Many people choose to have fibre optics installed within their homes or workplace. However, installing fibre optic cables isn’t easy, so we have devised these tips to help guide you through an installation.

But first, let’s explain why fibre optics have become so popular.

Fibre optics effectively boost a network’s performance, improving its speed and bandwidth, which allows for more productivity. These are particularly useful in industries that offer specific services, such as telecommunications and networks.

However, you should handle it carefully due to the fibre optics’ fragility. Additionally, fibre optics are expensive, making it even more vital that the installation stage is correct to reduce the likelihood of damage.

1) Check regulations

Before beginning a fibre optic installation, check the local and national standards, as they can differ depending on location.

Also, the environment or industry can alter how you follow installation procedures.

2) Create a detailed plan

This step will help you to avoid mistakes.

You should:

- Assess the route looking for any potential hazards.

- Plan where you will lay and connect each cable, including specific information, such as the name of the ports, patch panels, location of network cabinets, etc. This will help you later because if there is a network issue you can identify the node quickly.

- Ensure you have a sufficiently long enough cable for the job.

- Write a list of the equipment and data forms you may need.

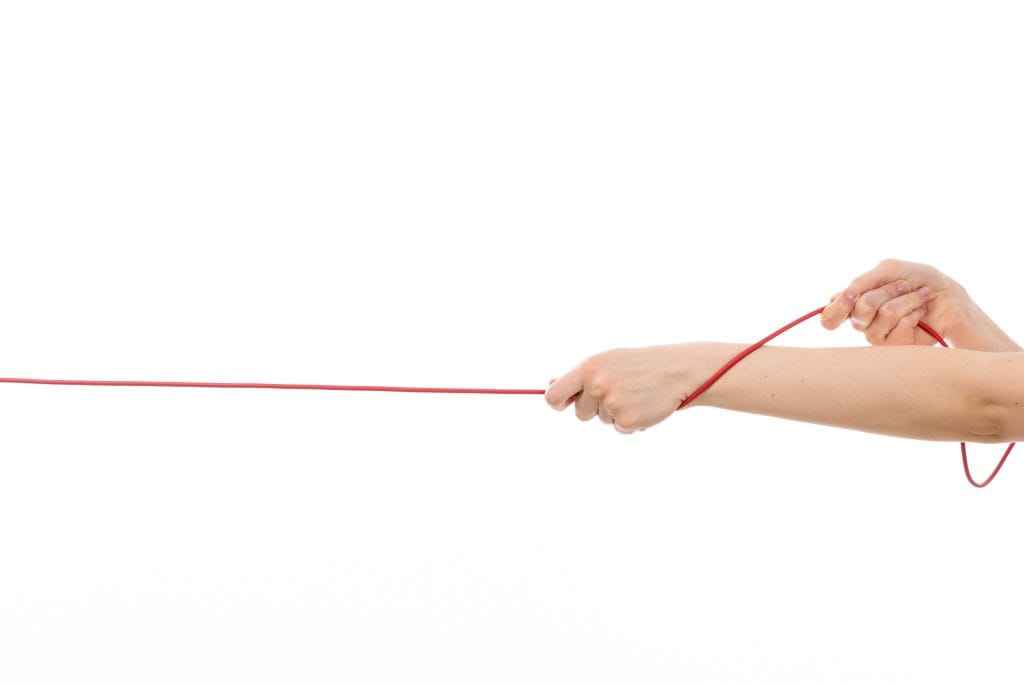

3) Do not pull on the fibre

As previously mentioned, fibre optics are fragile, so avoid handling them unnecessarily. Instead, if you need to manoeuvre the cable, pull on the fibreglass rod.

A fibreglass rod runs the length of the cable, acting as a strength member. The strength member gives the cable added protection, improving its longevity.

4) Do not exceed the cable bend radius

Fibre optics consist of thin strands of material, typically glass, meaning that if handled without care, they can easily break, shortening the cable’s lifespan. This is why fibre optic cables have a minimum bend radius.

The minimum bend radius of a fibre optic cable is as follows:

- Under tension – 20 times the diameter of the cable.

For example, in a cable with a 2mm outer jacket, the bend radius is 2mm x 20 = 40mm.

- Not under tension – 10 times the diameter of the cable.

For example, in a cable with a 2mm outer jacket, the bend radius is 2mm x 10 = 20mm.

5) Support the cable

Another factor that can result in fibre optic cables breaking is if they are installed without any support in place.

For example, if the cable is left naked on the ground, floor, or wall, then it will be exposed to various hazards, making it likely that damage to the fibre optics will occur.

To prevent the above, you should use conduits.

Conduits are flexible tubing surrounding individual fibre strands to help protect them against sharp objects and stress.

6) Apply a lubricant

It may be impossible to avoid bending your optical fibre cable or running it over a long distance, so breakages are likely to occur.

However, if you apply a lubricant at the cable/conduit points, then this will reduce friction and pull load, which, in turn, diminishes the likelihood of breakages.

The lubricant you use must be compatible with the fibre optic cable jacket.

7) Don’t mix fibre optics

If you mix fibre optics, i.e. use single-mode and multimode fibre optics, then this will affect the performance of the cable, or it may not work at all.

Single-mode fibre (SMF) is designed to spread a single light mode, meaning light travels down a single path. In contrast, multimode fibre (MMF) allows for multiple light modes, allowing light to travel down several paths simultaneously.

8) Don’t exceed the maximum pulling load rating

The maximum pulling force of a fibre optic cable is usually 600 pounds for outdoor installations and 300 pounds for indoor installations.

If you have to run the cable over a long distance, ensure that you pull from the middle using an automated puller with tension control. Avoid jerking the fibre optic cable, which can easily break the glass fibres.

9) Roll the cable off the spool

Ensure that you always roll the cable off the spool versus spinning it. Spinning the spool will twist the cable putting stress on the fibres and breaking them.

10) Monitor and communicate

You must monitor the cable, particularly on long runs, and communicate with the rest of the crew during the installation.

Ideally, one person should monitor the pulling equipment, one should monitor the supply reel, and one should coordinate the installation.

If you require any fibre optic services or want to understand more about the various equipment used, such as fibre patch cords, then contact us today.