Electronic Manufacturing Services (EMS) refers to engineering and essential support specialised companies provide to Original Equipment Manufacturers (OEMs).

With the increasing demand for automotive electronics and applications across diverse sectors, EMS is crucial to enhance operational efficiency and cost-effectiveness.

This blog explores what EMS entails, distinguishes it from OEM, and outlines key considerations for selecting an optimal EMS partner.

What are Electronic Manufacturing Services?

EMS constitutes a comprehensive collection of solutions offered by specialised companies, addressing various facets of electronic product development and manufacturing. Their services may include design, prototyping, manufacturing, assembly, and rigorous testing to ensure impeccable quality.

The specific requirements from an EMS partner can vary significantly based on individual business needs. Some may solely seek design expertise, while others require end-to-end solutions, including assembly and testing. EMS bridges the gap, providing the necessary knowledge and resources to streamline these processes efficiently.

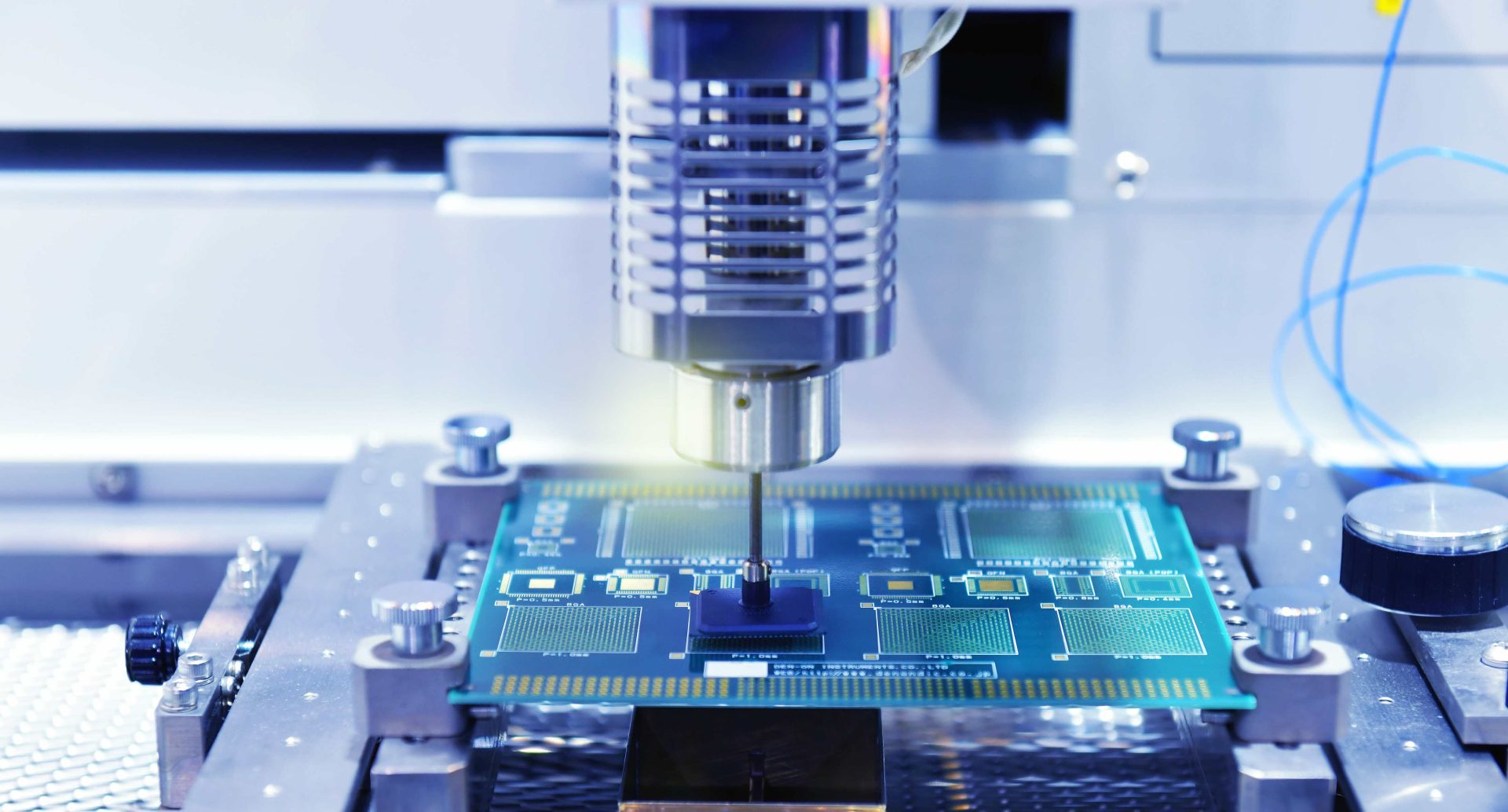

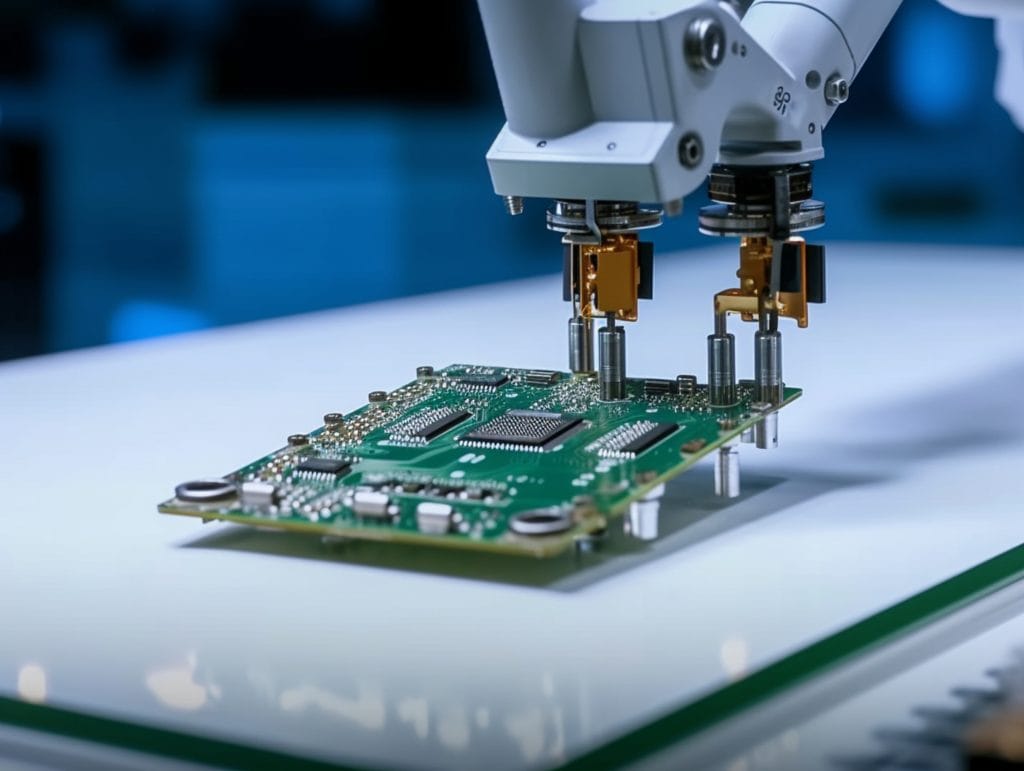

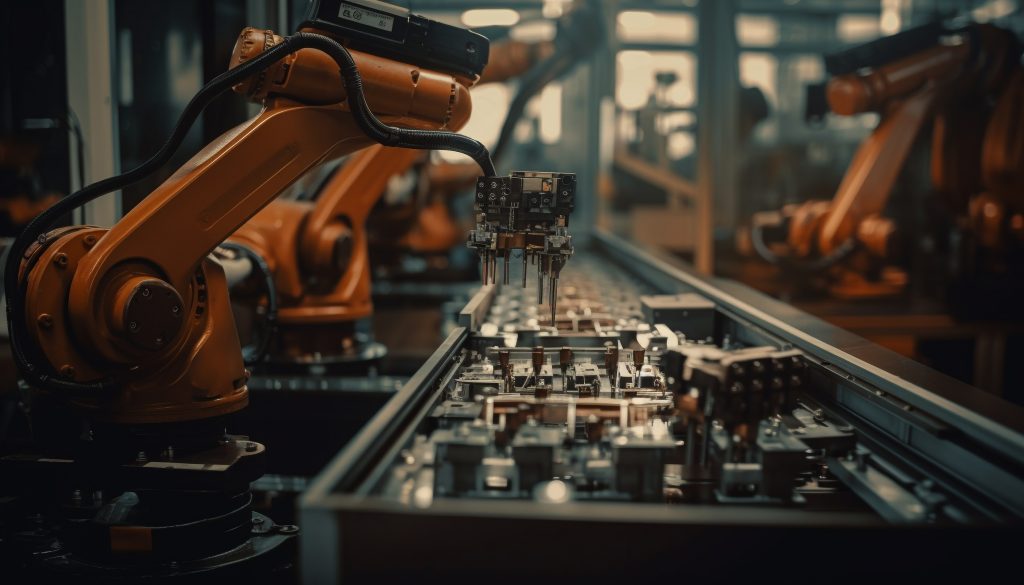

They play a pivotal role in electronic manufacturing, using various forms of automation.

Automation accelerates production and minimises errors, saving substantial time and cost. Additionally, these systems incorporate features that expedite document retrieval, bolstering overall operational efficiency.

Ultimately, with its different levels of automation, EMS optimises workflows and ensures seamless operations.

What are the Differences Between OEM and EMS?

Distinguishing between Original Equipment Manufacturers (OEMs) and Electronic Manufacturing Services (EMS) is paramount.

Firstly, OEMs retain product ownership rights. Their primary focus revolves around product conceptualisation, innovation, and development.

On the other hand, EMS excels in design, production, and supply chain management.

Unlike OEMs, EMS companies do not possess proprietary rights to the products they manufacture. Instead, they collaborate with OEMs to quicken the design phase and efficiently scale production.

One other notable disparity lies in the equipment used.

OEMs typically deploy equipment optimised for longer production runs, necessitating substantial setup time.

In contrast, EMS providers invest in versatile, high-speed machinery designed to facilitate agile and flexible operations, accommodating varying production demands efficiently.

Furthermore, EMS engineers have profound expertise and extensive experience in electronic manufacturing. Their specialised knowledge and focus on optimisation and efficiency make them valuable partners for OEMs wanting support with electronic product development and production.

What Are the Benefits of Electronic Manufacturing Services?

Electronic manufacturing companies have emerged as strategic partners for businesses across many industries, offering advantages that drive operational excellence and cost efficiency.

Cost Savings

Outsourcing EMS operations allows companies to benefit from economies of scale, reducing production costs significantly. EMS providers optimise resources and minimise waste, ultimately leading to cost savings that can be invested elsewhere.

Specialised Services

EMS providers are specialists in their field, offering a comprehensive range of services from design and prototyping to assembly and testing. This specialisation ensures that products are developed and manufactured with precision and expertise.

Automation

Automation is at the core of EMS operations. High-tech machinery and streamlined processes enhance production efficiency, leading to quicker turnaround times and reduced labour costs.

Inventory Management and Data Accessibility

EMS providers excel in managing inventory, tracking sales, and offering automated customer service solutions. They store and manage vast quantities of data, making it easily accessible from multiple locations and aiding in decision-making and supply chain management.

Collaboration with Industry Giants

Even industry giants like Apple continue to rely on EMS providers. The collaboration between OEMs and EMS companies results in improved product quality, enhanced customer service, and the agility needed to respond swiftly to market dynamics.

Expertise and Global Reach

An electronics manufacturer brings deep expertise, access to advanced technologies, and global supply chain management capabilities. They cater to multiple businesses and produce a wide range of products, offering unparalleled versatility.

Different Types of Electronic Manufacturing Applications

EMS are essential across various sectors and applications. The electronic industry’s reach extends into governmental, consumer, and automotive fields, but its influence is even more widespread.

Below are a few examples of the diverse areas where EMS providers offer invaluable support.

Medical

EMS companies facilitate the development and production of medical devices, expediting innovation without compromising quality. This partnership is critical in the medical field, enabling the creation of cutting-edge equipment for mission-critical tasks.

Industrial

In the industrial sector, EMS providers offer expertise in prototyping, testing, and final assembly to swiftly and efficiently bring new products to market. This collaborative effort accelerates product development timelines and ensures the products meet quality standards.

Telecom

EMS is vital in supporting network technologies aiding in data processing and telecommunications. The rapid advancements in this sector require EMS expertise to meet the growing demands of connectivity and communication.

Aerospace and Military

The aerospace and military sectors demand reliable, durable electronic devices to withstand demanding environments. EMS providers excel in enhancing the ruggedness and performance of electronic components, ensuring they meet the strict requirements of these critical industries.

Key Services Offered by EMS Providers

By using an EMS provider, organisations can access a comprehensive selection of services designed to meet the intricate demands of electronic product development and manufacturing. These services include a wide range of critical functions:

Printed Circuit Board Design and Assembly

Printed Circuit Boards (PCBs) are vital in electronic devices, providing the necessary connectivity for components. EMS providers excel in PCB design and assembly, ensuring precise and reliable connections in various electronic applications.

System/Box Assembly

EMS providers offer complete system and box assembly services beyond individual components. This includes integrating multiple components into an assembly, mechanical finishing, box build, wiring, full system and card cage assembly, and even mechanical assemblies such as motors. Rigorous validation testing ensures the assembled systems meet stringent quality standards.

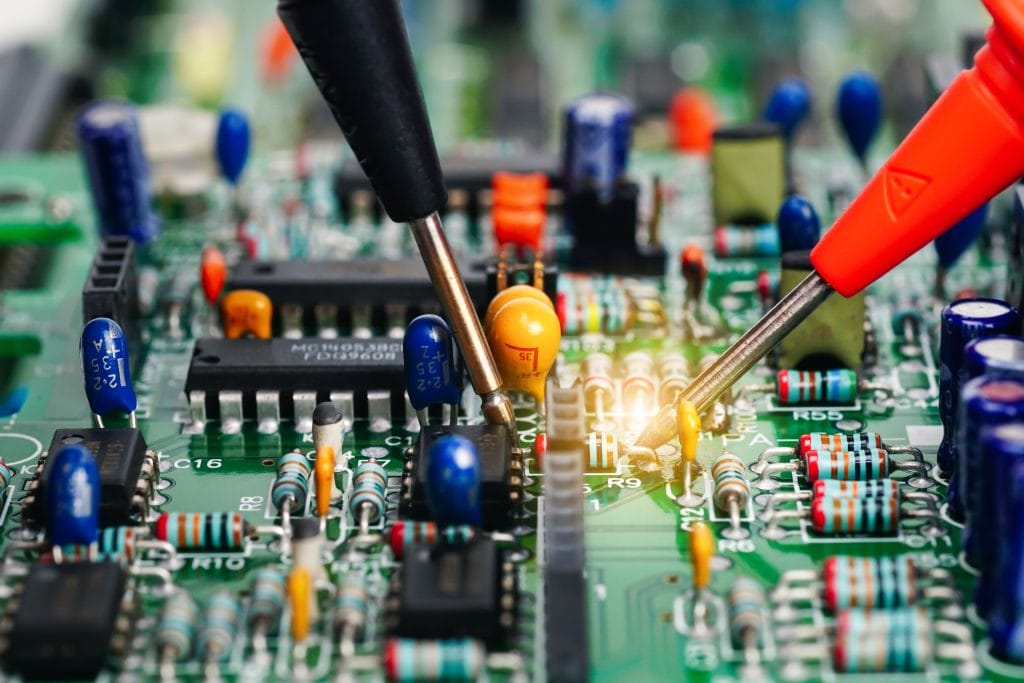

Testing and Quality Control

Ensuring the highest level of quality and reliability is paramount in electronic manufacturing. EMS providers employ various testing methods, including process controls, automated optical inspection, visual inspection, x-ray testing, and functional testing, to identify and rectify any anomalies during production.

Supply Chain Management

As mentioned, providers use automation to streamline supply chain activities. This automation enhances efficiency and equips businesses with a competitive advantage in the marketplace. Effective supply chain management is crucial in meeting production deadlines and cost-effectiveness.

Repairs

In addition to manufacturing, EMS providers often offer repair services, extending the lifecycle of electronic products and reducing the need for costly replacements.

What Factors to Consider When Choosing an EMS Provider

Selecting the right EMS provider is a pivotal decision for businesses to ensure they align with their overall strategic objectives. Achieving optimum collaboration and output requires a comprehensive evaluation of several key factors.

Experience and Expertise

Evaluate the EMS provider’s experience in the industry. For example, Altimex has over 25 years of experience, bringing extensive knowledge and a proven track record and ensuring they understand the intricacies of your specific needs.

Manufacturing Capabilities

Examine the range of electronic manufacturing services offered by the provider. Companies like Altimex provide a broad spectrum of services, allowing businesses to access various solutions from one provider to streamline production.

Quality Control Measures

Quality is paramount in electronic manufacturing, so investigate the EMS provider’s commitment to quality control.

Altimex consistently delivers award-winning solutions, assuring clients of the highest quality standards.

Communication and Collaboration

Effective communication and collaboration are fundamental when collaborating with external companies. EMS providers like Altimex work closely with businesses to understand their unique requirements and ensure satisfaction with the results.

Ultimately, the right EMS provider should integrate into your business strategy, enhancing efficiency, reducing costs, and driving innovation.

Altimex’s EMS Success Stories

As one of the leading EMS providers, Altimex has collaborated with businesses in numerous industries, delivering fantastic results for clients and their electronic needs, and has several successful case studies.

TWM Traffic Control Systems Ltd.

TWM Traffic Control Systems Ltd. wanted tailored solutions to their specific needs. Altimex provided various options, from straightforward flashing controllers to more complex equipment complying with IEC61508 requirements.

Since this partnership, Altimex has received numerous accolades for this electronic project for traffic control systems, highlighting the dedication, honesty and dependability Altimex brought through their work.

Boston Garage

When approached by Boston Garage Equipment Ltd. for dependable solutions within the MOT testing sector, Altimex utilised its cutting-edge Surface Mount Assembly technology to provide complicated modular components for MOT test apparatus. Its expertise in MOT equipment and dedication to quality provided electronic systems for Boston Garage Equipment Ltd. whilst meeting their rigorous expectations.

Altimex and Boston Garage Equipment Ltd. have an excellent working relationship, with the former assisting with portable system development.

Scalemaster

Scalemaster is a company focusing on creating egg-washing systems and wanted high-quality goods to help with their devices. Altimex offered quality electronic manufacturing services, such as a comprehensive product assembly solution to meet Scalemaster’s strict criteria and product expansion.

After Scalemaster launched its Rotomaid Egg Washer device, Altimex became a close associate of the business and continues to support the product.

EMS are essential in modern manufacturing; understanding how they support OEMs and their benefits is crucial. Altimex offers various EMS services to support your organisation, and with over 25 years of experience, we have a diverse service portfolio demonstrating our commitment to quality.

If you want help to elevate your operations, contact Altimex today and see how our electronic design and manufacturing services can support your company.