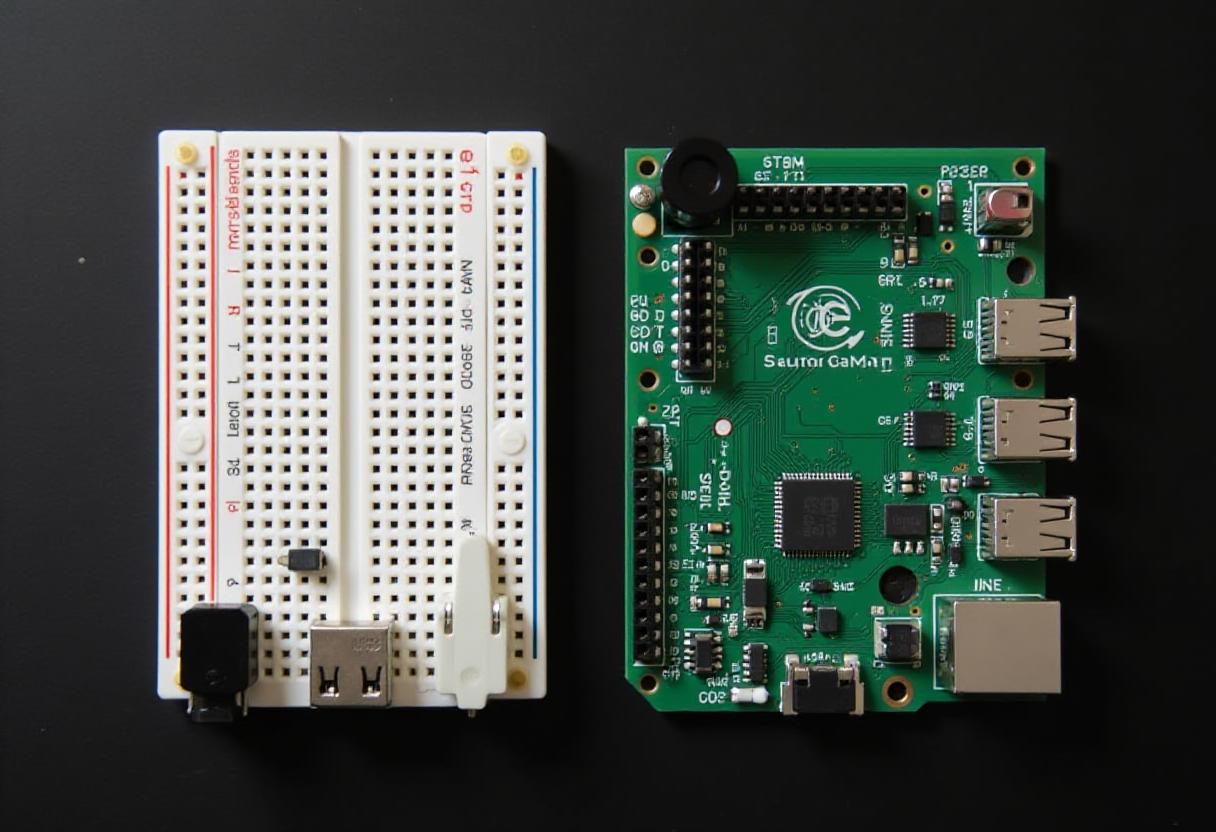

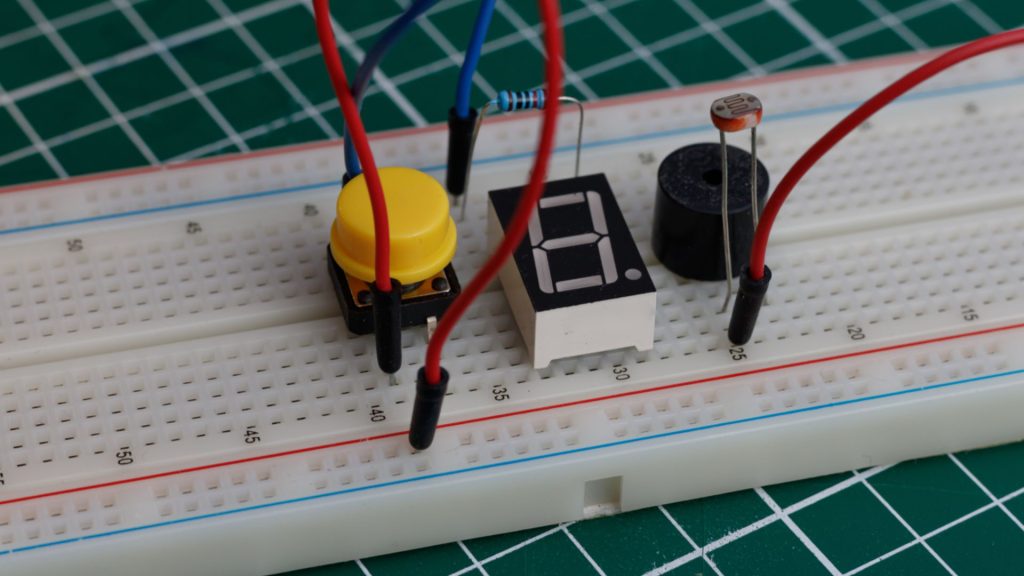

When working on electronics projects, choosing between a breadboard and a PCB is crucial. Breadboards offer flexibility and ease of use, making them perfect for quick prototyping and educational purposes.

On the other hand, PCBs are essential for durable, complex, and final product designs.

For more insights into electronic manufacturing, this article compares the two tools, helping you decide which is best suited for your project needs.

Definition and Uses

Breadboards are temporary, reusable platforms used to build and test electronic circuits without soldering.

Breadboards, originally simple wooden boards with nails for circuit assembly, have evolved into the plastic, solder-free versions used today for quick prototyping.

PCBs, first developed in the 1930s, quickly became essential for durable and compact electronic designs, marking a significant advancement in electronics manufacturing.

They are commonly used in educational settings and by hobbyists for experimenting with circuit designs.

These consist of a grid of interconnected holes where components and wires can be easily inserted and moved.

PCBs are designed to permanently hold and connect electronic components through etched copper pathways.

PCBs are widely used in consumer electronics, industrial applications, and professional projects. They provide a durable, reliable solution for creating complex and compact electronic circuits.

Both these and PCBs are tools in electronics prototyping and final product development.

Breadboards are ideal for quickly assembling and modifying circuits, while PCBs are used for creating stable, long-lasting electronic products.

Understanding when to use each tool is essential for efficient project development.

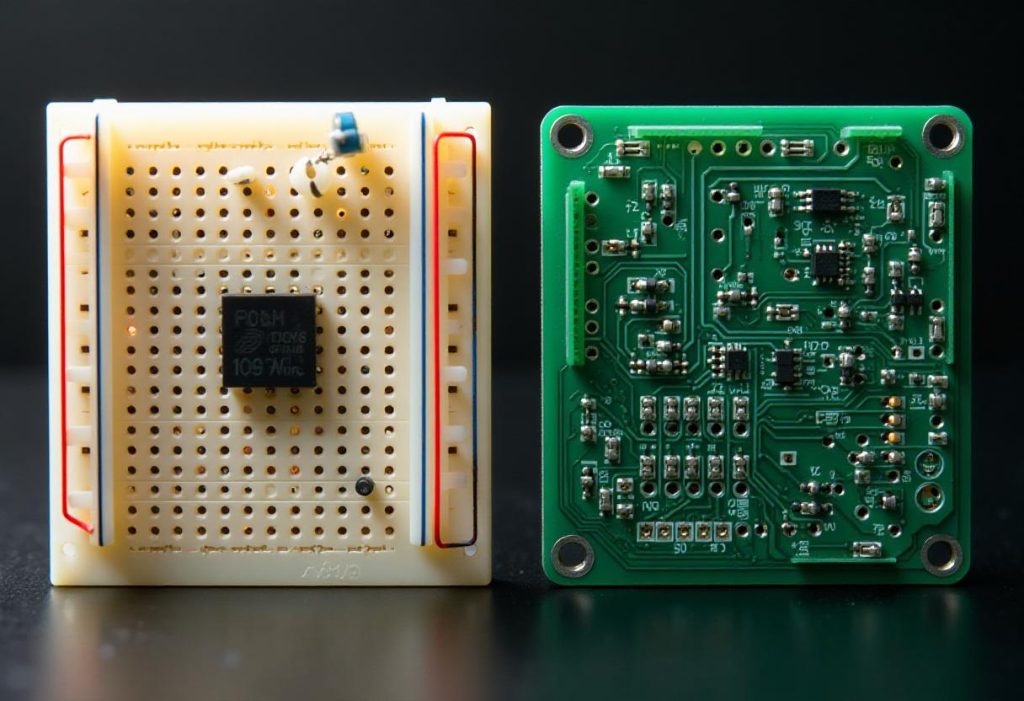

Basic Components and Structure

A breadboard consists of a grid of holes arranged in rows and columns.

The holes are connected internally in a pattern that allows electronic components to be inserted and interconnected without soldering.

These typically have two main areas: the terminal strips, where most components are placed, and the bus strips, which provide power and ground connections.

This structure makes them flexible and easy to use for various circuit designs.

PCBs, on the other hand, are made of a non-conductive substrate, usually fibreglass, with copper traces etched onto the surface to create pathways for electrical signals.

Components are soldered onto the PCB, creating permanent connections. The structure of a PCB includes layers for different functions, such as power, ground, and signal routing.

PCBs come in various sizes and configurations, including single-layer, double-layer, and multi-layer boards, allowing for more complex and compact designs.

Advantages of Breadboards

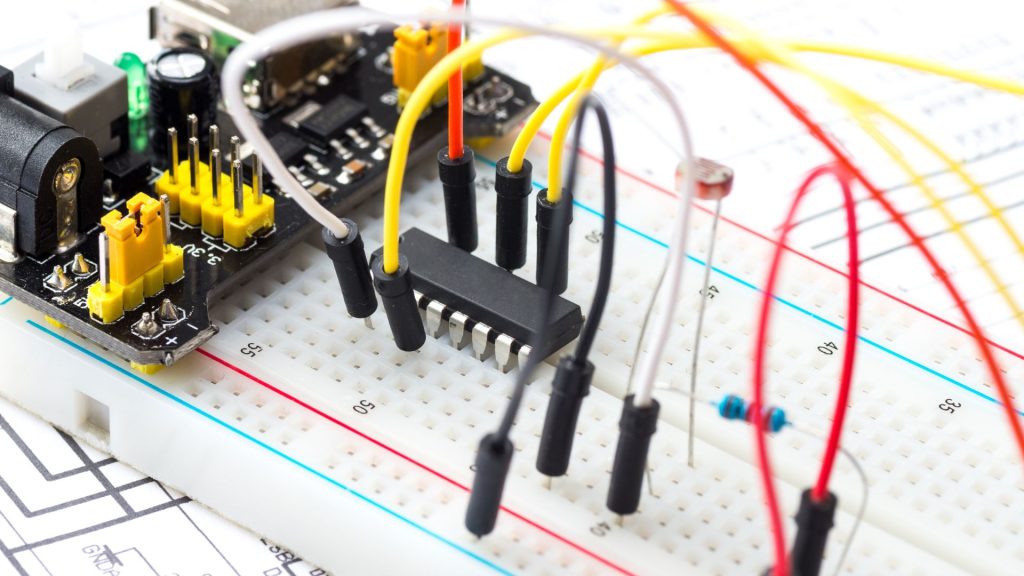

Ease of Use

These allow for easy insertion and removal of components without the need for soldering, making them beginner-friendly.

This simplicity enables users to quickly assemble and modify circuits with minimal tools. For instance, a simple LED circuit can be set up in minutes.

A beginner can easily experiment with different resistor values in a simple LED circuit on a breadboard, making it ideal for learning without soldering.

Reusability

They can be reused for multiple projects, providing an environmentally friendly option.

Unlike PCBs, which are typically single-use, these can be cleared and repurposed, reducing waste and cost.

Proper maintenance, such as careful insertion and removal of components, can extend the lifespan of the product.

Quick Prototyping

They speed up the initial design phase by allowing for rapid experimentation and idea testing.

Adjustments can be made easily, facilitating iterative design processes.

Compared to the time-consuming process of designing and manufacturing a PCB, these boards offer immediate setup and flexibility, ideal for early-stage development and troubleshooting.

University students can rapidly assemble and adjust sensor circuits on breadboards, enabling immediate hands-on learning and feedback.

Disadvantages of Breadboards:

Limited Durability

They can suffer from wear and tear over time.

Repeated insertion and removal of components can loosen the connections, leading to unreliable performance.

Unlike the solid connections of a PCB, these board connections may degrade, especially in frequently used areas.

A hobbyist may encounter intermittent faults in complex home automation projects due to loose connections on a breadboard over time.

Higher Risk of Loose Connections

Loose wires and components are common issues with breadboards, causing intermittent connections.

These unstable connections can lead to circuit malfunctions, making them less reliable for long-term use.

Troubleshooting these issues can be time-consuming and may affect the accuracy of your experiments.

Not Suitable for Complex Designs

They are also limited in their ability to handle high-density and complex circuits.

Organising numerous components can be challenging, leading to messy and confusing setups.

This limitation makes them less suitable for intricate designs that require precise and compact layouts, unlike the neat organisation provided by PCBs.

Automotive engine control units rely on multi-layer PCBs for managing complex functions, where reliability and compact design are crucial.

Advantages of PCBs

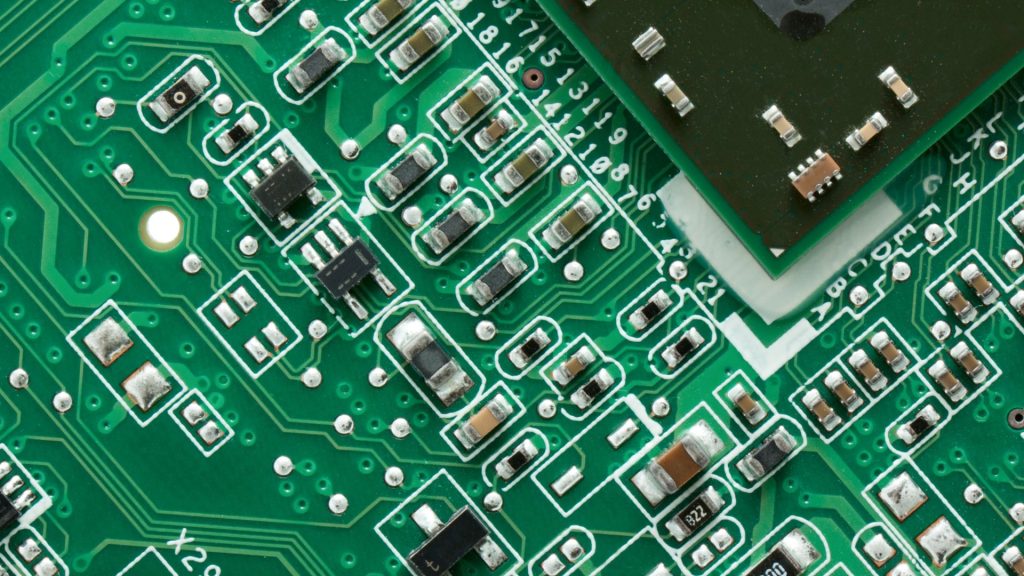

Durability and Reliability

PCBs provide long-lasting connections through soldered joints.

This durability results in reliable performance over time, even in demanding environments.

Industrial applications, for example, often rely on their stability and the longevity of them for various operations.

Compact and Neat Design

They enable the creation of compact circuit designs, allowing for efficient use of space.

The organised layout of components and traces on a PCB improves both the aesthetic and practical aspects of a project.

In contrast to the often messy appearance of breadboarded circuits, these offer a clean and professional finish, suitable for final products.

Suitable for Complex and High-Density Circuits

They also excel in handling complex and high-density circuit designs.

They can support multiple layers and intricate routing, making them ideal for advanced electronics.

High-frequency and high-power circuits benefit from the precise and stable connections that they provide, which are essential for reliable operation.

For instance, multi-layer versions they are commonly used in sophisticated devices like smartphones and computers.

Disadvantages of PCBs

Higher Initial Cost

The upfront costs of designing and manufacturing these products are higher compared to breadboards.

This includes the expenses for custom design, production, and assembly. For one-off projects or small runs, these costs can be significant.

Longer Development Time

Creating a PCB involves several steps, including design, fabrication, and assembly, which can be time-consuming.

Unlike breadboards, which can be set up immediately, these require careful planning and preparation.

This extended timeline can impact project schedules and deadlines.

Less Flexibility for Changes

Once a PCB is manufactured, making changes can be difficult and costly.

Adjustments often require redesigning and producing a new board, unlike breadboards where modifications can be done easily and quickly.

This lack of flexibility necessitates careful design and consideration before committing to a PCB.

Discovering a design flaw in a PCB during final product development can lead to costly and time-consuming rework, unlike the flexibility of breadboards.

Cost Comparison

Initial Investment

Breadboards require minimal initial investment, making them accessible for hobbyists and small projects.

The cost of setting up a board is relatively low compared to the expenses involved in designing and manufacturing a PCB.

This makes them a budget-friendly option for prototyping and educational purposes.

Cost Efficiency in Production

PCBs offer cost benefits in mass production.

While the initial setup costs are higher, the per-unit cost decreases significantly with large production runs.

This makes PCBs more economical for commercial products and large-scale manufacturing, where consistency and quality control are required.

The comparison between breadboard and PCB highlights the need to choose based on project scale and budget considerations.

When to Use a Breadboard

Prototyping and Testing

These are ideal for the initial design and testing phases of a project.

Their flexibility allows for quick changes and adjustments, making them perfect for experimenting with new ideas.

They are also beneficial for troubleshooting and iterating on designs before committing to a final layout.

Educational Purposes

They are widely used in educational settings to teach basic electronics and circuit design.

If you compare pcb board vs a breadboard the latter provides a hands-on learning experience, allowing students to easily understand and visualise circuit connections.

This makes them an essential tool in classrooms and for self-learners.

When to Use a PCB

Final Product Development

These are essential for transitioning from a prototype to a final product.

They provide a stable and reliable platform for electronic components, supporting long-term performance.

They are used in the production of commercial and industrial products, where durability and precision are required.

Mass Production

They are highly beneficial in large-scale manufacturing.

They offer cost and efficiency advantages, making them ideal for products produced in large quantities.

Consistency and quality control are easier to maintain with PCBs, which is needed for the reliability of each unit in mass production.

Both breadboards and PCBs serve distinct purposes in the field of electronics.

Breadboards are invaluable for prototyping, testing, and educational purposes, offering flexibility and ease of use.

On the other hand, PCBs are essential for final product development and mass production, providing durability, reliability, and efficient use of space.

Both breadboards and PCBs serve important roles in electronics design. Breadboards are ideal for prototyping and educational projects where flexibility and ease of use are paramount.

In contrast, PCBs are the go-to choice for final products that require durability and precision.

By understanding the strengths and limitations of each, you can choose the right tool for your specific project, ensuring successful outcomes. For further assistance or to discuss your project needs, contact us.