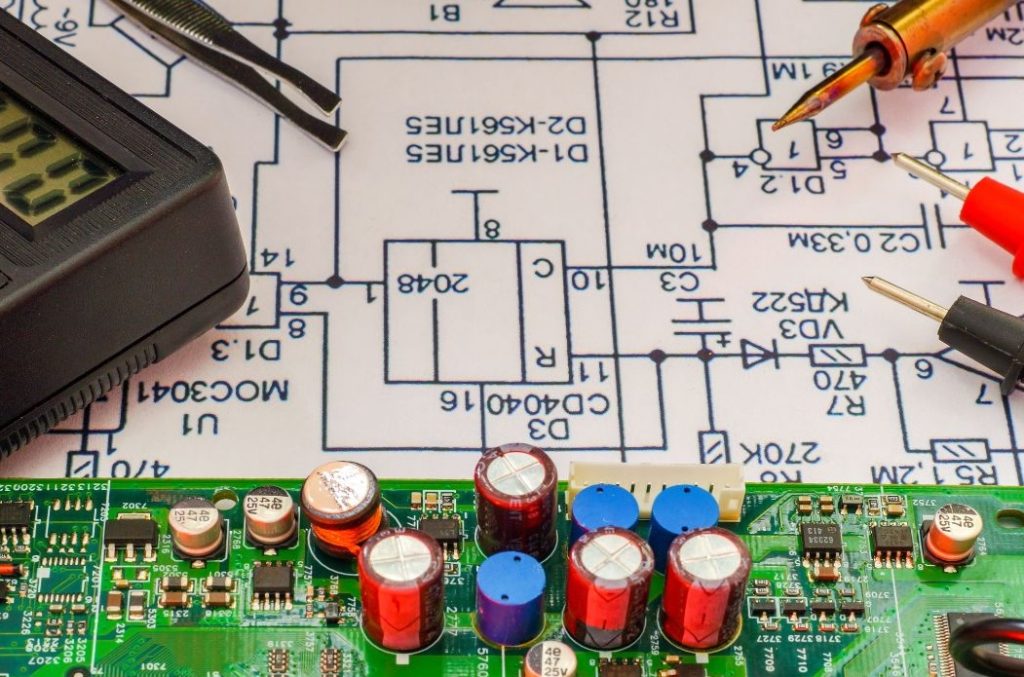

14. How do you handle traceability?

Discuss the contractor’s traceability systems for tracking materials, components, and products throughout the supply chain.

Inquire about their capability to trace and document product origins, changes, and destinations.

Evaluate their proficiency in providing transparent and accurate traceability information, essential for regulatory compliance and quality assurance, to ensure a robust and reliable manufacturing process.

15. Are you able to strategically align with business goals?

Discuss the contractor’s grasp of Altimex’s business goals and long-term vision, exploring strategic alignment in product innovation, market expansion, or cost reduction.

Evaluate their readiness and ability to adapt to Altimex’s evolving needs and priorities, ensuring a partnership that is not only current but also forward-looking and dynamic.

For further information on how our services can support your projects, please do not hesitate to contact us at Altimex.