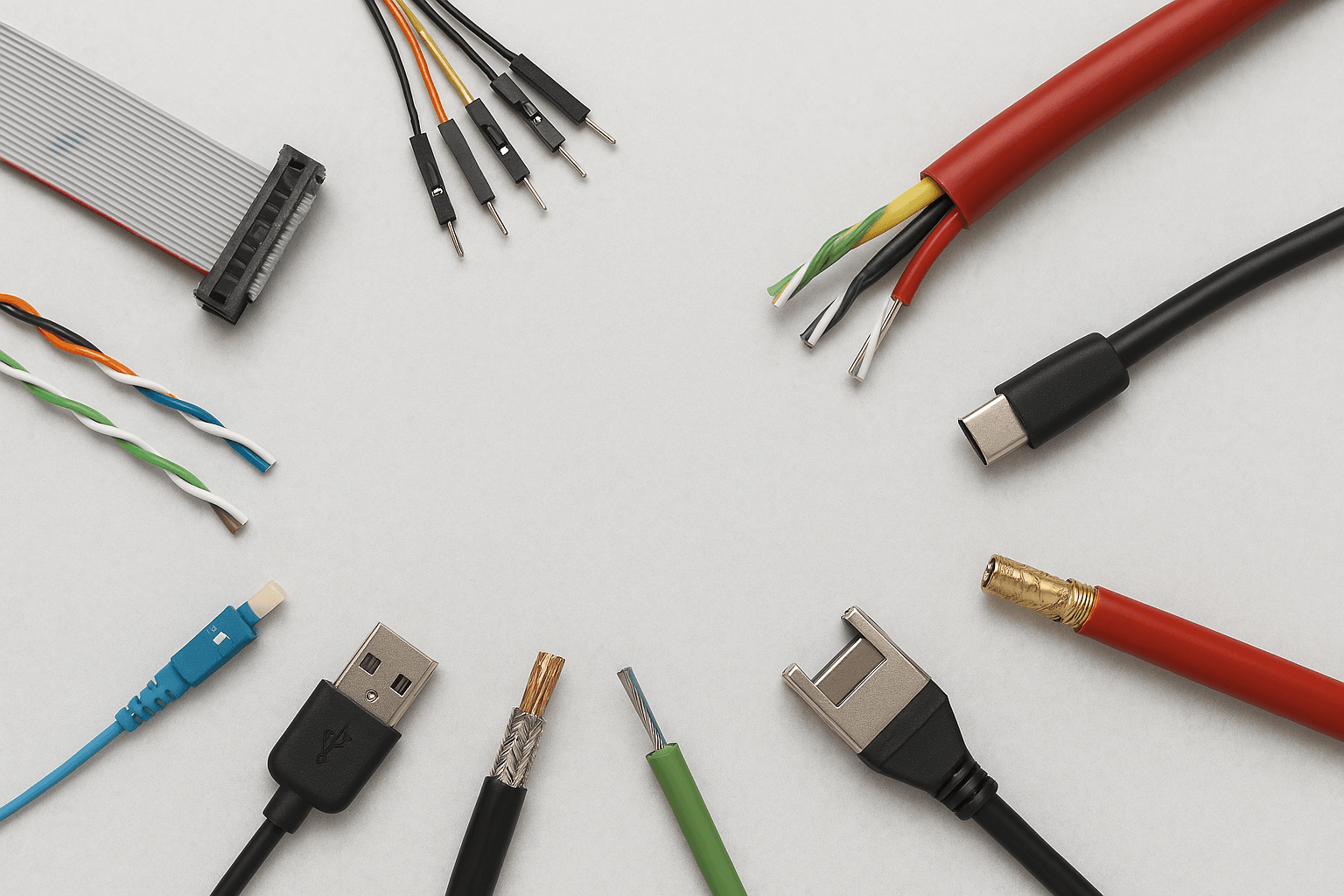

What is Interconnect?

We are proud to introduce our new interconnect cable service, designed to meet the growing demands of industries requiring high-performance connectivity.

Leveraging on our expertise in electronics, fibre optics and lighting, we provide comprehensive cable assembly solutions tailored to meet your unique needs.

Interested In Interconnect Cabling Systems?

Get in touch with us and a member of our team will reach out to you.

Either use the contact form on our website or call us on +44 1829 741262

LVDS Assemblies

We specialise in high-quality LVDS assemblies designed to deliver superior performance in data transmission for a wide range of industries.

Our LVDS assemblies are made to ensure reliable, high-speed signal transfer while minimising electromagnetic interference, which is essential for applications requiring high bandwidth and low power consumption.

Whether you are working in the telecommunications, automotive or medical sector, our cables are engineered to meet industry standards and provide long-lasting, durable connections.

COAX Cabling Systems

COAX cable assemblies are the ultimate solution for your high-quality frequency signal transmission needs. Whether you’re powering up your 5G network, enhancing your home entertainment system or optimising your industrial communications, our COAX assemblies deliver the reliability and efficiency you require.

With their high bandwidth capabilities and durability, these cables are designed to withstand harsh conditions while maintaining crystal-clear signal quality. Experience the difference with our custom length options, allowing for seamless integration into any setup.

Why You Should Work With Interconnect

Quick Turnaround

High Quality

UK Based Manufacturing

30 Years Experience

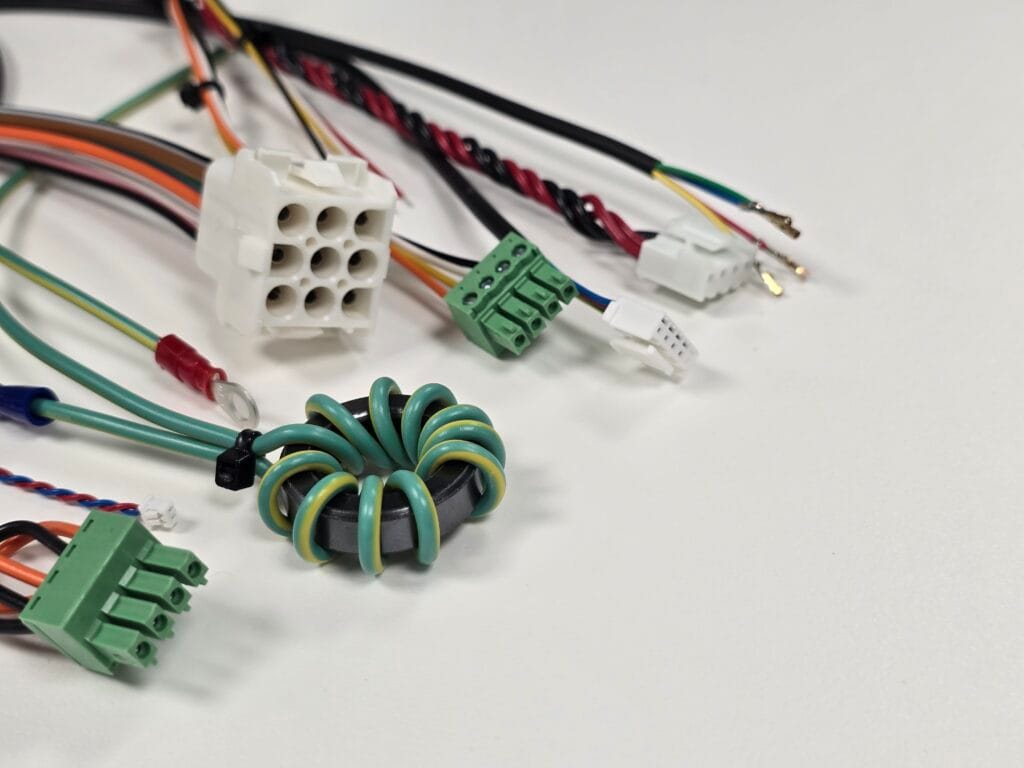

Molex Cable Assemblies

Our Molex assemblies are engineered to provide secure, high-speed connections that ensure optimal signal integrity, even in the most complex and compact systems. Whether your require board-to-board, cable-to-board or wire-to-board configurations, our assemblies are fully customisable to meet your specific requirements.

Built to handle high currents, provide robust protection against electromagnetic interference and operate in challenging environments, our Molex cable assemblies are made from high-quality materials that ensure durability and long-term performance.

Military Circular Cable

We offer military circular cable assemblies, designed to meet the demands of military and defence applications. These high-performance cables are built to provide exceptional durability, reliability and signal integrity in the most challenging environments.

Crafted to meet standards such as MIL-DTL-38999, our assemblies are engineered with precision, offering superior shielding, corrosion resistance and performance under pressure.

Why Work With Altimex?

Industry Specific Solutions

Rapid Prototyping

and Production

Building Long-Term Partnerships

Certified & Experienced Team

IDC Cable Assemblies

Our IDC cable assemblies are designed to streamline the connection process by eliminating the need for traditional wire stripping, reducing installation time and improving overall cost-effectiveness.

Ideal for industries such as telecommunications, consumer electronics, automotive and industrial automation, our IDC interconnects provide excellent performance in high-density, space-constrained environments.

With a wide range of customisable options, such as cable lengths, connector types and pin configurations, we can tailor our IDC interconnects to meet the specific requirements of your project.

BNC Cable Assemblies

Our BNC cable assemblies are designed with precision to deliver secure, robust connections for video, audio and data applications, ensuring optimal signal integrity. Ideal for use in fields such as broadcasting, security systems, test equipment and medical devices, our BNC cables are built to handle both high-frequency signals and environments where durability is key.

Available in a wide range of configurations, including both standard and custom lengths, our BNC interconnects come with a different connector options and we offer configurations that include single and double shielding for superior performance in environments with significant electromagnetic interference.

Over 25 years in the industry.

From manufacturing and providing multiple electronic designs as well as fibre optics, Altimex consistently delivers high-quality award-winning solutions.

- Award Winning Team

- Industry Leading Experts

- Quality one-stop solutions for all

Header/Socket Cutting

Header/socket cutting is a critical step in producing high-quality interconnect cable assemblies. Our advanced cutting technology ensures that each header and socket is accurately trimmed to the desired length, providing a perfect fit for your specific application.

Whether we are working with single or double-row headers, our skilled team uses state-of-the-art equipment to achieve clean, consistent cuts that meet the highest industry standards. This process ensures reliable connections and smooth assembly, preventing issues like poor electrical contact or difficulty fitting connectors into their respective slots.

Standard D-Type Looms

Our BNC cable assemblies are designed with precision to deliver secure, robust connections for video, audio and data applications, ensuring optimal signal integrity. Ideal for use in fields such as broadcasting, security systems, test equipment and medical devices, our BNC cables are built to handle both high-frequency signals and environments where durability is key.

Available in a wide range of configurations, including both standard and custom lengths, our BNC interconnects come with a different connector options and we offer configurations that include single and double shielding for superior performance in environments with significant electromagnetic interference.

Proud to have worked with

Precision Twisting

Precision twisting is a critical part of our interconnect cable assembly process, ensuring that each cable performs optimally in even the most demanding applications.

This technique involves carefully twisting the individual wires within a cable to create a tight, secure configuration that improves signal integrity and reduces electromagnetic interference.

Precision twisting also helps to enhance the durability of the cables, minimising the risk of wire fatigue, breakage, or signal degradation over time.

Get In Touch Today For Interconnect Cable Assemblies

If you have a query about our services or feel like we could help you, please get in touch by filling the form out below or by calling us on 01829 741 262.

Frequently Asked Questions

Interconnect cables serve as the vital links between electronic components, enabling the transfer of signals, power, or data across devices. They ensure seamless communication in systems ranging from consumer electronics to industrial machinery. Depending on the application, they can carry high-frequency signals, power supply, or complex data streams. Their design varies based on shielding, connector type, and environmental resistance, ensuring reliable performance even in demanding conditions like automotive, aerospace, or medical settings.

Shielding in interconnect cables is critical for maintaining signal integrity by preventing electromagnetic interference (EMI) from affecting the transmission. A shield acts as a barrier, absorbing and redirecting noise from external sources such as motors, radio waves, or nearby cables. This is especially important in high-speed or sensitive applications, where even minor interference can lead to data loss or performance issues. Shielding methods include foil, braid, or a combination, with each offering varying levels of protection depending on the specific application.

Impedance matching is vital in ensuring efficient signal transmission without reflections or losses. When the impedance of a cable matches that of the devices it connects, signals can travel smoothly with minimal distortion. Mismatched impedance can lead to signal degradation, echo effects, or loss of data, particularly in high-frequency or digital applications. This is crucial in sectors like broadcasting, telecommunications, or computing, where precision and clarity of signal are paramount for performance and reliability.

When selecting interconnect cables for challenging environments, factors like temperature resistance, waterproofing, chemical exposure, and mechanical stress must be evaluated. Materials used for insulation and jacketing should withstand heat, moisture, or corrosive elements. Connectors must be robust, secure, and sometimes sealed to prevent ingress of dust or liquids. Strain relief and flexibility are also important to prevent damage under constant motion or vibration. These considerations ensure long-term durability and operational reliability.

Twisted-pair cables consist of two conductors wound around each other to reduce electromagnetic interference (EMI). The twisting causes external interference to impact both wires equally, allowing the receiving end to cancel out the noise through differential signalling. This design is particularly useful for transmitting data over long distances or in environments with high electrical noise. The precision and consistency of the twist can significantly influence performance, especially in high-speed digital or communication systems.

Yes, some interconnect cables are specifically designed to carry both power and data simultaneously. These cables streamline system architecture by reducing the number of required connections. This is commonly used in applications like sensor systems, LED lighting, or compact embedded devices. However, it is important to ensure the cable is rated for the required voltage and current levels, and that shielding or internal layout prevents data signal degradation from power line interference. Proper selection improves efficiency and reduces installation complexity.

The quality of cable assembly can directly influence a system’s reliability, signal quality, and overall performance. Poorly assembled cables might introduce noise, resistance, or signal loss. Proper stripping, crimping, and soldering techniques ensure strong connections and longevity. Additionally, appropriate strain relief and shielding techniques help maintain signal integrity and physical durability. In critical applications like aerospace or medical devices, professionally assembled cables reduce the risk of failure, ensuring consistent and predictable system behaviour.