Fibre optics are used in various industries today. With modern dependencies on fast internet speeds and instant download capabilities, fibre optic cables can help businesses remain productive in our current digital age.

However, considering how much we need this technology in our personal and professional lives, how much do you know about fibre optics? How have they developed into the cables we know and use today? What can we use them for, and what variations are available?

Fibre optic cables have numerous applications within our society, from our telecommunications to our medical equipment, to name a few. They also offer many benefits to their users.

This guide delves into all the information you need about fibre optic cables, including their extensive history, how to maintain them and how they can support your technological needs.

But first, we need to establish what a fibre optic cable is.

What is a Fibre Optic Cable?

Fibre optics cabling transmits data using light through strands of plastic or glass. A strand is slightly thicker than human hair, and an insulated case surrounds it.

There is a transparent core in each strand encased in glass cladding. The core transmits the light, whereas the cladding reflects the light back into the strand to travel along the fibre. This is done by a phenomenon called Total Internal Reflection (TIR).

This cable type can be single-mode or multi-mode. Single-mode cables have smaller cores and lasers are used as the light source and have higher optical powers with narrow bands of wavelength which allows for considerably longer distances.

Multi-mode cables, in contrast, have larger cores and LEDs are used as a light source. Shorter distances as an LED have less optical power with a broadband of wavelengths. They are more likely to suffer signal loss and have less bandwidth than single-mode cables.

This cabling has various types, each better suited to specific applications.

Fibre Optic Cable History

Roman Times – 18th Century

Whilst they are common in modern society, fibre optics can be traced back centuries, with people having drawn glass into fibres as far back as Roman times. However, over 1000 years would pass before the first ‘optical telegraph’ would be created.

In the 1790s, the Chappe brothers created the first ‘optical telegraph’, a method of communication using light on towers. It reduced the time needed to transmit messages because they no longer had to rely on sending them via messengers on horseback.

The history of optical fibre saw multiple experiments in the following years.

19th Century

In the 1840s, Jacques Babinet and Daniel Colladon, two physicists, proved how a person could direct light via jets of water within a fountain display.

A similar demonstration occurred in 1854 when John Tyndall revealed how a light signal could bend and travel around corners using a stream of pouring water.

People credit Alexander Graham Bell for inventing the telephone, but he also patented the ‘photophone’ in 1880. This device was an optical telephone system that transmitted a voice message using light, though its operations depended on various factors, including the weather. He did not continue to research this invention.

Two Viennese doctors, Doctor Reuss and Doctor Roth, applied this information in the medical industry in 1888. They used bent glass rods to illuminate body cavities, specifically the nose and larynx. The medical team were also able to use it in some ophthalmological surgeries.

Early – Mid-20th Century

Over 40 years later, in 1930, Henrich Lamm used multiple optical fibres to transmit an image for the first time, though the picture was of low quality. Lamm based this on the work of Hansell and Baird, who thought about transmitting images using several transparent rods for facsimiles and television, respectively, and patented these ideas in the 1920s.

Lamm was a German medical student and intended to use this technology to look at inaccessible body parts. However, the rise of the Nazi party forced him to move to America. Lamm was unsuccessful in filing a patent due to Hansell’s British patent.

The ‘maser’, which stands for ‘microwave amplification by stimulated emission of radiation’, was created by Charles Townes in 1954 at Columbia University. His and his colleagues’ work fed into the development of the laser, a concept developed by Townes and Arthur Schawlow.

In 1958, the laser was introduced and demonstrated how a person could make the maser work in infrared and optical regions. ‘Laser’ stands for ‘light amplification by stimulated emission of radiation’. It was also an efficient light source.

Elias Snitzer published a theory concerning single-mode fibres in 1961. His theory described fibre that could transmit light with one wave-guide mode. The fibre would have a small core to do this.

Snitzer demonstrated that a person could direct a laser through a thin glass fibre and apply this to medical uses, but at this point, people could not yet use it for communications.

Late 20th Century

By experimenting with fused silica, scientists at Corning Glass Works made single-mode fibres with less than 20dB/km attenuation in 1970. Scientists could lower the attenuation levels a few years later to below 10dB/km.

Standard fibre optic cable manufacturing uses chemical vapour deposition, a process initially used in 1973 and developed by Bell Laboratories. It involves heating oxygen and chemical vapours, which makes ultra-transparent glass. Mass-production of low-loss optical fibre uses this glass.

Two years later, in 1975, Dorset police installed the first non-experimental fibre-optic link.

When companies started rebuilding communication infrastructure in the late 1970s and early 1980s, they used fibre optics. The mid-1980s also contains the creation of Spirit, the first 100% digital fibre optic network company.

In 1986, Emmanuel Desurvire from Bell Laboratories and David Payne from the University of Southampton reduced how much long-distance fibre systems cost. They did this by inventing the erbium-doped fibre amplifier, which meant optical-electrical-optical repeaters were no longer necessary.

An all-optic fibre cable was installed across the Pacific Ocean in 1996. This cable, TPC-5, was the first fibre optic cable that used optical amplifiers across this ocean. A year later, Fibre Optic Link Around the Globe (FLAG) became the primary infrastructure for future Internet applications when it became the longest single-cable network globally.

What are the advantages of Fibre Optic Cables?

Better bandwidth

Cables with higher bandwidths are vital for businesses due to their need to transmit data, and fibre optic cabling can allow a company to do this.

The bandwidth refers to how much data a cable can transfer over a specific timeframe. More data is transmitted with a higher bandwidth.

Fibre optics have a better bandwidth when compared to their copper counterparts. This increased capacity allows data transfer to occur quickly and places fewer restrictions on those transfers concerning volume.

Bandwidth also impacts internet speed (as discussed below), which can affect businesses and their online work.

Faster internet speeds

Due to the better bandwidth of fibre optic cables, they offer faster internet speeds too.

Faster speeds can occur as the photons in fibre optics can travel at the speed of light. The light signals do this for approximately 70% of the transmission journey. In comparison, the electrons in copper cables are transmitted over 100 times slower.

If the internet speed is slow, this can reduce productivity within a business as employees cannot access everything they need for their jobs to run smoothly and efficiently.

Internet and transmission speeds are faster when using fibre optic cabling, making them a good investment for businesses.

Flexible

It is vital that cables can connect to relevant devices with low chances of breakage.

A damaged cable can make the connections unreliable, potentially preventing productivity at home and work when it is data or internet dependent.

Fibre optic cables are flexible and can easily bend, which can help reduce the likelihood of breakage or damage when used. They are also lighter and thinner than copper cables and resist electromagnetic interference.

However, whilst ideal for longer-distance situations or more extreme environments, be aware that glass fibre optics are more fragile than other options. Therefore, other optical fibres, such as plastic cables, may better suit your circumstances.

Strong security

Whilst transferring data, it must remain secure. Fibre optic cables have higher security than their copper equivalent, partially because they do not radiate signals. Therefore, it is hard for someone to tap into the transmission without your knowledge.

This cable type can also bring more security as, unlike metal wires, the electronics and hardware required can all be in one location.

Long-distance transmission

Signal loss occurs during data transmission, though the loss levels vary depending on the cable used. This loss affects the distance over which data transmits using these cables, with less signal loss equalling a more significant distance.

Copper wiring loses approximately 94% signal strength when used over a distance of 100m. On the other hand, fibre optics only lose around 3% over that same distance.

Fibre optic cabling can, therefore, transmit data further and can do so over 10s of kilometres.

Eliminates latency issues

Lower latency is preferred as it takes less time for data to transmit from the source to the final destination. Cable internet usually has higher latency, so it takes longer for videos to be uploaded or downloaded. High-definition content is also affected.

However, fibre optic cabling tends to have lower latency, enabling larger files to be uploaded or downloaded without disruption. It also allows better collaboration between colleagues, making it an invaluable investment for businesses.

What are the different types of Fibre Optic Cables?

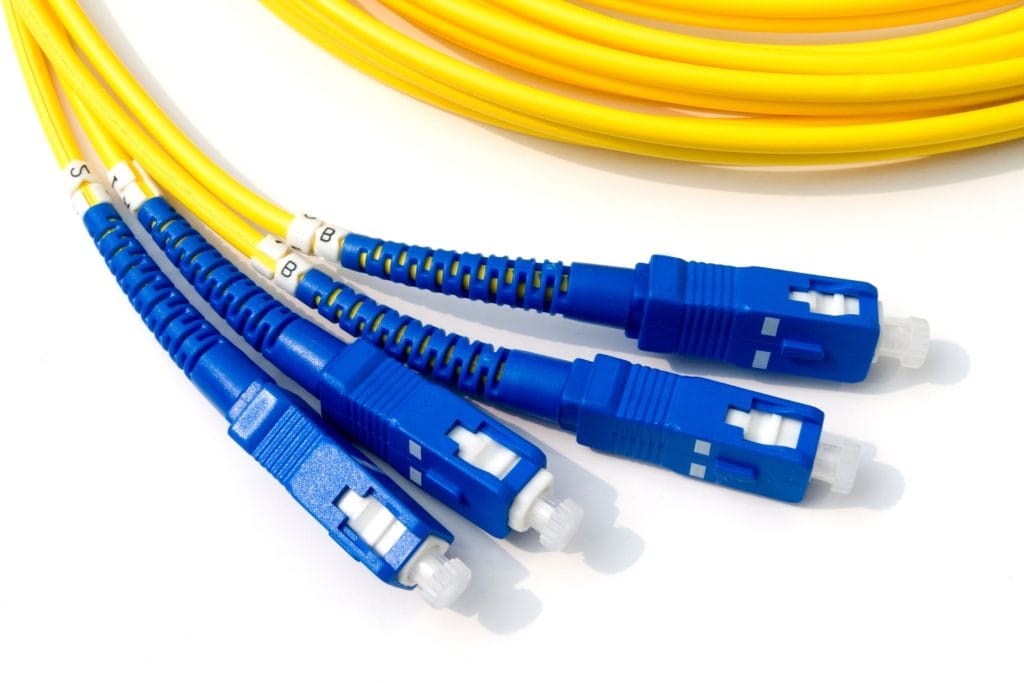

Fibre Patch Cords

This cable type has a fibre optic connector at each end, such as the SC or the LC connector. The connectors then enable the cable to attach to different computing equipment in numerous settings. This makes them ideal for business use, especially when equipment from various workstations needs to be connected.

Fibre patch cords are ideal for indoor use, and single-mode and multi-mode variations are available.

Multi Fibre Assemblies

For those needing several different cables, multi-fibre assemblies are ideal for various purposes instead of just one, which makes them a convenient and cost-effective investment. Two multi-fibre types include tight-buffered pre-terms and breakout pre-terms, which allow people to find the assembly that meets their needs.

If you are looking for multi-fibre assemblies, Altimex manufactures custom cables to suit your individual needs, such as with a fan out or staggered configuration.

Bulk Fibre Cables

When looking at bulk fibre, there are four you can choose from, which are:

- Tight buffered fibre cable

- Universal distribution loose CST cable

- Universal distribution standard loose tube

- Universal standard loose tube cable

These different bulk fibre cables have their individual properties and features, making them more suitable for varying applications.

Both full drums of these cables and ones cut to the required length are available.

Different Types of Fibre Optic Cable Connectors

Fibre optic connections require the correct connector to ensure everything works correctly, and the necessary connector will depend on the equipment you want to use and the optical fibre.

LC Connectors

The lucent connector (LC) is small, making it ideal for situations with limited space. It is approximately half the size of an SC connector and has a ferrule of 1.25mm.

You can find LC connectors used within data centres.

SC Connectors

This connector is used in various circumstances and is the most widely used connector type. The subscriber connector (SC) uses a pull-push motion, which allows it to connect to the cable. The ferrule is 2.5mm, and it is an inexpensive connector to use.

ST Connectors

Straight-tip (ST) connectors are not as commonly used as the SC and LC options but are still used within the military and have industrial uses. Their installation is simple, and they are inexpensive. They also have a 2.5mm ferrule.

FC Connectors

Whilst replaced by the LC and SC connectors in numerous situations due to cost and installation, the ferrule connector (FC) was the first with a ceramic ferrule. It also has a screw-on collet, a feature still favoured in places with high vibration.

Fibre Optic Cable Applications

Each fibre optic cable type has unique features that suit it for different applications. Numerous industries can use them to help with the efficient transfer of data within the business, such as mechanical inspections and vehicle safety features.

If you want more ways to use fibre optics, look at ten uses of optical fibre cables, some of which you may use in your daily routines.

Data centres

This location type requires cables that can fit in small spaces and have high bandwidths. Fibre optic cables for data centres have smaller connectors to squeeze in those tight spaces and allow those data transfers to occur.

Fibre optics also have faster speeds, which can manage the needs of the data centres, such as starting to use speed faster than 100 Gig.

Telecommunications

When communications use fibre optics, they transmit data via signals almost within the infrared part of the electromagnetic spectrum. In some locations, the use of fibre optic cables in this way has replaced the copper ones that were once forming the services.

Telecommunications signals, which are voice and data, are transmitted through these cables. Fibre optics also means electromagnetic interference is less likely, so fewer data will be limited or lost.

Telecommunications commonly use single-mode fibre optics.

Internet

Whilst Ethernet cables can provide access to the internet, fibre optic cables tend to be faster, reaching up to 100 Gbps, and extend over long distances. As they also usually have higher bandwidth, fibre optics are an ideal broadband cable for companies requiring large amounts of data transferred simultaneously.

Fibre optic cables offer a more reliable internet connection. Weather doesn’t impact these cables, so data transfers can continue whilst disruptions may occur using Ethernet cables in the same conditions.

The internet tends to use single-mode fibre cables.

Cable television

As a cheaper alternative to their copper counterparts, fibre optic cables are ideal for cable television. Their higher bandwidth also helps transmit signals to high-definition televisions.

Fibre optics can provide a better picture on the television, and the cables can reach further when installed. It is common to find single-mode fibres used for cable television.

Medical equipment

With the evolution of medicine and its technological developments, an early form of fibre optics was used in this field as a light for body cavities in 1888. The cable has since developed various applications. Procedures such as endoscopies utilise them to illuminate inside the body. They can assist with the likes of keyhole surgeries and the diagnoses of diseases.

Numerous imaging processes, such as computerised tomography (CT) scans, use fibre optics. CT scans use X-ray imaging to form a 3D image of the body, which medical staff can use to help a patient.

How to Install Fibre Optic Cables

There are various fibre optic installation tips to reduce the chances of damaging the cables. Whilst flexible, they can still become broken and require replacing before you can use them, so ensuring you get the installation process right is essential.

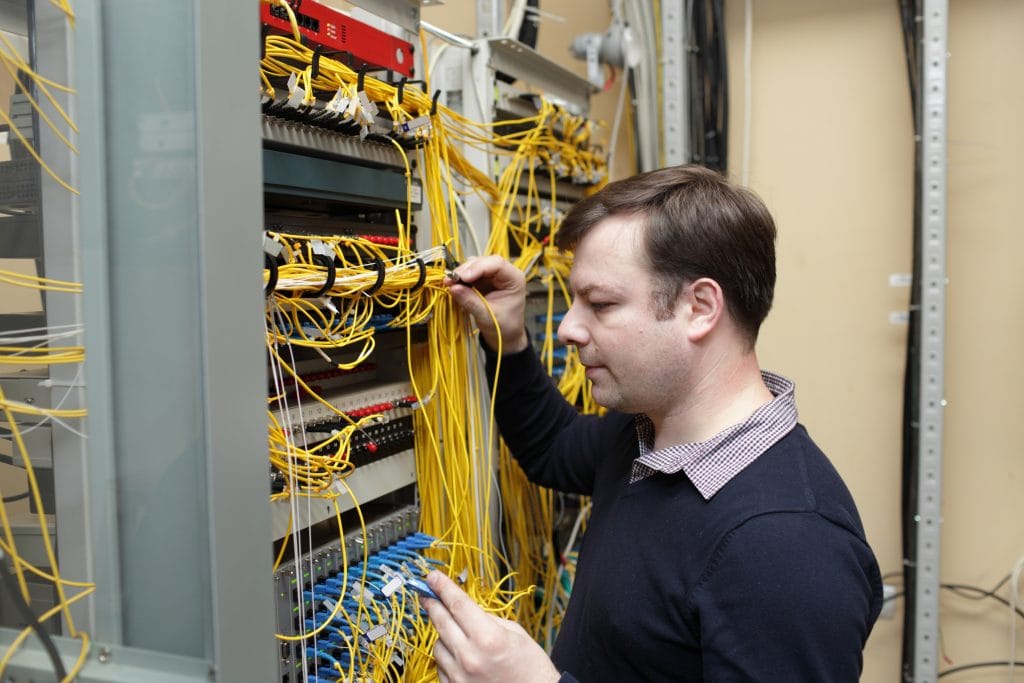

Only fully-trained professionals should install fibre optic cables. Usually, a network engineer does this.

Pre-installation planning

When you want to install fibre optic cables, planning is crucial to ensure the final workings of the fibre optics are reliable. The network engineer inspects the area and available deployment routes to make the installation effective.

This preparation can include various elements, such as site terrain inspections, site surveys and engineering plan submission, to name a few.

The planning can also make the installation quicker.

Cable preparation

A professional needs to prepare the fibre optic cable before splicing it. Therefore, they must remove a section of the multiple layers protecting the fibre. These layers include the following:

- The coating – a thicker layer of plastic around the cladding

- The strengthening fibres – the layer that helps protect the core from installation damage

- The cable jacket – the cable’s outer layer

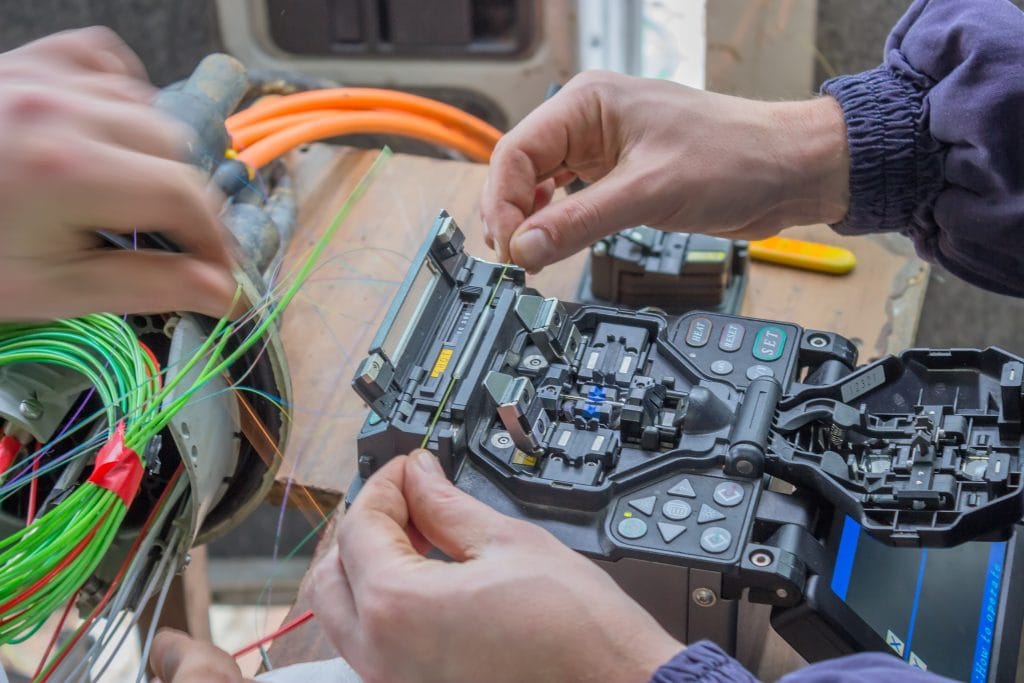

Once exposed, they clean the fibre using alcohol. Then, using a fibre cleaver, they cut the fibre to the specific length required, and it gains a splice protection sleeve.

Splicing and termination

Fibre splicing is the process of joining two separate fibre strands, and there are two different methods to do this. These methods are called mechanical splicing and fusion splicing. For fibre optics, fusion splicing is the more common way.

To fusion splice a cable, it requires a specific fusion splicer machine. After aligning the two fibre ends precisely, an electric arc fuses the two ends. The splice protection sleeve shrinks due to the fusion splicer’s heater. This process attaches the two fibres.

The network engineer installs the fibre optic cable through a termination enclosure, which is also called a “wall box”. If the network engineer installs the cable in a home, the termination enclosure is near the main electrical panel and on the side of the house. A fibre installer can mount it on the wall if the home doesn’t have one.

Usually, the cable is surrounded by a riser pipe when it enters the termination enclosure.

Having the termination enclosure outside means the fibre technician can begin the network diagnostic review for future issues without entering the building.

On the termination enclosure is the optical network terminal, where the installer terminates the cable connection. The optical network terminal converts the light signals in the fibre optic cable into electrical signals.

When the building connects to the optical network terminal, the network can deliver video and the internet, to name a few.

Testing and certification

The final part of fibre optic cable installation is the testing and certifying stage.

At this point in the process, the engineer tests the cable and the connection to ensure everything works properly and reliably. They can conduct various tests to know if the installation is correct and if the equipment has no faults. If there are issues, the tests can help establish where the problems are.

Maintenance of Fibre Optic Cables

Maintaining your fibre optic cables and their connectors is essential for quality connections to be established and maintained. Dust, dirt or other things on the end of the connector can impact the transmitted signal.

Cables that are not maintained properly can also become damaged, such as having scratches on the glass surface. You should treat them with care for this reason.

Therefore, you must know how to clean fibre optic cables to ensure they work correctly and reduce the chance of breakage or damage. Contamination, such as fingerprints and dust, is the primary cause of fibre failure, and an unused cable is not guaranteed to be contamination free.

Please be aware that constant maintenance can damage your cables. Fibre optics are designed so that, after installation, you can leave them alone until there is an issue.

Bending the cable excessively, for example, can cause damage to the different elements in the cable. After resolving a problem, ensure you clean the connectors and cable again.

Cleaning and inspection

Before cleaning fibre optics, ensure you have disconnected the cable at both ends and turned off any laser sources. You should check the connectors before cleaning.

Even new cables need checking to ensure they are as they should be. Unused cables can still have dust or condensation, which can contaminate it, so you must clean the ends before attaching them to a connector.

The first part of the cleaning process is to inspect the fibre optic connector, bulkhead or component. You should use a fiberscope for this. Here you will find what parts of the cable require attention.

You should clean a dirty connector using a dry cleaning technique, followed by a wet cleaning technique, if that doesn’t work. If you use a wet cleaning technique, you must immediately follow it with another dry method.

A dry cleaning technique wipes the end face of a connector with a dry cloth in a single direction using a reel-based cassette cleaner. The cleaner should have medium pressure. You can repeat this at least twice and must clean both parts of the fibre optic.

A wet cleaning technique uses 91% Isopropyl Alcohol or a special fibre optic solution. Again, wipe the connector end face, this time with the wet part of the cloth. The dry cleaning that follows is to remove any residue. You can repeat this step.

During fibre optic cleaning, do not touch the connector end face. You should also wear safety glasses during this process.

Troubleshooting

Various things can cause issues with a fibre optic cable, so professionals use troubleshooting to identify and amend the problem.

The Visual Fault Locator (VFL) is the simplest tool for troubleshooting and uses a visible red laser beam. This beam enables the device to detect breaks within the connectors, splices and cables and to test for continuity. However, the VFL is one of the various tools an engineer can use to identify problems with fibre optics.

An Optical Time Domain Reflectometer (OTDR) is another device, this time used for advanced troubleshooting. It uses the amount of reflected light it can detect to work out signal loss in the cable, and it can locate where issues such as a splice or break are. Whilst an effective tool, they are expensive and require the operator to know their use.

Fibre jumpers are a crucial part of a fibre network but are more likely to suffer damage because they tend to be the weakest and most manipulated parts. If you need to troubleshoot individual fibre jumpers, you can use an optical loss test set (OLTS).

The Future of Fibre Optic Cables

The evolution of fibre optics has developed significantly over the years, and this development is forecasted to continue as the century progresses.

By 2028, it is predicted that the industry’s market size will be worth almost $2,346.69 billion and that it will reach a CAGR of 4.95% between 2022 and 2028. By 2025, it is believed that the integrated network economy will reach $60 trillion, and the fibre optic network market will reach $8.2 billion by 2027.

This type of cable is already in higher demand than in previous years, and fibre optic in the future is sure to become even more popular. Their range of advantages could significantly help their users, and if more fibre optic cables are used globally, more people and businesses will have the opportunity to access its benefits.

Future cables may support even higher speeds than currently available, helping to promote workplace productivity further. Organisations like the IEEE are attempting to achieve this.

Fibre optic cables are helpful for domestic and business purposes with their faster internet speeds, better bandwidths, and the other benefits they offer. They have yet to replace copper cabling entirely at the time of writing. Still, their advantages make them more popular, and they provide a cost-effective solution to our technological needs for the future.

Whilst you may better understand fibre optics after reading this blog, you can still have questions about the cabling and how to incorporate them into your business or home. Altimex is a fibre optics solutions company and electronics manufacturer and can help you with your electronic, lighting and cabling needs.

Whether you want to know more about installing these cables, which cables are available for your circumstances, or want to know more, we are here to help. For more information, contact us with your enquiries and see how we can help you with fibre optics.