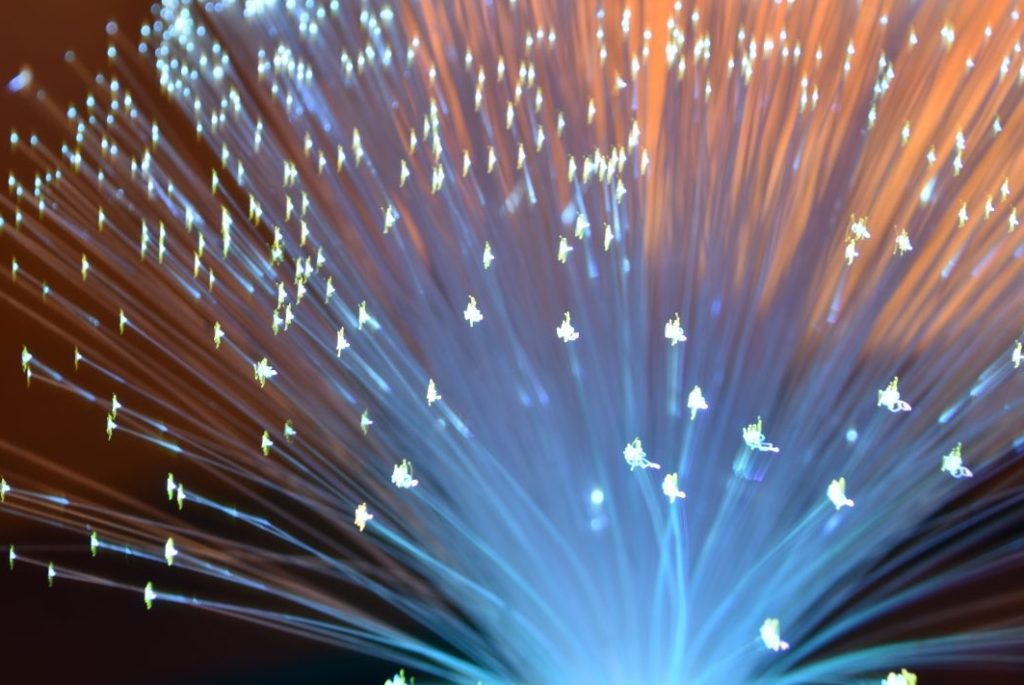

Fibre optic cables are pivotal in the infrastructure of modern telecommunications, providing high-speed data transmission across vast distances with minimal loss.

The termination of these cables is a critical step in installing fibre optics, ensuring they deliver optimal performance and reliability.

This guide aims to demystify the termination process, presenting a step-by-step approach to various methods suited for different applications.

Terminating fibre optic cables correctly is essential for maintaining the integrity of the communication network. This section introduces the primary techniques used in the industry.

1) Connectors

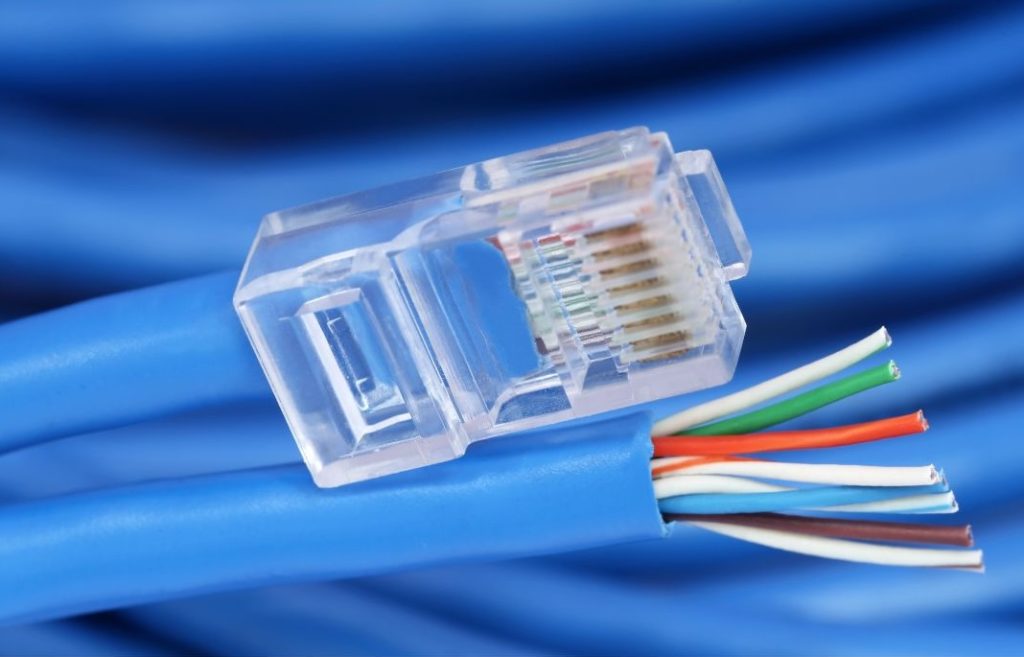

Connectors are fundamental in terminating fibre optic cables, facilitating the connection between cables or devices.

Each connector type is designed with specific applications and performance criteria in mind. The choice of connector depends on various factors, including the physical environment, the type of fibre optic cable (single-mode or multimode), data transmission requirements, and the need for density in connections.

ST and SC connectors are robust, reliable, and suited for a wide range of applications, with SC connectors being slightly preferred for their push-pull design in single-mode applications.

LC and MU connectors are designed for high-density environments where space is at a premium, offering excellent performance in a compact size.

Understanding these differences is crucial for engineers, electricians, and technicians to select the appropriate connector for their specific fibre optic cable installation needs, ensuring optimal performance and reliability of the fibre optic network.

Here are the steps for cable termination using various connectors:

ST Connector

Begin by stripping the cable to expose the fibre, then cleave the fibre to create a flat end. Insert the fibre into the connector and secure it in place.

SC Connector

Similar to the ST connector, prepare the cable by stripping and cleaving. Use a crimp tool to attach the connector, ensuring a tight fit.

LC Connector

Known for its compact design, the LC connector requires careful handling. Strip, cleave, and insert the fibre into the connector, utilising a specialised tool to secure it.

MU Connector

This smaller connector type follows a similar process, with emphasis on precision due to its miniaturised design.

2) Splicing

Splicing is another technique for joining fibre optic cables:

Mechanical Splicing

This method aligns fibres mechanically within a special housing. Clean the fibre ends, align them in the splice unit, and secure them together. This method is quick but slightly less reliable than fusion splicing.

Fusion Splicing

Requires a fusion splicer machine. Strip, clean, and cleave the fibres. The machine then aligns and welds the fibres using an electric arc, ensuring a high-quality join with minimal loss.

3) Multimode Terminations

Multimode fibre terminations require particular attention due to their wider core, which supports multiple light modes.

Ensuring a smooth end-face and accurate alignment is crucial to minimise signal loss and reflection.

4) Hot Melt

The hot melt cable termination method involves pre-loaded adhesive in the connector, activated by heat.

Prepare the fibre by stripping and cleaving. Insert the fibre into the heated connector, which melts the adhesive, securing the fibre upon cooling.

5) Crimping

Crimping is a termination method where a metal sleeve is used to mechanically secure the fibre within the connector.

This process does not involve the use of adhesives or heat, making it a quick and effective solution for certain types of fibre optic cables.

Crimping is especially useful in environments where speed and ease of installation are prioritised.

- Strip the cable to expose the fibre and buffer.

- Insert the fibre into the connector.

- Use a crimping tool to apply pressure, securing the fibre within the connector.

6) Epoxy

Epoxy termination involves inserting the fibre into the connector filled with epoxy resin, which is then cured to secure the fibre in place.

This method provides a strong and durable bond, making it ideal for applications where long-term stability is essential.

Epoxy terminations require careful handling to ensure that the resin is properly cured, avoiding potential issues with signal transmission.

- Prepare the epoxy according to the instructions.

- Strip and cleave the fibre.

- Apply epoxy to the connector, then insert the fibre.

- Cure the epoxy as directed, ensuring a strong bond.

Terminating fibre optic cables is a precise task that demands attention to detail and adherence to specific procedures. Whether you opt for connectors, splicing, or other methods, the quality of termination directly impacts the efficiency and reliability of the fibre optic network.

For those seeking professional advice or services to ensure the best outcomes in fibre optic termination, do not hesitate to contact us at Altimex.

Our team of experts is ready to assist with your project needs, ensuring your fibre optic installations meet the highest standards of quality and performance.