Drilling holes in printed circuit boards (PCBs) is a large part of electronics manufacturing and DIY projects. Whether you’re working on a multi-layered board for a commercial product or a simple design for a hobby project, the method you choose for drilling directly impacts the precision and outcome of your work.

From manual tools to automated solutions, several methods exist to create the necessary holes in a PCB. In this article, we’ll cover how to drill holes in a PCB and four common PCB drilling methods, detailing their uses, challenges, and the types of projects they suit. By the end, you’ll be better equipped to select the most suitable method for your specific project needs.

1. Using a Handheld Rotary Tool

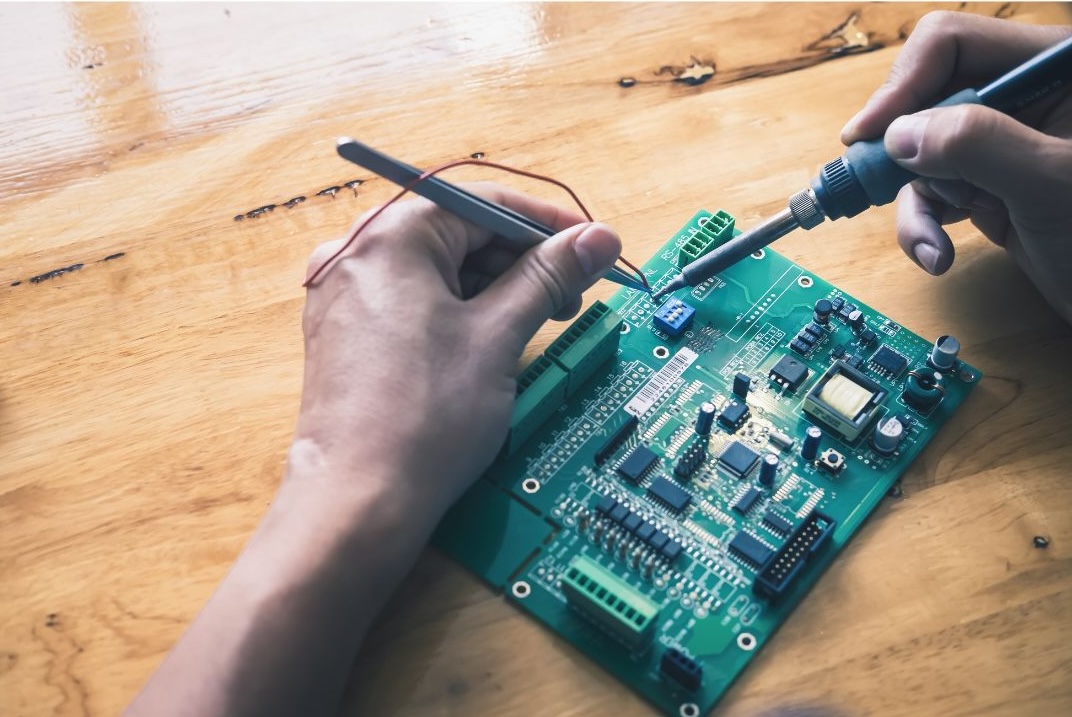

For hobbyists and small-scale projects, handheld rotary tools, such as a Dremel, provide an affordable and accessible option for drilling holes in PCBs. These tools are favoured for their ease of use and availability, making them a popular choice among electronics enthusiasts.

When using a handheld rotary tool, you need to select the correct drill bit size and material, such as tungsten carbide, which is durable enough to handle the delicate nature of PCBs. However, the precision of this method depends heavily on the user’s skill and technique. Handheld rotary tools can sometimes lead to inaccuracies, especially when drilling multiple holes, due to the lack of stability.

While this method is cost-effective and convenient for DIY projects, it does come with limitations. The lack of precision and potential for user error makes handheld rotary tools less ideal for projects that demand high accuracy or consistency across multiple boards.

2. Drilling with a PCB Drill Press

A PCB drill press is an excellent upgrade from handheld tools for those requiring greater accuracy and stability. This means that holes are drilled straight and at consistent depths, making it ideal for projects involving multiple PCBs or requiring more precision.

The fixed nature of a drill press eliminates much of the instability found with handheld rotary tools, allowing users to maintain better control over the drilling process. This makes it a preferred method for more intricate designs where precision is key. The drill press is also adaptable to various bit sizes, enabling the creation of different hole diameters with ease.

However, setting up a PCB drill press can be time-consuming, and the equipment itself is a larger investment than handheld tools. Safety precautions are also required, as the machine’s power can cause damage if not used correctly. Despite these factors, the benefits of accuracy and consistency make a drill press highly suitable for professionals and dedicated hobbyists working on detailed PCB designs.

3. Laser Drilling for Precision

This is a popular method for achieving high precision, particularly when working with microvias in multi-layered PCBs. Unlike mechanical drilling, which involves physical contact, laser drilling uses a focused beam of light to create holes without wear on the drill bit. This technique is especially useful for producing very small holes, often less than 0.1mm in diameter, making it suitable for advanced electronics manufacturing.

The main benefits of laser drilling PCB holes are its precision and consistency across complex designs. It is widely used in industries where accuracy is essential, such as in high-end electronics and aerospace applications. Additionally, because there’s no physical contact, the risk of damaging delicate PCB materials is minimised.

However, laser drilling requires specialised equipment, which can be expensive to acquire and maintain. This makes it less accessible for small-scale operations or hobbyists. Due to the higher costs and setup requirements, laser drilling is generally used in large production runs where precision is a top priority.

4. Using CNC Machines for Automated Drilling

Computer Numerical Control (CNC) machines provide a fully automated solution for drilling PCBs, offering both speed and accuracy. These machines are commonly used in mass-production environments where consistent results are needed. CNC machines can be programmed to follow precise drilling patterns, which means that each hole is placed exactly as needed, with minimal human intervention.

One of the main benefits of CNC drilling PCB is its repeatability. Once the program is set, the machine can drill hundreds or even thousands of PCBs with the same level of precision. This makes CNC drilling ideal for large-scale operations, where accuracy and efficiency are needed. The automation aspect also reduces the risk of human error, making the process more reliable.

However, CNC machines require a significant investment, both in terms of cost and setup. For smaller operations or hobbyists, the complexity and expense of CNC drilling for PCB holes may outweigh the benefits. But for manufacturers handling large production runs, the precision and efficiency offered by CNC machines can be well worth the investment.

Drilling holes in PCBs is a major part of electronics manufacturing, and the method you choose can significantly affect the outcome of your project. From handheld rotary tools for simple DIY tasks to advanced CNC machines for mass production, there are solutions available for a variety of needs. Handheld tools offer accessibility and affordability, while methods like laser and CNC drilling provide the precision needed for more complex designs.

When selecting the best method for your project, consider factors like budget, the scale of your operation, and the level of precision required. By understanding the strengths and limitations of each technique, you can choose the most suitable option to make sure of your project’s success.