In an era of rapid technological advancement and increasing urbanisation, the significance of fire safety for cables has never been more critical.

Across the globe, in bustling metropolises like London, the safety of individuals inhabiting and working within diverse buildings is paramount. It is not merely a moral duty of employers to ensure the safety of their occupants but, in most cases, a legal obligation as well.

Fire regulations ensure businesses adhere to correct safety protocols, helping to mitigate potential disasters, injuries and fatalities.

However, these regulations vary across different regions and industries, leading to scenarios where a cable permitted indoors in one location may be strictly prohibited in the same type of building elsewhere.

Additionally, fire safety regulations are subject to frequent changes, so you must keep up to speed with cabling standards before purchasing fibre optic cables.

So, we have devised this article to help you choose safe fibre optic cables that are appropriate for your business, delving into why fire regulations are necessary and how to ensure your fibre optic cable installation meets requirements.

Why Do We Need Fire Regulations on Fibre Optic Cables?

Fire regulations are vital when it comes to the installation and use of fibre optic cables. These regulations stem from understanding the critical role fire safety provides, such as preserving lives, and preventing injuries.

It’s essential to delve into the three fundamental aspects of fire safety and how they relate to fibre optic cables.

Fire Prevention and Optic Fibre Cables

Fire prevention underscores the necessity of ensuring that fires do not initiate inadvertently or even intentionally.

Although not typically associated with sparking fires, fibre optic cables must adhere to stringent regulations to minimise potential risk. Their installation and maintenance must meet exacting standards to prevent accidental damage or ignition.

This proactive approach is essential in mitigating fire hazards in various building types and industries where fibre optics are prevalent.

Fire Control and Optic Fibre Cables

Fire control measures are equally vital, as they aim to ensure that fires, should they arise, do not escalate uncontrollably.

Using flame-retardant materials in fibre optic cables is imperative to contain fires within manageable parameters, preventing extensive damage and minimising the risk to occupants.

Evacuation and Optic Fibre Cables

In situations necessitating firefighting intervention and evacuations, the compliance of fibre optic cables with safety regulations is pivotal.

These cables traverse buildings and infrastructures, often intersecting evacuation routes. Ensuring their fire resistance and structural integrity allows firefighters and rescue teams to operate safely and effectively.

For example, cables need to be adequately supported in a building using non-combustible fixings. This requirement safeguards against premature collapse in the event of a fire, helping firefighters to access all areas of a building safely.

Choosing The Right Fibre Optic Cable For The Right Setting

In the United Kingdom, regulatory standards often align closely with international norms, particularly the IEC/CEI standards, reflecting a commitment to global best practices in the cable industry.

It’s essential to recognise that specific cable types are designed to deliver distinct advantages in various environmental contexts, indoors or outdoors. These cables are designed with particular attributes tailored to meet the demands of their intended usage.

A notable example includes cables that feature low-halogen properties. Low-halogen cables are engineered to emit minimal smoke, particularly when exposed to high temperatures. Low-smoke cables are a crucial safety aspect, as the absence of halogen chemicals in the smoke produced by these cables prevents the release of toxic fumes.

In essence, these cables minimise the environmental impact of smoke generation, reducing the health hazards associated with inhaling toxic substances during a fire emergency.

In Europe, regulations prioritise controlling smoke density and toxicity over flame propagation. As mentioned, local regulations, such as those by the BSI in the UK, may align with IEC/CEI standards, but it’s advisable to verify compliance with local authorities.

What Do The Cable Fire Regulations State?

Ensuring that cables adhere to the stringent IEC/CEI standards is paramount in fire safety design for buildings and electrical installations.

These regulations encompass a wide spectrum of requirements for electrical and electronic technologies, such as how they are developed and how they perform to ensure optimum environmental safety. This expansive scope encompasses most fibre optic cables utilised within buildings.

A critical stipulation, as outlined in the IEC/CEI standards, underscores the imperative need for all cables to be adequately supported using fixing devices and cable ties, as mentioned previously in this article.

Appropriate cable ties are classified by their material, tensile strength, minimum and maximum temperatures, and resistant to certain elements.

Let’s explain why adequate support and appropriate material are necessary when installing fibre optic cables.

In a contemporary building, an extensive cabling network intricately weaves through its infrastructure, providing essential data connections and power.

However, the ferocity of a fire can subject these cables and their housings to intense heat, rendering them vulnerable to failure. The dire consequence is the release of falling and fallen lines, a hazardous situation faced by evacuees and, notably, firefighters moving in and through the building.

Essentially, this regulation mandates the secure affixation of cables, employing appropriate clips and supports with a melting point sufficiently high enough to withstand the scorching temperatures of a fire.

Materials such as plastic and aluminium, which may falter in the face of extreme heat, are deemed inadequate as a sole form of support.

How To Ensure A Fibre Optic Cable Installation Meets Fire Regulations

You must select a cable that adheres to IEC/CEI standards to ensure compliance with rigorous fire safety and electrical installation standards.

Additionally, install Arc Fault Detection Devices (AFDD) in specific environments where fire safety is of paramount concern.

An AFDD (Arc Fault Detection Device) is an electrical safety device that monitors circuits for potentially dangerous arc faults caused by loose or damaged electrical connections, which can lead to fires.

When the device detects such irregularities in the electrical waveform, it immediately disconnects the circuit, reducing the risk of fire.

AFDDs are crucial safety features, particularly in environments with fire hazards or sensitive electrical equipment, as they enhance electrical fire prevention and overall safety.

Install AFDD in specific environments, such as the following:

Premises with Sleeping Accommodation

AFDDs are essential in residential buildings, hotels, dormitories, or areas where people sleep to detect and respond to fire risks swiftly.

Locations with Heightened Fire Risk

Install AFDDs in environments that contain processed or stored materials prone to combustion, including BE2 locations, such as barns, woodworking shops, and areas housing combustible substances.

Locations with Combustible Construction Materials

AFDDs are critical in fire prevention and early detection in buildings constructed with wooden structures or other flammable materials.

Fire Propagating Structures

Install AFDDs in spaces where fire can spread rapidly, such as high-rise buildings, helping to contain potential fire outbreaks.

Locations with Endangering of Irreplaceable Goods

Museums, art galleries, or heritage sites benefit significantly from AFDDs to protect priceless items in the event of a fire.

The Best Fibre Optic Cables To Meet UK Fire Regulations

Our fibre patch cords at Altimex are ideal for UK installations due to the low-smoke and halogen-free materials they are made of.

All of our assemblies are fully tested before delivery and supplied with test results.

We can also manufacture cables to meet your specific requirements.

For example, the SC, LC and ST connectors are standard, but others are available.

OM1 62.5/125 LC-LC Duplex Fibre Optic Patch Cord

The OM1 fibre optic cable is used in 1000Base networks, often in LAN/enterprise and legacy networks.

We supply this cable with a grey LSZH (low smoke, zero halogen) cable jacket as standard; however, it is available in other colours.

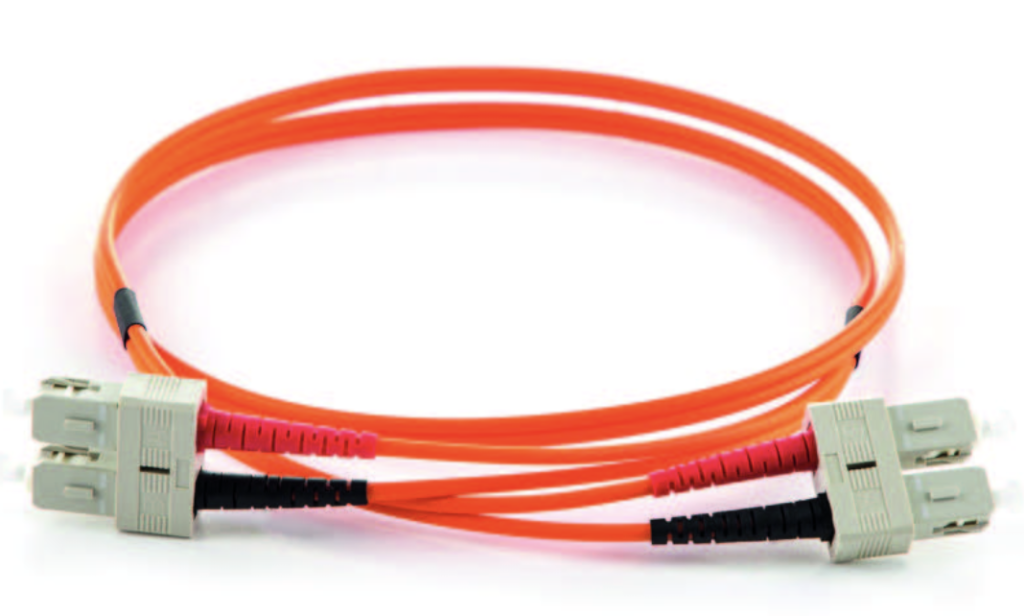

OM2 50/125 ST-SC Duplex Patch Cord

Our OM2 fibre optic cable is for 1Gb/s networks in LAN applications and 10Gb/s applications over shorter distances.

This cable comes with an orange LSZH (low smoke, zero halogen) cable jacket as standard, but it is available in other colours upon request.

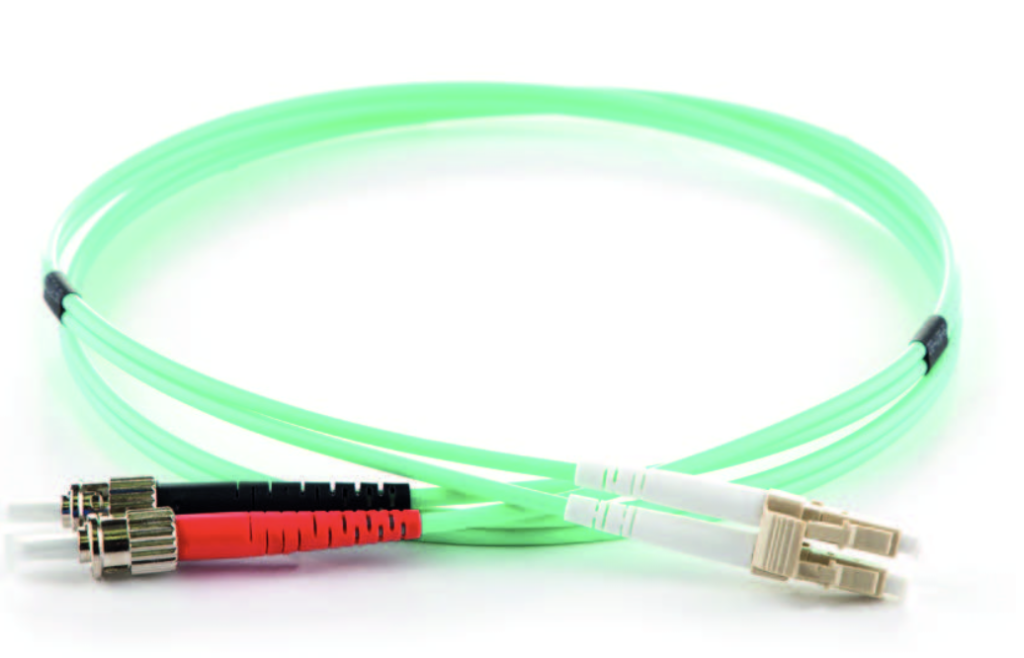

OM3 50/125 LC-ST Duplex Patch Cord

Our OM3 fibre optic cable is for 1Gb/s, 10Gb/s, and higher bandwidth applications over shorter distances, such as those for data centres.

This cable has an aqua LSZH (low smoke, zero halogen) cable jacket as standard; however, as with the previous cables mentioned, it is available in other colours.

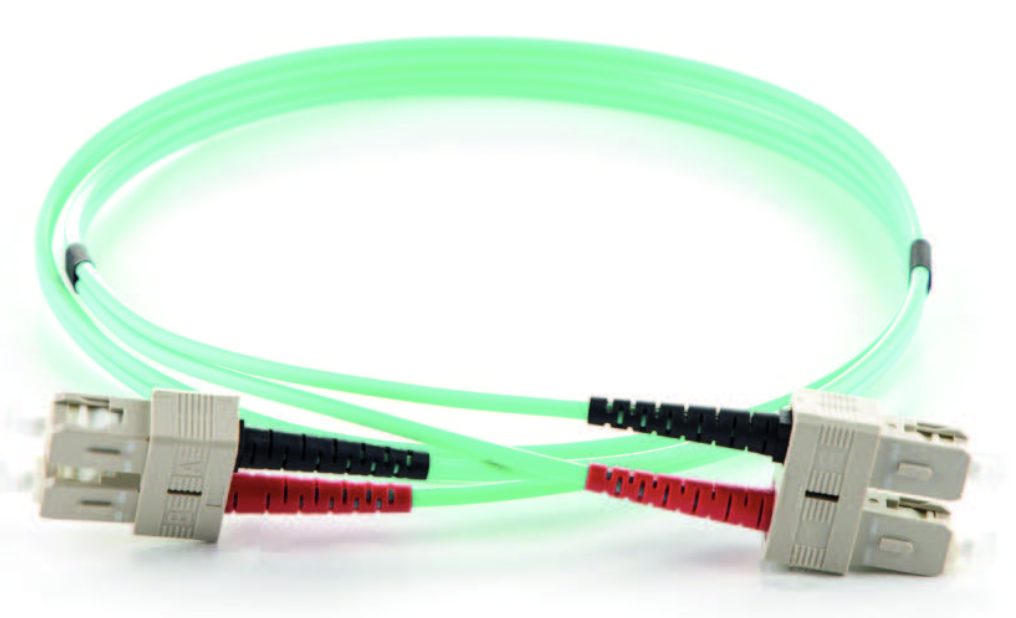

OM4 50/125 SC-SC Duplex Patch Cord

The OM4 fibre optic cable is primarily employed in 10, 40, and 100 Gb/s applications, where increased bandwidth demands and longer transmission distances necessitate a more cost-effective yet high-performance multimode system.

We supply this cable with an aqua LSZH (low smoke, zero halogen) cable jacket as standard, but it is available in other colours upon request.

OM5 50/125 SC-ST Duplex Multimode Patch Cord

Our OM5 fibre optic cable is typically for 10, 40, and 100Gb/s applications over shorter distances.

This cable has a lime green LSZH (low smoke, zero halogen) cable jacket as standard, but we can supply it in other colours.

Get in touch with Altimex today

Now you understand the types of fibre cables you should use to ensure you’re meeting fire regulations according to the installation location.

You should also now understand installation requirements as stipulated in the IEC/CEI standards, to mitigate fires, accidents, and deaths caused by them.

However, contact us today if you have any questions regarding our low-smoke or halogen-free cables. We pride ourselves on supplying fire-safe cables suitable for a range of applications.