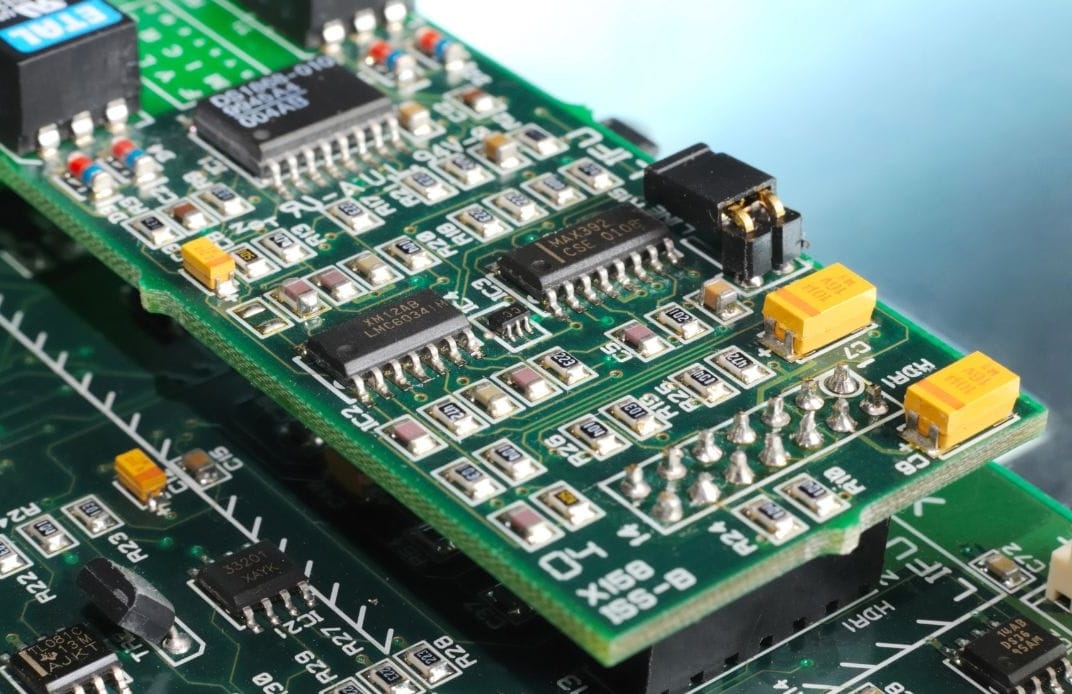

When designing or sourcing a PCB, one of the first considerations is the method of mounting components. The choice between Surface Mount Technology (SMT) and Through-Hole Technology (THT) directly impacts design flexibility, manufacturing speed, durability and overall performance.

SMT involves soldering components directly to the PCB surface, while THT uses drilled holes through which component leads are inserted and soldered. Each method has distinct strengths and limitations, making the decision critical in both design and procurement.

This article explores SMT vs THT in detail, offering a clear comparison of their processes, applications and suitability. By the end, you will know which method aligns best with your requirements, and how professional PCB assembly services like Altimex can support both.

Mounting Method and Component Placement

The most obvious distinction lies in how components are attached to the board:

| Feature | Surface Mount Technology (SMT) | Through-Hole Technology (THT) |

| Mounting style | Components soldered directly onto PCB surface pads | Leads inserted through drilled holes and soldered |

| Component size | Very small (e.g., 0402, QFN, BGA) | Larger, bulkier packages |

| Density | High-density placement possible | Lower density due to hole spacing |

| Board design | Double-sided mounting supported | Typically single-sided |

SMT enables highly compact layouts by eliminating the need for holes, making it ideal for miniaturised designs. THT, by contrast, provides a stronger mechanical attachment since component leads extend through the board.

Understanding these differences is the first step in evaluating which PCB mounting method best suits a particular project.

Assembly Process and Equipment Requirements

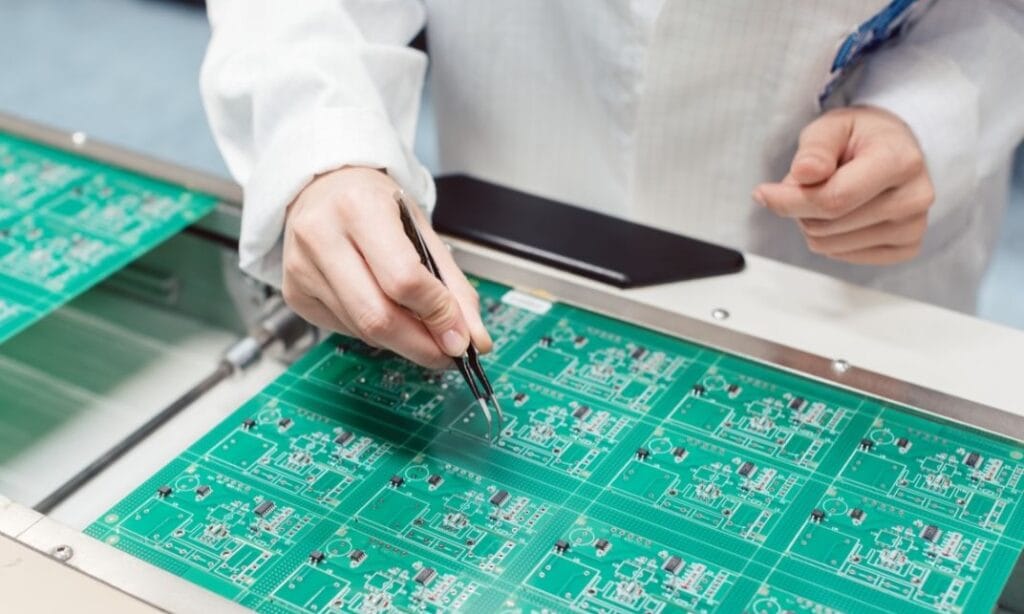

The surface mount assembly process is largely automated. Stencils apply solder paste, pick-and-place machines position components, and reflow ovens solder everything in place. Automated optical inspection (AOI) systems verify quality at scale. SMT lines can place tens of thousands of components per hour with consistency. In comparison, through-hole soldering is more labour-intensive.

Leads are inserted into drilled holes and secured using wave soldering or manual soldering stations. While wave soldering offers partial automation, it is slower and less flexible than SMT reflow. THT often requires more operator intervention, which adds to production costs and extends lead times.

For large-scale projects, SMT usually provides faster throughput, while THT may be preferred in prototypes or lower-volume builds where automation is less critical.

Size, Weight and Design Flexibility

Modern electronics demand compactness. SMT excels here by supporting tiny packages and double-sided placement, allowing engineers to design slim, lightweight devices.

Smartphones, wearables and tablets all rely on SMT’s ability to integrate thousands of components within a minimal footprint. THT, on the other hand, is less space-efficient. Leads and drilled holes limit density and restrict placement options.

However, THT still has value where large components or connectors are required. For example, transformers and high-power resistors often depend on through-hole mounting due to their size and thermal dissipation needs.

When weight and miniaturisation are top priorities, SMT wins. When mechanical constraints or heavy-duty components are involved, THT remains the better option.

Mechanical Strength and Durability

Through-hole connections are mechanically stronger because component leads are soldered through the PCB, anchoring them securely. This makes THT suitable for applications exposed to stress, vibration or physical force.

THT mechanical advantages:

- Better resistance to pull-out forces.

- Stronger bonds for large or heavy components.

- Suited for aerospace, automotive and military electronics.

THT disadvantages:

- Larger holes reduce available board space.

- Slower assembly process compared with SMT.

SMT components, being smaller and surface-mounted, are less resistant to mechanical stress. However, SMT still delivers adequate durability for most consumer electronics and is perfectly reliable in normal operating environments.

For mission-critical hardware subjected to extreme stress, THT provides reassurance. For compact, everyday devices, SMT durability is sufficient and preferred.

Electrical Performance and Signal Integrity

SMT components typically deliver superior electrical performance. Shorter leads mean reduced parasitic inductance and capacitance, which enhances high-frequency signal integrity. This is vital in applications such as 5G communication, high-speed computing and advanced automotive systems. THT, with its longer lead lengths, introduces slightly higher parasitics that can degrade performance at very high frequencies.

That said, THT can still perform well in lower-frequency or high-power circuits where mechanical reliability outweighs small electrical inefficiencies. For engineers prioritising compact high-speed design, SMT is the clear choice. For power electronics and ruggedised systems, THT’s electrical characteristics remain more than adequate.

Manufacturing Speed and Cost

SMT assembly is highly scalable, with automated processes ensuring speed and repeatability. Once a line is set up, per-unit costs are low, especially for large volumes. THT, being more manual, is slower and more expensive at scale. Drilling holes adds process steps, while manual soldering increases labour costs.

For prototypes or small batches, however, the cost difference may be less significant, and THT can even be faster for simple layouts. When moving to mass production, SMT advantages in throughput and efficiency dominate. This is why most modern PCB assembly facilities invest heavily in SMT equipment, while maintaining selective THT capability for niche requirements.

Repairability and Prototyping Ease

Through-hole boards are generally easier to repair and modify. Components can be desoldered and replaced with basic tools, making THT attractive for prototyping or educational environments. SMT repair, on the other hand, requires specialist equipment like rework stations and microscopes, since components are so small. This makes SMT less practical for quick modifications or hobbyist use.

For R&D labs, THT remains the method of choice when frequent design changes are expected. For final production runs, where consistency and density matter more than ease of repair, SMT is preferred.

The choice often depends on whether a project is still experimental or heading to scale.

Common Applications and Industry Use Cases

Different industries lean on each method for different reasons:

- SMT applications: smartphones, laptops, wearables, medical implants, automotive sensors, telecom hardware.

- THT applications: aerospace avionics, military-grade equipment, industrial machinery, high-power supplies.

This distinction reflects each method’s strengths. SMT dominates in consumer and commercial devices that demand small size, high speed and cost efficiency. THT persists in environments where reliability under stress and mechanical robustness are critical.

Hybrid boards are also common, combining SMT for logic and small components with THT for connectors or power devices. Altimex supports both approaches, tailoring PCB assembly methods to meet the specific application requirements of each project.

Suitability for High-Density Circuitry

High-density designs are where SMT excels. Fine-pitch ICs, ball grid arrays (BGAs) and double-sided boards all depend on surface mounting. SMT allows more components per square centimetre, supporting the miniaturisation trend across industries. THT, due to its reliance on drilled holes, cannot compete in these applications.

That said, hybrid designs often incorporate THT connectors or high-power parts alongside dense SMT layouts. For cutting-edge electronics with tight spacing, SMT is the only viable option. For rugged or heavy-duty boards, THT still plays a complementary role.

Future Outlook for Both Technologies

The future clearly leans toward SMT, with its role in high-density, high-performance electronics growing year by year. Innovations like micro-BGAs, 3D packaging and automated optical inspection keep SMT evolving. However, THT will not disappear.

Aerospace, military and industrial sectors continue to rely on its mechanical resilience, and hybrid approaches are increasingly common. Procurement teams should expect SMT to dominate most volume production, with THT reserved for specialised components.

Altimex remains committed to offering both technologies, ensuring that clients can select the method – or combination – that best balances performance, durability and cost for their project.

Surface Mount Technology and Through-Hole Technology each offer distinct benefits. SMT provides speed, compactness and scalability for today’s high-performance electronics, while THT delivers mechanical strength and reliability for demanding conditions.

Choosing between them depends on project priorities, whether that is density, durability or ease of repair. Altimex offers professional PCB assembly services in both SMT and THT, supporting hybrid solutions where needed.

To discuss your project requirements and find the best fit, please contact us for expert guidance.